Development of High Current Draw Lead Transformer Bushings

advertisement

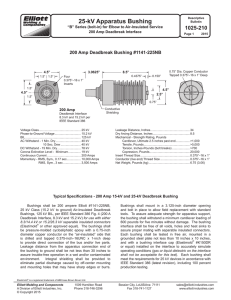

Development of High Current Draw Lead Transformer Bushings Designed in Accordance with IEEE Standards Keith P. Ellis Haefely Trench Nashville, TN 37138 Abstract Historically draw lead bushings, designed in accordance with IEEE Standards were limited in current carrying capacity to a maximum of 400 amperes through 69 kV and 800 amperes 115 kV and above. For most medhirn powertransformersthe high voltage bushings were applied ~“th draw lead conductors. However, the low voltage side of these transformers almost always required bottomcmnnectedbushings.This meant that if these bushing ever had to be removed the transformer oil would be drained and people had to enter the transformertank to disconnect and reconnect the bushing. This procedure was ve~ costly and time consuming, To save these costs and provide a safer working environment bushings with higher draw lead conductorcapabilitywere required. The second factor was the size of the central tube of the bushing, through which the draw lead conductor would pass. For bushings rated 69 kV and below the inside diameter was usually 2.2 centimeters (0.875 inch). This small inside diameter limited the size of the draw lead conductor, limiting the current capacity. The last factor was the draw lead conductor itself. All draw lead conductors applied were flexible cable(s). Flexible cable(s) when limited to a specific diameter will only carry a small amount of current. A solid draw lead conductor with the same outside diameter as cable(s) would carry substantially more current. I. INTRODUCTION II. OBJECTIVES In reviewing the design of the historic draw lead bushing it was found that there were three factors that limited the current carrying capabfity. First was the design of the top terminal. The top terminal design required that the current be transferred horn the draw lead conductor through a threaded stud to the top terminal of the bushing. The size of the draw lead stud and the use of threads are the primary factor for the Ihnited capacity. Before actual development and design work got underway a list of objectives were established. These objectives were grouped into two areas, performance objectives and engineering solutions. The following is the list of petiorrnance objectives: 1. The bushing(s) must comply with the requirements of IEEE C57. 19.00 –1991, IEEE Standard General Requirements and Test Procedures for Outdoor Power Apparatus Bushings and IEEE C57. 19.011991, IEEE Standard Performance Characteristics and Dimensions for Outdoor Apparatus Bushings. 2. The bushing(s) must be interchangeable with existing bottom-connected bushings. Including bottom-connected bushings with current ratings above 1200 amperes, which are not covered by the present bushing standards. 0-7803-5515-6/99/$10.00 (c) 1999 IEEE 3. Installation and application of the bushing(s) must be similar to existing bushing designs. 4, The bushing(s) must be cost effective and be able to compete in the marketplace with bottom-connected bushings. The following is a list of engineering solutions that were identified as obstacles to developing a h&h current draw lead bushings: 1. High current transfer from the draw lead conductor to the top terminal of the bushing. 2. Increasing the inside diameter of the bushing central tube to allow a larger diameter draw lead conductor and still maintain the maximum outside diameter of the bushing below the mounting flange allowed by the standards. 3. Meet these objectives with a proven oil impregnated paper insulation system with aluminum capacitance foil layers. III. TECHNOLOGIES With the objectives defined, the next task was to rlsview the existing bushing technologies around tlhe world. The search for existing technologies was focused on bushings designed and with the accordance nnantiactured in Commission Electrotechnical International Standard 137 for bushings. The search found that most IEC bushing designs offered draw lead currents higher than bushings designed in accordance with IEEE Standards. higher draw lead ratings were These alccomplkhed with the application of solid draw lead conductors. However, IEC designed bushings are rarely produced below 52 kV and a bushing for lower voltage applications are required in the North American market. Many of the IEC bushing designs, using the solid draw lead conductor, still relied on threads for current transfer to the top terminal, limiting the current carrying capabtity. There were some designs that did not use threads, which offered the potential for higher current ratings. One of these IEC designed bushings incorporated the use of multiple spring contacts similar to the ones applied on circuit breakers. This design was evaluated closely and a similar design was incorporated into the design of the new, high current, draw lead bushing. With many years of successfid experience around the world applying solid draw lead conductors it was determined that this concept would be incorporated into the new, high current, draw lead bushing. Together with the multiple spring contacts, the solid draw lead conductor would provide the high current capability we were seeking. IV. DESIGN Using an existing, high current, bottomconnected bushing desig~ which was developed in accordance with the IEEE Standards, the design was modified. The modifications included removing the solid fixed conductor and replacing it with a hollow tube. The tube had nearly the same outside diameter as the solid conductor, which meant that the proven oil impregnated paper condenser with aluminum foils would work well within the limited space. The new bushing would utilize the same explosion resistant, fiberglass lower end insulator, the same mounting flange and the same external porcelain. The only external change was the head of the bushing. The head design for the new bushing had to incorporate the new multiple spring contact assembly and accept the large diameter of the solid draw lead conductor. 0-7803-5515-6/99/$10.00 (c) 1999 IEEE The final design selected for the top terminal with multiple spring contacts allowed for a 133°/0 loading margin above nameplate. The first prototype was a 25 kV bushing with a 1,,500-ampere draw lead rating. This bushing had the same physical dimensions as the 25 kV, 400 ampere draw lead bushing described in Table 2 of IEEE C57.19.01 -1991 After successfid Type testing a 34.5 kV bushing with a 1,500-ampere draw lead rating was designed and Type tested. This bushing had the same physical dimensions as the 34.5 kV, 400 ampere draw lead bushing described in Table 2 of IIEEE C57.19.01 – 1991. Next a 34.5 kV bushing with a 3,000-ampere rating was developed and Type tested. Since 3,000-ampere bushings are not covered by the present IEEE Standards the bushing was designed to be interchangeable with the most common 2,000 and 3,000-ampere bushings presently in use. This interchangeability was accomplished by designing the mounting flange to accept all common-mounting configurations. V. LOADABILITY Once the prototype bushings had pasted all the electrical and mechanical Type Tests a series of temperature tests were preformed to determine the Ioadability of the draw lead conductors. These tests were conducted with flexible cable(s) and removable solid conductors. In addition to tests preformed in accordance with current IEEE Standards, tests were also preformed in accordance with IEC Standards. Table 1 is offered to outline some of the diierences between the two bushing standards. Ambknt temperature I -30 to +40”C I -40 to +40”C +30”C 24 hour average ambient for I +30°c thermal analyse; I +55°C Maximum temperature of I +60”C eonduetorin eon&t with oil Maximum temperature of I eonduetorin eontaet with class A insulationduringoverload Permissibletemperature rise of eonduetorin eontaet with class A insulation I ] I I I +150°c I I Io”c I I 15°c Table 1. Comparisonbetween IEEEand IECbushing standards Another dillerence between these two standards is the transformer oil level during the test. The IEC Standard places the oil level, inside the bushing’s central tube, at l/3rd of the arcing distance of the bushing above the mounting flange. The IEEE Standard requires the transformer oil level to be at the minimum allowable oil level of the specific bushing. (Below the mounting flange) The tests verified that the IEEE test requirements were more demanding on the thermal capabtity of the conductor since the hottest spot temperature on the conductor always occurred in the air space above the oil in the central tube of the bushing. Temperature tests in accordance with the IEEE Standards verified the loadability for each class of bushing and a recommended draw lead conductor-loading guide was developed for the difllerent bushing ratings. 0-7803-5515-6/99/$10.00 (c) 1999 IEEE In table 2 the recommended conductor loading fbr 25 and 34.5 kV class high current draw lead bushings are listed. It is important to bear in mind that these results are for a specific bushing design and bushings of comparable design will have difllerent recommendations. DRAWLEAD CONDUCTOR TYPE - (Copper CABLE - CABLE CABLE - CABLE CABLE CROSS SECTION CABLE 285 [) CABLE SOLID SOLID k nun= 50 70 95 150 185 350 960 1645 MAXIMUMLOADWITH TEMPERATURE INDEX105INSULATION Amps Anlpshnm’ 155 3.10 215 3.07 *EC - -Jn Au> .4 ./7 I 385 ..-. 4XJ 1 2.57 - .- I L.LJ I ,cAll 04U 2.45 a “CA lx) *C -%A I L.14 1.56 1.83 1500 3000 Table 2. Draw lead conductorloading for 25 and 34.5 kV bushings “~able 2 is based on having the draw lead conductor insulated with index 105 insulation. An additional loading capability can be obtained when the draw lead conductor is insulated with index 155 insulation. Tests have proven that 20°/0 a~dditional loading can occur before the bushing’s index 105 insulation is subjected to a total hottest of 105°C. This provides spot temperature increased loadability of 20°/0 over nameplate v~ues. Solid conductors that are in direct contact with the central tube of the bushing do not require insulation and provide this increased capability. in addition to temperature testing the 25 and 34.5 kV class bushings temperature tests were also conducted on higher voltage bushings with the r-e technology. The results have proven that bushings as large as 500 kV can be provided with draw lead conductor ratings of over 1600 amperes. This is more than twice present capabilities of bushings design in accordance with present IEEE bushing standards. VI. APPLICATION The solid draw lead conductor use in the bushing is designed with a split, located 1.2 centimeters (% inch) below the gasket surface of the mounting flange. The split allows the conductor to taken apart when transporting the transformer with the bushings removed. This split has led to calling the conductor a “Split-Conductor”. Application of the “Split-Conductor” on bushings, 25 kV through 69 kV, for new or remanufactured transformers requires some special consideration at the time the transformer is designed. The inside diameter of the mounting flange does not allow enough space to assemble or disassemble the “Split-Conductor”. For this reason the transformer design must allow the “Split-Conductor” to be lifted vertically 15.24 centimeters (6 inches). This additional vertical lift capability is not required when the bushing is applied as a replacement bushing on an existing transformer. The only other application consideration is the design of the mounting flange shipping cover. The shipping cover will require a supporting bar welded to the center of the underside. This supporting bar must have matching threaded holes to allow the inboard section of the “SplitConductor” to be secured during transport of the transformer. This application consideration would apply to all voltage class bushings, which are equipped with a “Split-Conductor”. In addition some provisions should be considered to lift the shipping cover when the bushings are installed. 0-7803-5515-6/99/$10.00 (c) 1999 IEEE VII. INSTALLATION IX. ACKNOWLEDGEMENTS Installing high current draw lead bushings for the first the is exactly the same as installing a lmttom-cormected bushing. The bushing is fixed to the mounting flange and the transformer’s winding leads are connected to the bottom terminal at the end of the “Split-Conductor”. The author gratefidly acknowledges the contribution of the following individuals in the development of these new bushings, for without their expertise in all aspects of bushing desig~ these bushing may never have been developed: Clnce the bushing has been installed, future removal or replacement is accomplished the same m any other draw lead bushing. Just remove the top terminal, support the draw lead conductor and slip the bushing out of the transformer tank. 13raining the transformer oil is not required and no person has to enter the transformer tank to disconnect the bushing. Dr. Volker Karius Haefely Trench AG Basel Switzerland Heinz-J(irgen Jeske Haefely Trench AG Basel, Switzerland JoachimSchmid HaefelyTrenchAG Basel, Switzerland Peter D. Zhao HaefelyTrench Scarborough,Ontario Rolf Fluri Haefely Trench AG Basel, Switzerland Christian Schiegel Haefely Trench AG Basel, Switzerland X. BIOGRAPHY VIII. SUMMARY After more than three years of dedicated work by a number of talented and experienced Engineers a high current, low voltage, draw lead bushing, designed in accordance with IEEE Standards, has become a reality. This effort was borne out of the needs of the Electric Power Industry to lower costs and improve worker safety. AU of the stated objectives have been met. 13ushings, designed in accordance with IEEE fltmdmds, draw lead with high current, conductors are now available through 345 kV. Higher current, draw lead conductor bushings are being considered but conductor weight may make them impractical. Actual field experience has shown that transformers delivered with high current, draw lead bushings can substantially reduce installation time. The potential saving, if the bushing must be replaced in field, has not yet been seen due to lack of field problems. It has been estimated that these savings will be substantial. Keith P. Ellis was born in Vallejo, California, on October’ 17, 1948.He graduatedfrom Mare Island Navel Shipyard, Vallejo, California with a journeyman certificate in machine technology. Attended University of Californirq majoring in Mechanical Engineering. After serving in the US Navy during the Vietnam War, he joined RTEIASE4 Waukesha, WI. While with RTE/ASEA he worked in the engineering and marketing. In 1977 he was promoted to field sales for RTE and RTIYASEA in upstate New York where he achieved the position of Senior Sales Engineer. In 1986 he returned to ASEA Electric, Waukesha, WI as Manager of Transformer Components, Marketing and Sales. In 1989 he was transferred to ABB Power T & D Company where he held the position of OEM Sales Manager for the Components Division. In 1992 he joined Haefely Trench, as Manager of Marketing and Sales for North America. In 1995 he was promoted to the position of Product Manager, Bushings. He is a Member of IEEE/PES and takes particular interest in component applications to power transformers with special interest in high voltage bushings and on-load tap changers. 0-7803-5515-6/99/$10.00 (c) 1999 IEEE