Materials Science and Engineering

advertisement

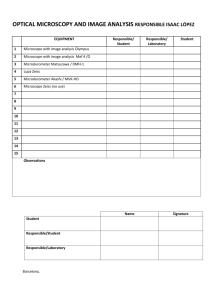

Materials Science and Engineering The Clemson University School of Materials Science and Engineering (MSE) has six research centers in five different divisions dedicated to the development of new polymers, fibers, ceramics, composites and metals. These are the Clemson Apparel Research (CAR), the Center for Optical and Materials Science Engineering and Technology (COMSET) ‐ located in Advanced Materials Research Laboratory (AMRL), the Clemson Conservation Center at the Warren Lasch Laboratory, the Center for Advanced Engineering Fibers & Films (CAEFF), the Electron Microscopy Facility ‐ located in Advanced Materials Research Laboratory (AMRL) and the Clemson University International Center for Automotive Research (CU ‐ ICAR). The main office for the School of Materials Science and Engineering is located in 161 Sirrine Hall. Offices for faculty, staff, and teaching assistants are located in both Sirrine and Olin Halls. Several faculties have offices in the Advanced Materials Research Laboratory located in Clemson University Research Park. The CME (inorganic materials concentration of the MS&E) program is primarily housed in Olin Hall with a few classes being taught in Sirrine Hall and select laboratories off campus at the National Brick Research Center in Pendleton. The polymeric materials concentration of the MS&E program will be primarily housed in Sirrine Hall with a few lecture classes being taught in Olin Hall. Classrooms are also available campus‐wide on an as needed basis. Olin Hall contains two classrooms scheduled and maintained by the University. Both are adequate for present needs. Olin 200 is a 107‐seat lecture hall currently equipped as a ―smart classroom‖ with a computer podium, projector, video tape player and video network connections. The second classroom, Olin 203, is a 20‐seat smart/distance classroom (upgraded in 2010) with a computer podium and distance capability. In 2000 Olin Hall underwent the modernization of electrical and HVAC facilities, with completion in the late spring of 2000. Also a complete fume hood system was installed. Olin Hall contains six undergraduate instructional laboratories and a computer laboratory. The six undergraduate laboratories include an optical microscope, microscopy sample preparation area, mechanical property testing laboratory, materials fabrication areas and physical property measurement laboratory. The computing laboratory is equipped with four PC workstations. Software includes both standard word processing and data management programs as well as programs specifically required to support the undergraduate program, e.g., Thermo‐Calc. This lab is open for student use during the day or after hours by arrangement. All PCs accessible are connected to the campus network. Students also have access to computing labs operated by CNS and DCIT and can utilize their own laptop computers on the Clemson network. Sirrine Hall contains a single 30‐seat classroom utilized by the CME (inorganic materials concentration of the MS&E) program. This classroom is a traditional classroom which is also equipped with a projector that can be run off a laptop computer. A newly renovated smart classroom was activated in Sirrine Hall (room 260) in Fall 2005. Sirrine Hall contains six undergraduate instructional laboratories. The six undergraduate laboratories include an optical microscope/ microscopy sample preparation area, physical property testing laboratory and analytical testing laboratory. The microscopy laboratory contains four microscopes equipped with Image Analyses software required to support the undergraduate programs. The physical property testing laboratory contains two Instron Tensile Testers with Bluehill 2 software along with numerous other materials testing equipment required for the collection of data supporting undergraduate programs. The analytical testing laboratory contains equipment for analyzing intrinsic material properties, instruments include FTIR, DSC, TGA, TMA and DMA with computerized data collection essential to the support of undergraduate programs. The microscopy and physical property testing laboratories are open during the day and after hours by arrangement for student usage. The School of Materials Science and Engineering has also made use, on a limited basis, of the National Brick Research Center located approximately five miles from the main campus. Future plans are to increase the use of the National Brick Research Center facilities for manufacturing purposes. Ceramic and Materials Engineering (MS&E Inorganic Materials Concentration) Program ‐ Olin and Sirrine Hall Lab Facilities Physical Facility, Building and Room Number Olin Large Bay Area Powder Processing Lab. Olin 14 Condition Adequate Adequate Area (sq.ft) 2793 572 Kiln Room, Basement Olin Fine Particle Lab., Olin 102 Thermal Analysis Lab, Olin 100 Microscope Lab, Olin 208 Polishing Lab, Olin 212 Properties Lab, Olin 210 National Brick Research Center, Pendleton Computer Lab, Olin 204 Polymer Lab, Sirrine 64 Adequate Adequate Adequate Good Adequate Adequate Excellent Adequate Adequate 950 374 330 300 418 Clemson Apparel Research Center The Clemson Apparel Research Center (CAR) is a premier national resource for high‐ performance textiles and related materials research and applications. CAR provides services in consulting manufacturing and design through its 6,000 square foot model apparel plant that demonstrates more than 2 million in state‐of‐the‐art technology, including design, cutting, stitching, and finishing equipment. Two technologies have been created within the research center; BalancedFlow™ , a supply chain execution that maximize profits by multiplying revenue and minimizing costs across the entire supply chain, and Duraseal™, a unique method for joining two or more substrates with a seam, which can be used with chemical or biological barrier products. The CAR also has a staff of qualified engineers to address manufacturing problems (e.g. efficient plant layouts) and professors in the COES Depts. of Engineering, Computer Science, and Mathematical Science strengthen the level of expertise. CAR also designs patterns for both apparel and non‐apparel items, using the Gerber Accumark CAD system and can use Lectra Systems upon request. Clients include the U.S. government, and the U.S. Military. CAR staff frequently work on proprietary projects are cleared for classified work. CAR also operates a 6,000 square foot model apparel plant with ultramodern design, cutting, stitching, and finishing equipment. Apparel manufacturers use CAR to evaluate the most advanced apparel production equipment on the market as it actually produces garments. CAR also uses AMCIA (Apparel Manufacturing Capital Investment Advisor) to help assist apparel companies appraise technology from an investment standpoint. The plant has 12 sewing operators that demonstrate new manufacturing equipment and innovative manufacturing concepts while producing 900‐military and commercial shirts per week. CAR undertakes many annual research projects to create technologies for the sewn‐products and textile industries, including stitchless technology for barrier fabrics that can reduce joining costs for other fabrics. Clemson University Research Initiative (CURI) The Clemson Conservation Center (CCC) specializes in the conservation of archeological finds, determinations of materials, and other fundamental and advanced conservation techniques. Currently housed in the former Charleston Naval Complex, The Clemson Conservation Center is the perfect place for the restoration of marine type artifacts, including the H.L. Hunley and two full size cannons from the USS Alabama. This facility is considered to be perhaps one of the finest in the world. The 82 acre Clemson University Restoration Institute is one of the principal supporting materials laboratory for all of Clemson’s low‐country programs. The CCC has the following equipment Breuckmann optoTOP‐HE White Light Scanner – Used to develop new approaches for utilizing digital and scanning technologies to study, analyze and reconstruct objects or sites. This scanner uses structured‐light scanning technology for surface scanning and 3D topography, resulting in highly accurate surface measurements. Hitachi 3700N Scanning Electron Microscope ‐ The Hitachi 3700N, designed for conventional and variable pressure microscopy with ultra large chamber, allows observation of most samples in their natural state, or wet condition, without the need of metal coating. This Hitachi SEM has an Oxford INCAx‐act EDS, and an INCAWave 500i WDS which provide accurate qualitative and quantitative elemental microanalysis. It also includes secondary electron detector (SE), backscattered electron detector (BSE) and environmental secondary electron detector (ESED). Bruker Optics SENTERRA Raman Microscope – Used for analyzing both organic and inorganic materials, the Bruker Optics SENTERRA dispersive Raman microscope equipped with 532nm, 633nm and 785nm lasers, 20X and 50X bright field objectives, 10X, 20X, 50X long working distance and 60X water immersion objectives and computer controlled x,y,z mapping stage. Bruker Optics HYPERION FT‐IR (Infared) Microscope ‐ Used for infrared and micro‐ infrared spectral analysis, this IR microscope has a Bruker Optics TENSOR 27 FT‐IR spectrometer with a Pike ʺMIRacleʺ single reflection diamond ATR accessory. It also has Ge ATR and 15X objectives, a computer controlled x‐y mapping stage, visible and IR polarizers, and a fluorescence accessory. This $10.3 million dollar center serves as a principal supporting materials laboratory encompassing a building, tank room, and laboratory. The lab is equipped with an X‐ray machine with imaging computer and film printer, research reactors, Leica microscopes, and custom built freezer unit. The tank room, which current houses the H.L. Hunley submarine, has large 50 ton cranes (with rails), a 50,000 gallon tank (location of the submarine with truss) with a viewing mezzanine, and areas for studies on other artifacts for conservation. This tank room supports both marine and conservation studies. Current conservation projects involving the H.L. Hunley and Magnolia Gardens are being done developing a restoration process to reduce the timeline of conserving an artifact from months to days, which have the potential to protect ships and metal structures exposed to saltwater. Clemson University Electron Microscope Facility The Clemson University Electron Microscope Facility located in the new $21MM Advanced Materials Research Laboratory (AMRL) in the Clemson Research Park has eight scopes representing the latest in state‐of‐the‐art microscopy technology. This multi‐user teaching facility has clients from automotive, pharmaceutical, textile, electronics, environmental and medical industries. The economical cost, wide range of capabilities and minimum wait time makes the facility very attractive to area researchers. The facility has a Director, three research specialists, and a senior associate that are available to assist clients as needed. Available equipment includes gold, platinum, chromium and carbon coaters, RMC Powertome X with cryo and a Reichert‐Jung Ultracut E Microtomes, an RMC Glass Knife Maker, Fischione Model 170 Ultrasonic Disk Cutter, a Fischione Model 150 Dimpling Grinder, a Fischione model 1020 Plasma Cleaner, a Buehler SamplMet 2 Rough Cut Saw, a Buehler Isomet 1000 Wafering Saw, and a Buehler Ecomet 3 w/Automet 2 Power Head Polisher. Account holders at the Lab may also access images from home; USB flash drives are required for storing EDS WDS word files. Unique images are on display around the E.M. Facility, professionally colorized and framed, and “signed” by the author. The Electron Microscope Facility has the following scopes: Transmission Electron Microscopes A TEM 9500 with 300kv high magnification TEM and is designed for atomic resolution. This TEM 9500 has 0.18nm point‐to‐point lattice resolution and a 2K by 2K Gatan camera. A STEM‐Hitachi HD2000‐200kV that offers 200kv high resolution field emission microscopy and is specifically designed for material science applications. It is equipped with an Oxford INCA Energy 200 EDS attachment. This STEM has 0.204nm point‐to‐point resolution in the brightfield mode and 0.5nm in the secondary mode. A TEM‐Hitachi H7600T‐120kV with LaB6 capability for a wide variety of material science/biological applications where selective kv is required. It is equipped with an Oxford INCA Energy 200 EDS, double tilt stage, multi‐specimen holder, tomography, STEM, and cryo attachment. It has 0.204nm Point to point resolution, and is equipped with a cryo stage and Auto Tomography. Scanning Electron Microscopes A FE (Field Emission) SEM‐ Hitachi S4800, designed for high resolution microscopy. It is equipped with an Oxford INCA Energy 200 EDS and a GW Electronics Centaurus backscatter detector. It has 1.8nm resolution at 1kV, and has EDX. A Variable Pressure SEM 3400 designed for conventional and variable pressure microscopy. It is equipped with an Oxford INCA EDS, WDS, EBSD, and built‐in four quadrant solid‐ state backscatter detector. It also has SEM imaging capability in variable pressure. It has 3.0nm resolution at 30 kV, equipped with EDX, WDX and EBSD. A FE (Field Emission) Variable Pressure SEM, Hitachi SU6600 designed for high resolution work in the variable pressure mode as well as standard FESEM mode. Equipped with EDX and the HKL electron backscatter diffraction system, EBSD. The TM3000 tabletop SEM for conventional imaging. Excellent for low magnification work. It is equipped with EDX. A Focused Ion Beam (FIB) Hitachi FB2000A‐30kV Ga source, used for thin sample TEM and STEM preparation. Extensive sample preparation equipment: o o o o o o o o o Coaters: gold, platinum, chromium and carbon Microtome: RMC Powertome X with cryo and a Reichert‐Jung Ultracut E Glass Knife Maker: RMC Ultrasonic Disk Cutter: Fischione model 170 Dimpling Grinder: Fischione model 150 Plasma Cleaner: Fischione model 1020 Rough Cut Saw: Buehler SamplMet 2 Wafering Saw: Buehler Isomet 1000 Polisher: Buehler Ecomet 3 w/Automet 2 power head Equipment and Facilities (Sirrine Hall) The Clemson Material Sciences Department also contains 11 laboratories, comprised of the Weaving Laboratory and Nonwoven Laboratory, the Dyeing, Finishing & Printing Laboratory, the Clemson Apparel Research Facility, a Composites Fabrication Facility, physical testing and fiber physics laboratories, an electrical/electronic fiber and fabric properties laboratory, an extrusion and rheology facility, an analytical laboratory, and an Analytical Laboratories Advanced Metallic and Composites Group. Graduate students from the School also have access to the Universityʹs excellent electron microscopy (scanning, transmission and Auger microanalysis) laboratory, a newly installed X‐ray diffractometer in Ceramic Engineering, stereo lithography in Bioengineering, and hydraulic mechanical testing for fatigue analysis in Mechanical Engineering. Clemson University also provides its graduate students with universal Internet access and outstanding mainframe, mini and micro‐computational support. Weaving Laboratory The Weaving Lab contains a Pignone Loom with Staubli Electronic Jacquard 1.9 Meters in length, with 2688 Hooks; a Picanol OMNI‐A Air Jet Loom 70ʺ, with Cam; a AVL 24 Inch Industrial Dobby Loom; a Herzog Braider with 2‐16 Spool Discs; A Herzog Winder with a 2 Spool w/Creel. The New Nonwoven Lab contains a CMC Rando ‐ Opener/Cleaner, a Bamatic Chute Feeder, a Bamatic Card, a Bamatic Cross Lapper, and an Automatex Needle Puncher. The Web Formation lab contains a 12” Rando Webber, a 20” Proctor and Schwartz Roll‐Top Card, and an EVAC Vacuum System, The Web Finishing Lab contains a 20ʺ Aztec Hot‐Air Thru Oven 20ʺ; a Benz Thermal Bonding Calendar; a James Hunter 9ʺ Pin‐Sonic Bonder for fusing thermoplastic binders; a 12ʺ Fiber Locker Needle Punch; and a 12ʺ Hydro‐Entanglement Water Jet System. The Dyeing, Finishing & Printing Laboratory contains two (2) Despatch Ovens, an Ernst Benz Oven, a Rotary Washer, a Centrifigal Extractor, a Speed Queen Industrial Dryer, a Padder and Ernz Benz oven for industrial comparisons of latex trials, a Stork Roller Printer, a Werner Mathis Steamer, a Paddle Wheel Dyer, two Altas Launderometers, a Flat Bed Screen Printer, an Ahiba Dyer, and an Atlas Fadeometer with a carbon arc lamp. Composites Fabrication Laboratory contains a Carver 18x18ʺ 60 Ton, 350 C, Hydraulic Press. Physical Evaluation Facility–Room 270/272–The PEF, which serves the Graduate Students, and Faculty of the School of Materials Science and Engineering, is also available to other Departments in the COES and the University. The Laboratory uses various published ʺStandardsʺ such as American Society Testing & Materials (ASTM), Federal Test Methods (FTM), American Association of Textile Colorists & Chemists (AATCC ) as well as ʺStandardsʺ written by individuals and companies to accomplish the testing required. This assures compatibility and repeatability between tests and other facilities. The PEF has the following equipment. Fiber and Yarn Property Characterization Zellweger Uster HVI 900 Zellweger Uster AFIS Zellweger Uster, Uster Tester III Zellweger Uster, Uster Tester IV Techno Statimat II M Lawson Hemphill CTT Yarn Tester Lawson Hemphill EIB Yarn Tester Fiber/Yarns/Fabric Characterization Instron 1125R/5500 Instron 5582 Textest 3000 Hydrostatic Head Tester Textest 3300 Air Permeability Tester Textest 3700 Digital Elmendorf Pilling, Abrasion, Burst, Drape, Flammability Optical Microscopy and Image Analysis Systems (2) Aus Jena JENAPOL U INTERPHAKO Polarizing Mach Zehnder Interference Research Microscope (Birefringence) Leitz Labrolux R/T w/lightfield and darkfield Fiber Microtomes Beuhler Two Head Polisher/Grinder & Isomet 1000 Saw for sample Preparation Image Analysis Systems ( Color ) Sony Video Printer Sony Digital Camera Model 90 with Martin Microscope Camera to Microscope Adapter Sony Super VHS Recorder with Camera and Lens Color Measurement MacBeth ColorEye 3000 Spectrophotometer Xrite SP78 Spectrophotometer The Fiber Physics Laboratory is equipped with a computer‐controlled single filament torsional modulus instrument, a breaking twist angle tester, a Keithley, Inc., System for electrical, conductivity measurements, electrostatic voltmeters, a thermal conductivity testing apparatus, a single fiber accoustic emission failure analyzer, a sonic modulus analyzer, a Keithly 6517A Electrometer/High Resistance Meter, and a Keithly 182 Sensitive Digital Voltmeter. The Electrical/Electronic Fiber and Fabric Properties Laboratory is equipped with a Hewlett Packard 8757XB Microwave Scaler Network Analyzer 100MHz to 50GHz, a Hewlett Packard Scaler Analyzer (S parameter test), a Questek 2010 Excimer Laser, an Alessi Four Point Probe, a Keithly 228A Voltage/Current Source, a Keithly 220 Current Source, a Keithly 197A Microvolt Digital Multimeter, and Keithly 2000 and 2001 Digital Multimeters. The Extrusion and Rheology Laboratory has a Hills, Inc. Pilot Scale Fiber Extruder, 1ʺ, 1800 m/min, a Barmag SW7 High Speed Winder, a Instron Capillary Rheometer, a Haake Rheocord 90 Rheometer, a Brookfield DV‐III Rheometer, a Lab Scale Wet Spin Line, an Instron 4502 with Model 3210 Rheometer, and a Headway Research, Inc. PM 101DT‐R790 Spin Coater. The Analytical Laboratories have equipment for conducting work in the following areas. Chemical Analysis, Separation Science: Equipped with a Dionex Liquid Chromatograph with GP50 Pump & AD25 Absorbance Detector; a Waters Breeze Gel Permeation Chromatograph with Waters 2487 UV/Vis, Waters 2414 DRI, Waters 717 Auto‐Sampler & PolymerLabs PL‐ELS 2000; and a Selerity Series 4000 SFC. Spectroscopy: a Nicolet Magna 550 with NicPlan FT‐IR Microscope and Mapping Stage, a Thermo 6700 FTIR with Continuum FTIR Microscope, a Shimadzu 3101‐PC UV‐Vis‐ NIR Spectrometer, an FT‐NMR Spectrometer, and a Thermo Finnigan Trace GC/MS. Chemical Instrumentation: a Cahn Dynamic Contact Angle Analyzer, a SensaDyne Bubble Tensiometer, a Kruss DSA 10 Contact Angle Analyzer, a Suprex PrepMaster Supercritical Fluid Extractor, a Dionex ASE 200 Accelerated Solvent Extractor, a Wyatt Technology Dawn DSP Laser Light Scattering: 18 angle Ar+, and an Optilab DSP Differential Refractometer. Thermal Analysis: a 2950 Hi‐Res Thermogravimetric Analyzer, a 2920 Differential Scanning Calorimeter, a TA Instruments Q1000 DSC, Q5000 TGA, and Q800 DMA, a Seiko Instruments SSC 5300 Thermal Analysis System, a Seiko DMS 210 Dynamic Thermal Mechanical Analyzer, a Seiko TMA/SS 350 Thermal Mechanical Analyzer, a Solomat TSC/RMA Relaxation Spectrometer, and a Parr 1455 Solution Calorimeter. AMRL: a Waters Gel Permeation Chromatograph: 815 HPLC Pump, Heated Columns, 410 DRI, 486 Abs. Det.; a Viscotek T50A Differential Viscometer; a Bio‐Analytical Systems 100B Electrochemical Analyzer; and a Jupiter Intrument Co. Membrane Osmometer Model 231. The Advanced Metallic and Composites Facilities have equipment for conducting research in the following areas. Materials Processing: a planar flow caster, an Ajax induction melting system, two Centorr arc melters, an Inert atmosphere melt spinner, a Lombard 150 ton vertical extrusion/forging press, a Stanat 2/4/6 high instrumented rolling mill, an equal channel angular extruder, a Solidica Form‐ation ultrasonic consolidation system, two attritor mills, three powder blenders, shaker sieves, a spec’s mill, a high temperature (2000C) inert atmosphere furnace, a single crystal puller, six lindberg tube furnaces, five Lindberg box furnaces, six thermcraft salt balts, two low temperature oil baths, a Huppert recirculating air furnace, a Marshall vertical quench furnace, a high temperature(1650C) inert atmosphere quench furnace, a high pressure infiltration system, a low pressure infiltration system, and a Quartz Encapsulation system Material Characterization: a Scintag XDS 2000 x‐ray diffractometer, a Nikon inverted optical microscope, a Netszch differential calorimeter (‐110C to 1600C), two in‐situ, inert atmosphere high temperature resistivity systems, an Eddy current apparatus, a dynamic modulus apparatus with assorted transducers, twelve high temperature creep machines, two MTS/Instron closed loop servohydraulic machines, Instron/MTI screw driven test machines, three RR Moore rotating beam fatigue machines, an RI Thermal fatigue apparatus, three automated reciprocating sliding wear apparatus, two pin‐on‐disk wear apparatus, a high velocity gas gun, and an instrumented SATEC impact machine Metallographic Equipment: a Struers Cut‐off machine, a Buehler high speed diamond cut‐off machine, a South bay abrasive wire saw, a Buehler hot press, surface grinder, four Buehler grinders, six Struers automatic polishers, three Vibramet automatic polishers, two Buehler electropolishers, a fatigue/tensile sample electropolisherm, a South bay core grinder, a high definition scanner, two Gatan ion millers, a Gatan dimple grinder, a Gatan ultrasonic disk cutter, and a Fischione TEM jet polisher. The lab also has software licenses for ABAQUS, Thermo‐Calc, Carine Diffract, Adobe Photoshop, Image Pro and Fovea Pro.