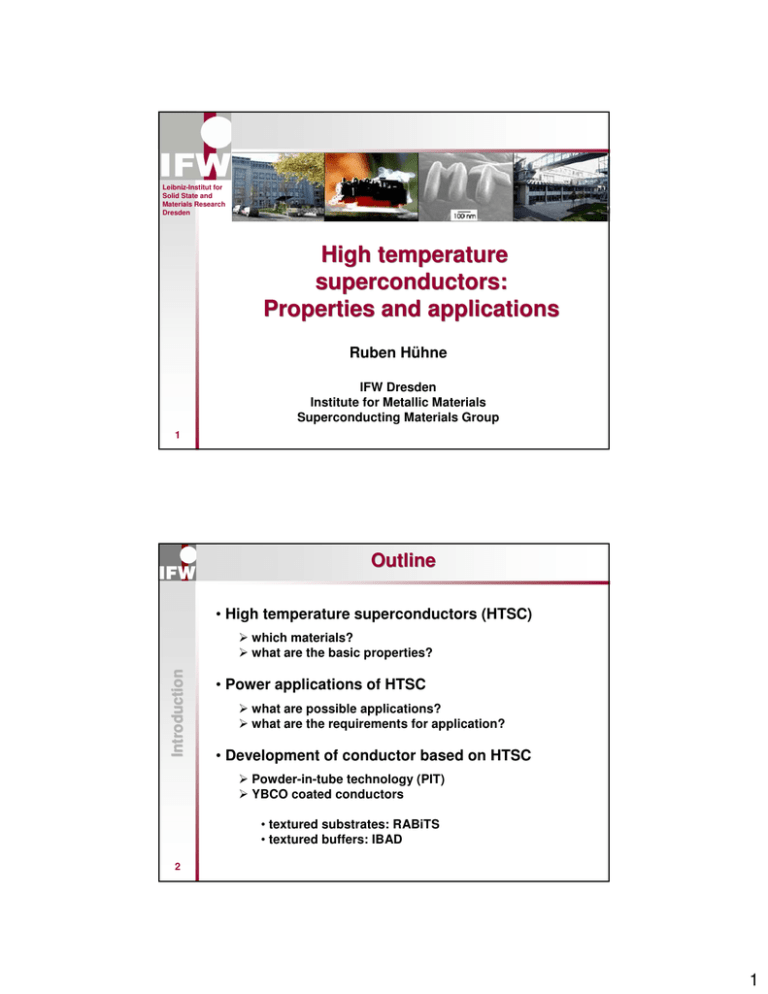

High temperature superconductors: Properties and applications

advertisement

Leibniz-Institut for Solid State and Materials Research Dresden High temperature superconductors: Properties and applications Ruben Hühne IFW Dresden Institute for Metallic Materials Superconducting Materials Group 1 Outline • High temperature superconductors (HTSC) Introduction which materials? what are the basic properties? • Power applications of HTSC what are possible applications? what are the requirements for application? • Development of conductor based on HTSC Powder-in-tube technology (PIT) YBCO coated conductors • textured substrates: RABiTS • textured buffers: IBAD 2 1 Basic properties of HTSC Outline • High temperature superconductors (HTSC) which materials? what are the basic properties? • Power applications of HTSC what are possible applications? what are the requirements for application? • Development of conductor based on HTSC Powder-in-tube technology (PIT) YBCO coated conductors • textured substrates: RABiTS • textured buffers: IBAD 3 Superconductivity Liquification of Helium H. Kamerlingh Onnes, Leiden (1908) Discovery of „Superconductivity“: ideal conductivity Kamerlingh Onnes H. Kamerlingh Onnes, Leiden (1911) Many metals become superconducting at low temperatures Temperature (K) Basic properties of HTSC Discovery of Superconductivity Liquid hydrogen: 20 K Year of discovery Step in the electrical resistivity of Hg: critical temperature TC 4 Current transport without losses possible Cooling with liquid helium necessary 2 Basic properties of HTSC High temperature superconductors 77 K Ba-La-Cu-O compound: J. G. Bednorz, K. A. Müller, Z. Physik, B 64 (1986) 189 Ba-La-Cu-O Cooling with liquid nitrogen possible compound commercial potential 5 TC (K) YBa2Cu3O7-δ Y-123 Bi2Sr2CaCu2O8 Bi-2212 84 Bi2Sr2Ca2Cu3O10 Bi-2223 110 TlBa2Ca2Cu3O10 Tl-1223 125 HgBa2Ca2Cu3O10 Hg-1223 133 92 High temperature superconductors Bi(Pb)-2212 REBCO REBa2Cu3O7-x RE: Y, Nd, Er, Gd, Eu… Bi(Pb)-2223 2212 ≈ (Bi,Pb)2Sr2CaCu2Ox (x ≈ 8) 2223 ≈ (Bi,Pb)2Sr2Ca2Cu3Ox (x ≈ 10) O CuO2-planes responsible for superconductivity Ba Y Properties show high anisotropy Ca Bi Sr Cu O 6 Cu Ceramics: layered perovskite material (2-dimensionality) c = 11.68 Å Basic properties of HTSC BiSCCO TC = 85 K TC = 110 K b = 3.88 Å a = 3.83 Å TC = 92 K 3 High temperature superconductors Dependence of the superconducting properties on O doping Basic properties of HTSC Anisotropy of the resistivity 7 HTSC in magnetic fields 8 superconductor type II nc µ0HC2 (T) µ0H (T) Basic properties of HTSC B(T) phase diagramm of type II superconductors sc Mixed phase (Shubnikov) Meissner phase magnetic field TC µ0HC1 (T) flux line T (K) type II TC (K) µ0HC2 (T) 9.3 0.3 Nb3Sn 18.0 24.5 Nb3Ge 23.2 38.0 MgB2 39.0 17.0 Y-123 92.0 150 Bi-2223 110.0 108 Nb Φ0 normal conducting core penetration depth λ shielding currents Cooper pair density n flux quantum -15 2 F 0 = 2 ·10 Tm magnetic field B r vortex coherence lenghth ξ 4 HTSC in magnetic fields HTS sc µ0Hirr µ0H (T) Basic properties of HTSC B(T) phase diagram of superconductors: critical fields nc vortex liquid vortex glass µ0HC2 vortex lattice applied magnetic field penetrates the superconductor in form of vortices µ0HC1 current leads to Lorenz force on vortex lines movement of vortices leads to dissipation: Irreversibility line pinning of the vortices necessary for high critical currents in magnetic fields incorporation of nanoscaled pinning centres T (K) Φ0 pointlike pinning centers 9 core diameter ~ 2ξ vortex HTSC in magnetic fields Basic properties of HTSC Irreversibility line Properties of the vortices are dependant on the crystal structure of the material Bi-2223 YBCO BSCCO-2223 YBCO CuO2 d CuO2 CuO2 CuO2 CuO2 YBCO is the preferred material for applications at 77 K in higher magnetic fields d CuO2 CuO2 CuO2 CuO2 CuO2 CuO2 CuO2 d~ 2ξ 10 CuO2 CuO2 B 3D flux line d > 2ξ 2D pancake vortices 5 Critical current density Basic properties of HTSC Current-voltage characteristic of superconductors I U ( I ) = U 0 I0 n Critical current Ic is dependant on temperature and magnetic field Critical current density Jc: Ic divided by cross section of the superconductor Engineering current density Je: 11 Ic divided by cross section of complete conductor Critical current density Anisotropy 9 3x10 B = 1 T, φ = 0° B = 4 T, φ = 0° B = 1 T, φ = 90° B = 4 T, φ = 90° 9 2x10 2 Jc (A/m ) Basic properties of HTSC Critical current density 9 1x10 0 -90 12 -45 0 45 90 θ (°) 6 Basic properties of HTSC HTSC grain boundaries YBCO Bi2212 Measurement on bicrystals Bi2223 Hilgenkamp et al., Rev. Mod. Phys. 74 (2002) 485 High Jc in polycrystalline materials require strong biaxial texture 13 HTSC grain boundaries Θ Basic properties of HTSC Origin of Jc-limitation at grain boundaries: Symmetry of the order parameter Band bending due to interface charging d=b/2sin(Θ/2) ≈ b/Θ d Für b=0.38nm Θ=8° ⇒ d=2.7nm (100) (100) (010) (010) Depletion zone KG 14 Microstructure: • Strain fields around dislocations, • Distorted areas in large angle grain boundaries Deviations from ideal stoichiometry • regions with oxygen vacancies • disorder • localised states Direct suppression of pairing mechanism Reason: Extremly short coherence length ξ and low charge carrier density in HTSC EL Tcmax TcKorn 0 EF EV λ TF Tc d λ TF Hilgenkamp et al., Rev. Mod. Phys. 74 (2002) 485 7 Basic properties of HTSC Other „new“ superconductors MgB2 Fe-pnictides and -chalcogenides Phase known since the early 50‘s Superconductivity discovered 2008 Jones et al., J. Am. Chem. Soc. 76 (1954) 1434 Kamihara et al., J. Amer. Chem. Soc. 130 (2008) 3296 Superconductivity discovered in 2001 Nagamatsu et al., Nature 410 (2001) 63 Tc = 39 K: highest Tc for binary superconductors LaO1-xFxFeAs GdO1-xFxFeAs SmO1-xFxFeAs Ba1-xKxFe2As2 FeSe1-xTex … Tc ~ 26 K Tc ~ 53 K Tc ~ 55 K Tc ~ 38 K Tc ~ 15 K no weak link behavior at grain boundaries in contrast to cuprates 15 large coherence length ξab = 7-10 nm Applications of superconductors Outline • High temperature superconductors (HTSC) which materials? what are the basic properties? • Power applications of HTSC what are possible applications? what are the requirements for application? • Development of conductor based on HTSC Powder-in-tube technology (PIT) YBCO coated conductors • textured substrates: RABiTS • textured buffers: IBAD 16 8 Applications of superconductors Application of classical superconductors Application in medical and analytical devices Medicine: Magnetic Resonance Imaging (MRI) of soft tissues like organs, cartilages, tendons etc. >3000 t NbTi per year Analytics: Nuclear Magnetic Resonance (MNR) spectroscopy >500 t Nb3Sn per year 17 Applications of superconductors Application of classical superconductors Magnets for research devices • Accelerators in particle physics • Reactors for nuclear fusion 18 9 Applications of superconductors Power applications of HTSC Generator Cable Transformer Higher current density lower weight @ same power Lower losses / higher efficiency Environmental friendly Motor copper 19 Applications of superconductors Power applications of HTSC Ship populsion motors 20 10 Applications of superconductors Power applications of HTSC Superconducting cable 350 m long cable at 34.5 kV and 800 A in real network Made form BiSCCO and YBCO based conductors 21 Required properties for different power applications Current limiter 106 Jc [A/cm²] Applications of superconductors Power applications of HTSC Cable Fusion magnets 105 MRI magnets 104 Transformers NMR-Spectrometer Typical YBCO layer on technical substrates at 77 K 10³ 10² 5 22 Generators, Motors 10 15 20 B [T] 11 Applications of superconductors Application of HTSC 23 Main requirements on HTSL conductors for application • Mechanical flexible conductor (for coils etc.) metal-ceramic heterostructure • High current transport capability at: - highest application temperature (above 77 K) - highest magnetic fields strongly textured superconductors defined incorporation of pinning centres • Availability in long length (several km necessary for demonstrators) • Cheap production of long length necessary robust and fast methods low cost materials • Other requirements for certain application: - low ac-losses - high mechanical strength - reduced anisotropy Preparation of HTSC conductors Outline • High temperature superconductors (HTSC) which materials? what are the basic properties? • Power applications of HTSC what are possible applications? what are the requirements for application? • Development of conductor based on HTSC Powder-in-tube technology (PIT) YBCO coated conductors • textured substrates: RABiTS • textured buffers: IBAD 24 12 Preparation of HTSC conductors Powder-in-Tube (PIT) Technology Preparation of BiSCCO and MgB2 conductors Precursor Mixture of Base Compounds • Sol-gel methods • Mechanical alloying e.g Bi-Pb-Sr-Ca-Cu-O powder with Bi-2223 composition or Mg, B mechanically alloyed precursor 25 Deformation Precursor Thermal Treatment Drawing Ag Tube Bundling Drawing Rolling Cross section Longitudinal Section PIT conductors Preparation of HTSC conductors BiPbSrCaCuO (2223) PIT conductor 26 available in long length moderate performance (Jc < 60kA/cm2) not applicable in magnetic fields at 77 K too expensive (Ag) MgB2 PIT conductor first long length available potential application at ~ 20 K (boiling point of hydrogen) combined with hydrogen technology MgB2 Nb Cu CuNi 600 m long BSCCO tape MgB2 multifilamentary conductor Cross section of BSCCO tape with 61 filaments 13 YBCO coated conductors Advantage: high irreversibility fields at 77 K Challenge: grain boundaries Bi-2223 77K YBCO 6 10 2 J (A/cm ) 5 10 c YBCO coated conductors Application of YBCO for HTSC conductors Y123 4 10 0 4 8 12 16 GB angle (°) • Powder-in-tube technology does not work for YBCO • Long length of highly textured YBCO conductors required 27 Growth of epitaxial YBCO on a textured template: template: coated conductors Preparation of YBCO coated conductors YBCO coated conductors Major processing routes for YBCO coated conductors Rolling Assisted Biaxially Textured Substrates (RABiTS) Ion Beam Assisted Deposition (IBAD) Rolling and Annealing Ion beam Ni, Cu PLD, Sputtering Thermal evaporation CVD,CSD Based on biaxially textured substrates PLD e-beam Sputtering Based on biaxially textured buffer layers 28 14 RABiTS Approach YBCO coated conductors Rolling Assisted Biaxially Textured Substrates (RABiTS (RABiTS)) 29 Rolling Recrystallization Epitaxial Film Deposition Nickel • Cold deformation >95% • Typical 900°C/1h • Pure Ni • Ar/H2-atmosphere • Microalloyed Ni : Ni-0.1at%Mn • Alloyed Ni : Ni-5at%W Ni-7.5at%W Ni-9at%W Ni-9at%V Ni-13at%Cr • Composites : Ni-W/Ni-Cr Ni-W/Ni-W • PLD • E-beam • Sputtering • CVD • CSD (111)-pole figure of Ni-5at%W Tape Processing I YBCO coated conductors Hot rolling 30 Induction furnace Intermediate Ni bars Final tape (up to 100 m) Special 4high mill 15 Tape Processing II YBCO coated conductors Continuous tape annealing Process gas Characterisation Electron backscattering diffraction (EBSD) Exhaust Tape Exhaust Tape Heating zone B Heating zone B Heating zone A Reel Gas Reel, motorized Gas Continuous Tape Annealing „Kikuchi pattern“ Local texture information „Texture maps“ 31 YBCO coated conductors on RABiTS YBCO coated conductors Epitaxial deposition of buffer layers and YBCO Necessary function of buffer layers: • Suppression of Ni diffusion into YBCO (Ni degrades superconductivity) • Suppression of uncontrolled O diffusion to substrate (may lead to cracks and peeling off) • Texture transfer from substrate to superconductor (cube textured YBCO) (111) Ni-5at%W RABiT substrate YBCO (103) CeO2 YSZ Y2O3 32 YBCO coated conductor architecture Ni Cross section of coated conductor YBCO layer Hühne, R. et al., Supercond. Sci. Technol. 20 (2007) 709 16 YBCO coated conductors on RABiTS YBCO coated conductors Pulsed laser deposition - PLD • high quality of layers • flexible method • small substrates (typical 10 x 10 mm²) • vacuum equipment necessary • high costs thermo couple laser plume target substrate heater laser beam ideal for research and development Chemical solution deposition - CSD Starting material as organic compounds dipcoating heat treatment • no vacuum necessary • easily scalable on long length • high yield achievable • large coating areas possible substrate A B C precursor solution ideal for industrial processing 33 Preparation of YBCO coated conductors YBCO coated conductors Major processing routes for YBCO coated conductors Rolling Assisted Biaxially Textured Substrates (RABiTS) Ion Beam Assisted Deposition (IBAD) Rolling and Annealing Ion beam Ni, Cu PLD, Sputtering Thermal evaporation CVD,CSD Based on biaxially textured substrates PLD e-beam Sputtering Based on biaxially textured buffer layers 34 17 Ionenstrahlunterstützte Deposition (IBAD) YBCO coated conductors Principle: Comparison to RABiTS approach Substrate Ionenstrahl all kind of substrates possible smaller grains and sharper textures compared to RABiTS higher Jc extremely fast texturing process for IBAD-MgO or IBAD-TiN (within 10 nm!) PLD Evaporation Sputtering Target complex process smooth (polished) substrates necessary vacuum equipment and on-line control necessary Preparation of textured buffer layers Typical IBAD coated conductor architecture Superpower Inc. (USA) 35 Available in length of > 1 km Ion-beam assisted deposition (IBAD) YSZ, CeO2, Pr6O11, Gd2Zr2O7... MgO, TiN… Cube texture in 10 nm thick IBAD-layers on amorphous substrates 35 in-plane orientation [°FWHM] YBCO coated conductors Materials for the IBAD process: process: IBALD-YSZ, 2,3 Å/s additional epitaxial CeO2 IBALD-YSZ, 1,2 Å/s additional epitaxial CeO2 30 25 Wang et al. APL 71 (1997) 2955 20 15 10 5 divergence of the ion beam Betz (1998) 0 0 1 2 3 4 5 6 YSZ-thickness [µm] Ion beam improves in-plane texture through a growth selection process Slow process Ion beam influences already the nucleation Very fast process 36 18 Optimization of YBCO coated conductors Reduction of ac-losses • improvement of the critical current density Jc in magnetic fields • incorporation of nanosized pinning sites: • non-superconducting particles • growth defects through islands on the substrate • magnetic nanoparticles development of RABiTS with reduced ferromagnetism • hysteretic losses in YBCO due to conductor geometry 6 10 5 10 4 10 3 10 filamentation of conductors MOD-YBCO 1.5 at.% Hf MOD-YBCO 1 at.% Hf MOD-YBCO 0.5 at.% Hf MOD-YBCO 8 7 6 5 4 3 2 1 0 T = 77K BIIc 0.15 mm 4 mm 0 2 4 6 8 10 magnetic field µ0H /T 0 37 • losses due to magnetization change of ferromagnetic substrates 7 10 Pinning Force Density 9 ³ Fp(10 N/m ) critical current density Jc [A/cm²] YBCO coated conductors Artificial pinning centres 2 4 6 magnetic field µ0H /T 8 Engel, S. et al., Appl. Phys. Lett. 90 (2007) 102505 • coupling losses in multilayer systems Summary Summary • HTSC are highly anisotropic, ceramic superconductors • HTSC are potential materials for different applications using liquid nitrogen cooling • Main challenge is to prepare flexible conductors with high critical current densities in higher magnetic fields on long length • Different approaches were developed to realize such conductors: Powder-in-tube technology Coated conductors 38 19