Switched Reluctance Motor - University of Technology Sydney

advertisement

48550 Electrical Energy Technology

Switched Reluctance Motor

1. Introduction

The reluctance motor is an electric motor in which torque is produced by the tendency

of its moveable part to move to a position where the inductance of the excited

winding is maximized. The origin of the reluctance motor can be traced back to 1842,

but the “reinvention” has been possibly due to the advent of inexpensive, high-power

switching devices.

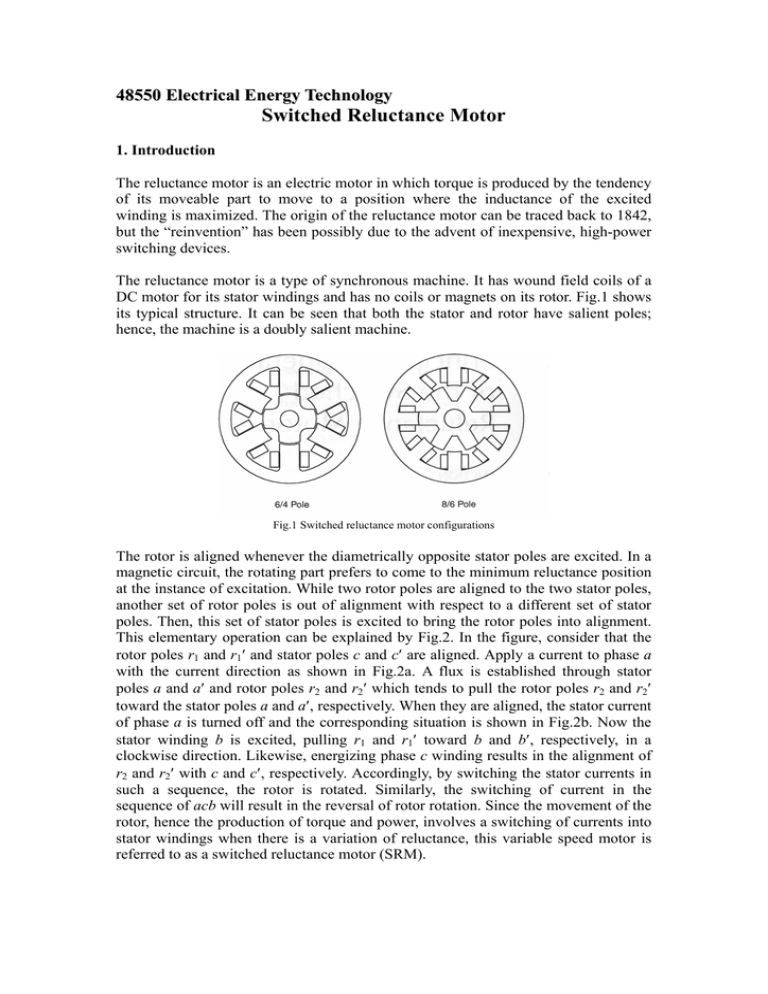

The reluctance motor is a type of synchronous machine. It has wound field coils of a

DC motor for its stator windings and has no coils or magnets on its rotor. Fig.1 shows

its typical structure. It can be seen that both the stator and rotor have salient poles;

hence, the machine is a doubly salient machine.

Fig.1 Switched reluctance motor configurations

The rotor is aligned whenever the diametrically opposite stator poles are excited. In a

magnetic circuit, the rotating part prefers to come to the minimum reluctance position

at the instance of excitation. While two rotor poles are aligned to the two stator poles,

another set of rotor poles is out of alignment with respect to a different set of stator

poles. Then, this set of stator poles is excited to bring the rotor poles into alignment.

This elementary operation can be explained by Fig.2. In the figure, consider that the

rotor poles r1 and r1′ and stator poles c and c′ are aligned. Apply a current to phase a

with the current direction as shown in Fig.2a. A flux is established through stator

poles a and a′ and rotor poles r2 and r2′ which tends to pull the rotor poles r2 and r2′

toward the stator poles a and a′, respectively. When they are aligned, the stator current

of phase a is turned off and the corresponding situation is shown in Fig.2b. Now the

stator winding b is excited, pulling r1 and r1′ toward b and b′, respectively, in a

clockwise direction. Likewise, energizing phase c winding results in the alignment of

r2 and r2′ with c and c′, respectively. Accordingly, by switching the stator currents in

such a sequence, the rotor is rotated. Similarly, the switching of current in the

sequence of acb will result in the reversal of rotor rotation. Since the movement of the

rotor, hence the production of torque and power, involves a switching of currents into

stator windings when there is a variation of reluctance, this variable speed motor is

referred to as a switched reluctance motor (SRM).

Fig.2 Operation of switched reluctance motor

(a) Phase c aligned and (b) Phase a aligned

2. SRM Configurations

Switched reluctance motors can be classified as shown in Fig.3. The initial

classification is made on the basis of the nature of the motion (i.e., rotating or linear).

Fig.3 Classification of SRM

2.1 Rotary SRM

The rotary machine-based SRMs are further differentiated by the nature of the

magnetic field path as to its direction with respect to the axial length of the machine.

If the magnetic field path is perpendicular to the shaft, which may also be seen as

along the radius of the cylindrical stator and rotor, the SRM is classified as radial field.

When the flux path is along the axial direction, the machine is called an axial field

SRM.

Radial field SRMs are most commonly used. They can be devided into shorter and

longer flux paths based on how a phase coil is placed. The conventional one is the

long flux path SRMs, in which the phase coil is placed in the diametrically opposite

slots, as shown in Fig.1. In the shorter flux path SRMs, the phase coil is placed in the

slots adjacent to each other, as shown in Fig.4. Short flux path SRMs have the

advantage of lower core losses due to the fact that the flux reversals do not occur in

stator back iron in addition to having short flux paths. However, they have

disadvantage of having a slightly higher mutual inductance and a possible higher

uneven magnetic pull on the rotor.

Fig.4 Short flux path SRM with 10/8 poles

The axial configuration of a SRM is shown in Fig.5. This type of SRMs is ideal for

applications where the total length may be constrained, such as in a ceiling fan or in a

propulsion application. The disadvantage of this configuration is that the stator

laminations have to be folded one on top of the other, unlike the simple stacking of

laminations in the radial field configuration.

Fig.5 Axial field switched reluctance motor

2.2 Single-Phase SRM

Single-phase SRMs are of interest as they bear a strong resemblance to single phase

induction and universal machines and share their low-cost manufacture as well.

High-speed applications are particularly appealing for single-phase SRMs. When the

stator and rotor poles are aligned, the current is turned off and the rotor keeps moving

due to the stored kinetic energy. As the poles become unaligned, the stator winding

again is energized, producing an electromagnetic torque. A problem with single-phase

SRM operation arises only when the stator and rotor poles are in alignment at

standstill or the rotor is at a position where the torque produced may be lower than the

load torque at starting. This can be overcome by having a permanent magnet on the

stator to pull the rotor away from the alignment, or to an appropriate position, to

enable the generation of maximum electromagnetic torque, as shown in Fig.6.

The single-phase SRMs operate with a maximum duty cycle of 0.5, and therefore,

they have a torque discontinuity that results in high torque ripple and noise.

Applications, which are insensitive to this drawback, such as hand tools and home

appliances, are ideal for this machine.

Fig.6 Single-phase SRM with permanent magnet to enable starting

2.3 Linear SRMs

Linear switched reluctance motors (LSRMs) are the counterparts of the rotating

SRMs. In fact, the linear switched reluctance motor is obtained from its rotary

counterpart by cutting along the shaft over its radius and rolling them out. Fig.7 shows

the configuration of a three phase LSRM.

Fig.7 Three phase linear switched reluctance motor

3. Principle of Operation

The torque production in the switched reluctance motor can be explained using the

elementary principle of electromechanical energy conversion. In the case of a rotating

machine, the incremental mechanical energy in terms of the electromagnetic torque

and change in rotor position can be written as:

ΔWm = Te Δθ

(1)

where Te is the electromagnetic torque and Δθ the incremental rotor angle. Therefore,

the electromagnetic torque can be obtained by:

ΔWm

(2)

Te =

Δθ

For the case of constant excitation (i.e., when the mmf is constant), the incremental

mechanical energy is equal to the change of magnetic coenergy, Wf′:

ΔWm = ΔW f′

(3)

By the theory of electromagnetic field, if no magnetic saturation exists, the coenergy

at any position in the motor can be expressed by:

1

L(θ , i )i 2

(4)

2

where L(θ, i) is the stator inductance at a particular position, and i the stator phase

current. Hence, the electromagnetic torque is:

'

'

ΔWm ΔW f ∂W f ∂L(θ , i ) i 2

(5)

Te =

=

=

=

⋅

Δθ

Δθ

∂θ

∂θ

2

Equation (5) has the following implications:

1. The torque is proportional to the square of the current and hence, the current can

be unipolar to produce unidirectional torque. This is a distinct advantage in that

only one power switch is required for the control of current in a phase winding

and thereby makes the drive economical.

2. Since the torque is proportional to the square of the current, it has a good

starting torque.

3. Because the stator inductance of a stator winding is a function of both the rotor

position and stator current, thus making it nonlinear, a simple equivalent circuit

development for SRM is not possible.

4. A generation action is made possible with unipolar current due to its operation

on the negative slope of the inductance profile. As a result, this machine is

suitable for four-quadrant operation with a converter.

5. Because of its dependence on a power converter for its operation, this motor is

an inherently variable-speed motor drive system.

W f' =

4. Stator Inductance

The torque characteristics of switched reluctance motor are dependent on the

relationship between the stator flux linkages and the rotor position as a function of the

stator current. A typical phase inductance vs. rotor position is shown in Fig.8 for a

fixed phase current. The inductance corresponds to that of a stator-phase coil of the

motor neglecting the fringe effect and saturation. The significant inductance profile

changes are determined in terms of the stator and rotor arcs and number of rotor poles.

From Fig.3a and b, the various angles are derived as:

⎤

1 ⎡ 2π

θ1 = ⎢ − ( β s + β r ) ⎥

2 ⎣ Pr

⎦

θ 2 = θ1 + β s

θ3 = θ 2 + ( β r − β s )

(8)

θ 4 = θ3 + β s

(9)

θ 5 = θ 4 + θ1 =

2π

Pr

(6)

(7)

(10)

where βs and βr are the stator and rotor pole arcs, respectively, in most case βr > βs, and Pr is the

number of rotor poles.

Four distinct inductance regions emerge:

1. 0 ~ θ1 and θ4 ~ θ5: the stator and rotor poles are not overlap, and the

inductance is minimum and almost a constant. Hence, these regions do not

contribute to torque production.

2. θ1 ~ θ2: Poles overlap, so that the flux path is mainly through the stator and

rotor laminations. This increases the inductance with the rotor position and

gives it a positive slope. A current impressed in the winding during this region

produces a positive torque. This region comes to an end when the overlap of

poles is complete.

3. θ2 ~ θ3: During this period, movement of rotor pole does not alter the

complete overlap of the stator pole. This has the effect of keeping the

inductance maximum and constant. Therefore, torque generation is zero. In

spite of this fact, it serves a useful function by providing time for the stator

current to come to zero or lower levels when it is commutated, thus

preventing negative torque generation in the negative slope region of the

inductance.

4. θ3 ~ θ4: the rotor pole is moving away from overlapping the stator pole in this

region and the inductance decreases, making a negative slope of the

inductance region. The operation of the machine in this region results in

negative torque.

Fig.8 Inductance vs. rotor position

It is not possible to achieve the ideal inductance profile shown in Fig.8 in an actual

motor due to saturation. Saturation causes the inductance profile to curve near the top

and thus reduces the torque constant. For rectangular currents, it can be seen that the

motoring torque is produced for a short duration in pulsed form, resulting in a large

torque ripple. This can create problems of increased audible noise, fatigue of the shaft,

and possible speed oscillations. However, the torque ripples can be minimized by

designing the machine such that the inductance profiles of two succeeding phases

overlap during the ending of one and the beginning of the other. In turn, this requires

the correct choice of number of stator and rotor poles and their pole arcs. An

alternative technique to reduce the torque ripples is to shape the current.

5. Equivalent Circuit

An elementary equivalent circuit for the SRM can be derived neglecting the mutual

inductance between the phases as follows. The applied voltage to a phase is equal to

the sum of the resistive voltage drop and the rate of the flux linkages and is given as:

d λ (θ , i )

V = Rs i +

(11)

dt

where Rs is the resistance per phase, and λ the flux linkage per phase given by:

λ = L(θ , i)i

(12)

where L is the inductance dependent on the rotor position and phase current. Then, the

phase voltage is:

d{L(θ , i )i}

di

dθ dL(θ , i )

V = Rs i +

= Rs i + L(θ , i ) + i

dt

dt

dt dθ

(13)

di dL(θ , i )

= Rs i + L(θ , i ) +

ω mi

dt

dθ

In this equation, the three terms on the right-hand side represent the resistive voltage

drop, inductive voltage drop and induced emf, respectively. The induced emf, e, is

expressed as:

dL(θ , i )

e=

ω mi = K bω mi

(14)

dθ

Fig.9 illustrates the equivalent circuit for one phase of the SRM.

Fig.9 Single phase equivalent circuit of SRM

6. SRM Drive System

A typical SRM drive system is shown in Fig.10. It is made up of four basic

components: power converter, control logic circuit, position sensor and the switched

reluctance motor.

Fig.10 Structure of SRM drive sytem

6.1 Power Converters for SRMs

Since the torque in SRM drives is independent of the excitation current polarity, the

SRM drives require only one switch per phase winding. Moreover, unlike the ac

motor drives, the SRM drives always have a phase winding in series with a switch.

Thus, in case of a shoot-through fault, the inductance of the winding limits the rate of

rise in current and provides time to initiate the protection. Furthermore, the phases of

SRM are independent and, in case of one winding failure, uninterrupted operation is

possible. Following are some configurations of converters used in SRM drives.

Asymmetric Bridge Converter

Fig.10a shows the asymmetric bridge converter. Turning on the two power switches in

each phase will circulate a current in that phase of SRM. If the current rises above the

commanded value, the switches are turned off. The energy stored in the motor phase

winding will keep the current in the same direct until it is depleted. The waveforms

are shown in Fig.10b and c with different switching strategies.

Fig.10 Asymmetric converter for SRM and operation waveforms

(n+1) switches and diode configuration

Utilization of the power devices is poor in the asymmetric bridge converter. A more

efficient converter topology is shown in Fig.11, which is called (n+1) switch and

diode configuration. When T1 and T2 are turned on, phase A is energized by applying

the source voltage across the phase winding. The current can be limited to the set

level by controlling either T1 or T2, or both. Similarly, phase B can be energized by

T2 and T3. The merit of this converter is higher utilization of power devices due to

the shared switch operation. Nevertheless, the circuit provides restricted current

control during overlapping phase currents.

Fig.11 (n+1) switches converter topology

Bifilar Type Drive Topology

Fig.12a shows a converter configuration with one power switch and one diode per

phase but regenerating the stored magnetic energy to the source. This is achieved by

having a bifilar winding with the polarity as shown in the figure. The various timing

waveforms of the circuit are shown in Fig.12b. It is shown that the voltage across the

power switch can be very much higher than the source voltage. A disadvantage of this

drive is that the SRM needs a bifilar winding, which increases the complexity of the

motor.

(a)

Fig.12 Bifilar type drive and operation waveforms

C-Dump Converter

The C-dump converter is shown in Fig.13a with an energy recovery circuit. The

stored magnetic energy is partially diverted to the capacitor Cd and recovered from it

by the single quadrant chopper comprising of Tr, Lr and Dr and sent to the DC source.

Fig.13b shows the waveforms of this converter.

This configuration has the advantage of minimum power switches allowing

independent phase current control. The main disadvantage is that the current

commutation is limited by the difference between voltage across Cd, vo and the DC

link voltage. Furthermore, the energy circulating between Cd and the DC link results

in additional losses in the machine.

Fig.13 C-Dump Converter for SRMs

6.2 Position Sensors

In the SRM drives, rotor position is essential for the stator phase commutation and

advanced angle control. The rotor position is usually acquired by the position sensors.

The commonly used position sensors are phototransistors and photodiodes, Hall

elements, magnetic sensors, pulse encoders and variable differential transformers.

Phototransistor Sensors

The phototransistor sensor is based on the photoelectric principle. Fig.14 shows the

basic structure of the phototransistor sensor.

Fig.14 Phototransistor sensors

As shown in the figure, a revolving shutter with a 120° electric angle gap is installed

on the rotor shaft, rotating with the rotor of the SRM. Phototransistors of the same

number as the motor phases (three phases in the figure) are fixed on the stator. When

the gap is aligned with the phototransistor PT1, the phototransistor will generate a

current due to the light, while phototransistor PT2 and PT3 have only a very small

leakage currents because the light is blocked by the revolving shutter. In this case, the

stator phase associate with PT1 should be turned on. Similar situation will occur when

the gap of revolving shutter is aligned with PT2 or PT3.

Hall Position Sensors

The function of a Hall sensor is based on the physical principle of the Hall effect

named after its discoverer E. H. Hall: It means that a voltage is generated transversely

to the current flow direction in an electric conductor (the Hall voltage), if a magnetic

field is applied perpendicularly to the conductor.

Fig.15 Hall position sensor

A typical structure of Hall position sensor for three phase motor is illustrated in Fig.15.

It is made up of three Hall components and a rotating plate with permanent magnet

fixed on the rotor shaft. Similar to the gap of the phototransistor sensors, the

permanent magnet on the rotating plate is installed suitably so that the output of the

Hall components can indicate the proper rotor position for the phase current control.

7. Control of SRM

Given the inductance profile shown in Fig.16, for motoring operation, the phase

windings are excited at the onset of increasing inductance. The torque produced in

one phase for motoring and regeneration is also shown in Fig.14. An average torque

will result due to the combined instantaneous values of torque pulses of all machine

phases (Fig.17).

Fig.16 Motoring and regeneration actions of the SRM

Fig.17 Average torque of three-phase SRM

From Fig.16, it can be seen that the average torque is controlled by adjusting the

magnitude of winding current Ip or by varying the dwell angle θd. To ensure

instantaneous torque production it is essential that the desired current come on at the

instant of increasing inductance. From a practical point of view, the current cannot

instantaneously rise or fall in an R-L circuit. This necessitates advanced application of

voltage for starting the current and advanced commutation to bring the current to zero

before a negative sloping inductance profile is encountered. Hence, the actual current

waveforms are likely to be as shown in Fig.18. The voltage is applied in advance by

θa and the current turn-off is initiated in advance by θco. Note that θa and θco are

dependent on the magnitude of the peak winding current ip and the rotor speed. Fig.19

shows the typical current waveforms for various advanced angles and dwell angles.

With a suitable current control, the torque/speed characteristics can be obtained as

shown in Fig.20. In the speed range from 0 to ωb, where is the base speed or the rated

speed at which the induced emf balances with the terminal voltage, the produced

torque can be constant. When the speed is in the range from ωb to ωd, the produced

average torque decreases but the output power Tω can keep constant by increasing the

dwell angle θd. When the operation speed is over ωd, even power cannot be

maintained constant. In this case, Tω2 can be constant by keeping the maximum θd.

Fig.18 Current control of SRM drive

Fig.19 Typical current waveforms at different speeds and advance ahnles

Further Readings:

[1] T. J. E. Miller, Switched Reluctance Motors and Their Control, Magna Physics

Publishing and Clarendon press, Oxford, 1993

[2] R. Krishnan, Switched Reluctance Motor Drives: Modelling, Simulation,

Analysis, Design, and Applications, CRC Press, 2001

Fig.20 Torque/speed characteristics of SRM

Exercises:

See the problems and solutions on the webpage.