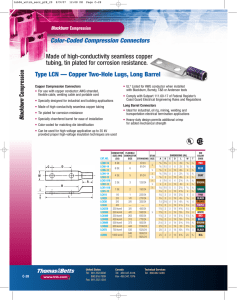

Compression Connectors

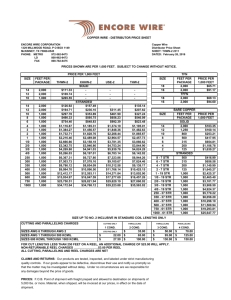

advertisement