REPLENISHING THE FLIGHT-CREW OXYGEN SYSTEM 1

advertisement

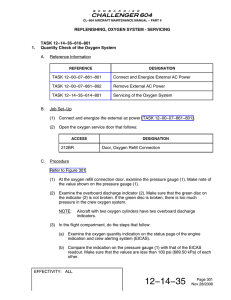

REPLENISHING THE FLIGHT-CREW OXYGEN SYSTEM 1. Quantity Check of the Flight-Crew Oxygen System A. Reference Information 1. Servicing of the Flight-Crew Oxygen System 2. Connect Electrical Power to the Aircraft 3. Remove the Electrical Power from the Aircraft 4. Oxygen System Safety Precautions B. Job Set-Up (1)Obey all the oxygen-system safety precautions. (2)Connect electrical power to the aircraft. (3)Open the oxygen fill-and-indicator door (121 CL). C. Procedure Refer to Figure 301. (1)Do the quantity check of the flight-crew oxygen system as follows: (a)Examine the oxygen pressure indication on the ground service-panel pressure-gauge (1). (b)Record the value shown on the pressure gauge. (c)Record the value of the ambient temperature. (d)Make sure that the green disk (2) on the overboard discharge indicator is not broken. (2)In the flight compartment, on the ELECTRICAL control panel, set the BATT MASTER switch to ON. (3)In the flight compartment, on the EMS CDU, do the steps that follow: (a)Go to the CIRCUIT BREAKER -STATUS page. (b)Make sure that the circuit breaker that follows is not set to LOCK, OUT, or TRIP: CIRCUIT NAME OXYGEN CIRCUIT BREAKER NAME OXYGEN BUS NAME BATT (4)On the engine indication and crew alerting system (EICAS), make sure of the conditions that follow: (a)Make sure that the amber caution message OXYGEN LO CITY does not show. (b)Make sure the oxygen pressure indication shows 97% to 100%. NOTE: Because the pressure transducer is temperature-compensated, the EICAS indication can be different from the pressure gauge indication (if the external ambient temperature is not 21 °C (70 °F)). Make sure that the pressure in the flight-crew oxygen system is to the correct level. Refer to the table that follows: AMBIENT TEMPERATURE FULLY PRESSURIZED INDICATION 1p 1990 psi (13720.65 kPa) 19ps 1900 psi (13100.12 kPa) 91sp 1805 psi (12445.11 kPa) 18ps 1710 psi (11790.10 kPa) 17ps 1620 psi (11169.57 kPa) 16ps 1530 psi (10549.04 kPa) 15ps 1435 psi (9894.03 kPa) 43sp 1340 psi (9239.03 kPa) 4s (6)If the pressure in the oxygen system is not at the correct level, do the servicing of the flight-crew oxygen system. (7) In the flight compartment, on the ELECTRICAL control panel, set the BATT MASTER switch to OFF. (8)Remove the electrical power from the aircraft. 100 °F (37.7 °C) 80 °F (26.6 °C) 60 °F (15.5 °C) 40 °F (4.4 °C) 20 °F (-6.6 °C) 0 °F (-17.8 °C) -20 °F (-28.9 °C) 1-40 °F (-40 °C) D. Close Out (1)Remove all tools, equipment, and unwanted materials from the work area. (2)Close the oxygen fill-and-indicator door (121 CL). 2. Servicing of the Flight-Crew Oxygen System A. Reference Information REFERENCE Connect Electrical Power to the Aircraft Remove the Electrical Power from the Aircraft Oxygen System Safety Precautions Removal of the Forward Equipment-Compartment Access-Panels Installation of the Forward Equipment Compartment Access-Panels B. Tools and Equipment REFERENCE Oxygen Service Cart Adapter -Oxygen System NOTE: For ground support equipment (GSE), refer to the Illustrated Tool and Equipment Manual (ITEM). C. Job Set-Up (1) Obey all the oxygen-system safety precautions (2) Open the oxygen fill-and-indicator door (121 CL). (3) Remove the forward equipment-compartment access-panels. D. Procedure WARNING: DO NOT LET OIL, GREASE, OR SOLVENTS GET ON YOUR HANDS, CLOTHING, OR THE EQUIPMENT USED TO DO WORK ON THE OXYGEN SYSTEM. IF OXYGEN TOUCHES OIL, GREASE, OR SOLVENTS, THEY CAN START TO BURN. CAUTION: MAKE SURE THAT THE PRESSURE OF AN OXYGEN CYLINDER IS NOT LESS THAN 50 PSI (340 KPA). IF THE PRESSURE IS LESS THAN 50 PSI (340 KPA), CONTAMINATION CAN GO INTO THE OXYGEN CYLINDER. IF THIS OCCURS, YOU MUST BLEED THE OXYGEN SYSTEM (AFTER YOU REMOVE THE OXYGEN CYLINDER) AND DO TESTS FOR PURITY ON THE SYSTEM AND THE CYLINDER. (1) Do the servicing of the oxygen system as follows: (a)Make sure the oxygen storage cylinder and regulator assembly levers are in the ON position. (b)Make sure the crew oxygen-mask regulators are set to N. (c)Remove the dust cap from the oxygen filler valve. (d)Connect the oxygen servicing cart fitting to the oxygen filler valve. (e)Slowly open the oxygen servicing-cart supply-valve and fill the oxygen storage cylinders to the correct pressure (refer to the servicing placard adjacent to the oxygen filler valve). NOTE: Make sure you do not fill at a rate of more than 200 psi (1 378.96 kPa) per minute. (f) Close the oxygen servicing-cart supply-valve. (g)Make sure the temperature is stable for a minimum of 10 minutes. (h)Make sure the oxygen pressure indication on the oxygen storage cylinder and regulator assembly is at the correct pressure (refer to the servicing placard adjacent to the oxygen filler valve). (i) Make sure the oxygen pressure indication on the ground-servicing-panel pressure gauge is at the correct pressure (refer to the servicing placard adjacent to the oxygen filler valve). (j) Carefully loosen and disconnect the oxygen servicing-cart supply connection. WARNING: MAKE SURE THAT NO CONTAMINATION GETS INTO THE OXYGEN SYSTEM. PUT THE PROTECTIVE COVER ON THE FILLER VALVE IMMEDIATELY AFTER YOU DO THE REPLENISHING OF THE OXYGEN SYSTEM. CONTAMINATION IN THE OXYGEN SYSTEM CAN CAUSE INJURY TO PERSONS AND DAMAGE TO EQUIPMENT. (k)Immediately install the dust cap on the oxygen filler valve. (l) Connect electrical power to the aircraft. (m) On the engine indicating and crew alerting system (EICAS), make sure of the conditions that follow: 1 The caution indication OXYGEN LO QTY does not show. 2 The oxygen pressure indication shows 97% to 100%. NOTE: Because the pressure transducer is temperature-compensated, the EICAS indication can be different from the pressure gauge indication (if the external ambient temperature is not 21 °C (70 °F)). (n)Remove the electrical power from the aircraft. E. Close Out (1)Remove all tools, equipment, and unwanted materials from the work area. (2)Close the oxygen fill-and-indicator door (121 CL). (3)Install the forward equipment-compartment access-panels.