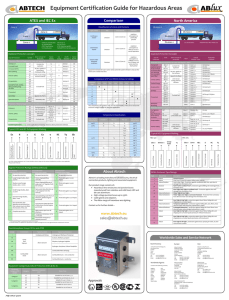

ATEX Certification Definitions

advertisement

ATEX Certification Definitions Typical IEC EPL General requirements Typical Zone(s) EN/IEC Standard 0,1,2 60079-0 Is equipment Ex i concept? Gb Ga Ga 1,2 0,1,2 0,1,2 60079-28 60079-28 60079-28 Protected Optical Radiation Optical System with Interlock Intrinsically Safe Optical Radiation Increased safety Type ‘n’ (non sparking) e nA Gb Gc 1,2 2 60079-7 60079-15 No arcs, sparks or hot surfaces. Enclosure IP54 or better Flameproof / Explosion-Proof Type ‘n’ (enclosed break) d nC Gb Gc 1,2 2 60079-1 60079-15 Contain the explosion, quench the flame Quartz/sand filled q Gb 1,2 60079-5 Quench the flame Intrinsic safety Intrinsic safety Intrinsic safety ia ib ic Ga Gb Gc 0,1,2 1,2 2 60079-11 60079-11 60079-11 Limit the energy of sparks and surface temperatures Pressurised Pressurised Pressurised px py pz Gb Gb Gc 1,2 1,2 2 60079-2 60079-2 60079-2 Keep the flammable gas out Type ‘n’ (sealing & hermetic sealing) Type ‘n’ (restricted breathing) nC nR Gc Gc 2 2 60079-15 Keep the flammable gas out Encapsulation Encapsulation Encapsulation ma mb mc Ga Gb Gc 0,1,2 1,2 2 60079-18 60079-18 60079-18 Oil immersion o Gb 1,2 Gas EU Explosive Atmosphere Symbol ATEX Coding Enclosure Intrinsic safety Encapsulation Pressurised Typical IEC EPL ta tb tc ia ib ic ma mb mc Da Db Dc pD Db Dc Typical Zone(s) 20,21,22 20,21,22 20,21,22 60079-6 21,22,22 Basic concept of protection 60079-31 Standard protection for dusts, rugged tight enclosure 60079-11 Similar to t, but with some relaxations if circuit inside is intrinsically safe 61241-4 Dust 0 20 1 21 2 22 ATEX Certificate No. ---- Equipment Category Equipment Group M1 I 1 Very high protection 2 High protection 3 Normal protection II 2 GD Surface No Is area zoned? Gas/Dust Groups Protection Concepts EN/IEC Standard General - - 0,1,2 20,21,22 13463-1 Low potential energy Flow restricted enclosure Flameproof / Explosion-proof enclosure fr d - 2,22 1,2,21,22 13463-2 13463-3 Relies on tight seals, closely matched joints and tough enclosures to restrict the breathing of the enclosure Constructional safety c - 0,1,2 20,21,22 13463-5 Ignition hazards eliminated by good engineering methods Control of ignition sources b - 0,1,2 20,21,22 13463-6 Control equipment fitted to detect malfunctions Pressurisation p - 1,2 21,22 60079-2 61241-4 Enclosure is purged and pressurised to prevent ignition sources from arising 0,1,2 20,21,22 13463-8 Enclosure uses liquid to prevent contact with explosive atmosphere Yes Yes Use non-certified cable glands Refer to Ex d cable selector chart Ex e concept Use a barrier gland DO NOT OPEN WHEN AN EXPLOSIVE GAS ATMOSPHERE IS PRESENT Yes Gas Coding Dust Coding Mining Coding Ingress Protection Gas Zones Dust Groups Zone Ga 0 Gb 1 Gc 2 Da 20 2nd Numerical Protection against Liquid Db 21 Dc 22 Ingress Protection 1st Numerical Protection against Solid Bodies 0 No protection 0 No protection Ma Energised* 1 Objects > 50mm 1 Vertically dripping water Mb De-energised* 2 Objects > 12mm 2 Drops of liquid (75° to 90°) 3 Objects > 2.5mm 3 Sprayed water G = Gas D = Dust M = Mining *In presence of explosive atmosphere 4 Objects > 1mm 4 Splashed water 5 Dust protected 5 Water jets 6 Heavy seas Temperature Class Gas Group Gas Example Dust Group Dust Example I Methane (mining only) IIIA Combustible flyings IIA Propane IIIB Non-conductive dust 7 Effects of immersion IIB Ethylene IIIC Conductive dust 8 Indefinite immersion IIC Hydrogen 6Dust-tight T Class Maximum Surface Temperature T1 450°C T2 300°C T3 200°C T4 135°C T5 100°C T6 85°C Note: For Group I (CENELEC/IEC) applications, electrical apparatus has fixed temperature imits i.e., 150°C and 450°C www.extronics.com Wireless Vision Engineering Tracking Does this enclosure contain an internal source of ignition? 1 Dalton Way, Midpoint 18, Middlewich, Cheshire CW10 0HU. United Kingdom Tel +44 (0)845 277 5000 Fax +44 (0)845 277 4000 Email info@extronics.com Use certified cable glands No *refer to note 3 No Is the area of installation of Zone 1? No Use a suitable flameproof cable gland with a sealing ring. (Gland with elastomeric seals) No Definitions Dust IEC 60079-10 0 IEC 60079-10 1 21 A place in which an explosive atmosphere is likely to occur in normal operation occasionally (10≤ x <1000) 2 22 A place in which an explosive atmosphere is not likely to occur in normal operation, but if it does only occurs for short periods (10>x) 20 Basic concept of protection Level *refer to note 2 Brass Zoning Definitions IP66 Ambient Range -20°C to 40°C unless stated on label Ex n* or N concept Plastic Is the volume of enclosure greater than 2 dm3? Yes Ex e concept Gland type Yes DO NOT OPEN WHILE ENERGISED Zone 2 No Use non-certified cable glands Does the hazardous gas require IIC apparatus? Yes 1 Dalton Way, Midpoint 18, Middlewich, Cheshire CW10 0HU. United Kingdom Tel +44 (0)845 277 5000 Fax +44 (0)845 277 4000 Email info@extronics.com Web www.extronics.com Notified Body Identification No Yes Date: 10/02/2015 Serial No.: EXT12345XXX Ex d IIC T6 Gb Ex tD IIIC T100°C Db I M2 Ex d I Mb -20°C ≤ Ta ≤ + 60°C Zone 1? No Note 1: Non certified cable glands may be used provided that they maintain the minimum IP rating on the certified equipment of IP54 for outdoors and IP20 for indoor equipment. Note 2: Non certified cable glands may be used provided they meet the requirements of EN60079-0 and EN60079-7 or EN60079-15. Note 3: Internal sources of ignition include sparks or equipment temperatures occurring in normal operation which can cause ignition. An enclosure containing terminals only or an indirect entry enclosure is considered not to constitute an internal source of ignition. Equipment Protection Level Equipment Protection Level Typical Zone(s) Gas Groups Serial No. and Year of Manufacture Temperature Class Is equipment Ex d concept? No *refer to note 1 Protection by pressurisation of enclosure Typical IEC EPL - Mining *In presence of explosive atmosphere Baseefa 12 ATEX 1234 x IECEx BAS 12 1234 X 0518 Protection by encapsulation of incendive parts Symbol k II De-energised* Protection Concepts - Non-electrical Liquid immersion Energised M2 iPRODUCT100 Keep the flammable gas out EN/IEC Standard 60079-18 Product Identification Keep flammable gas out Protection Concepts - Dust (electrical) Symbol Yes Basic concept of protection Op pr Op sh Op is Optical Radiation START ATEX Coding Protection Concepts - Electrical Symbol Gland Selection A place in which an explosive atmosphere is continually present Ex Environment Example of hazardous area zones Petrol Station Forecourt Zone 0 Zone 1 Zone 2 Fuel Storage Tank Fuel Storage Tank Radio Frequency Sources The threshold power of radio frequency (9kHz to 60GHz) for continuous transmissions and for pulsed transmissions whose pulse durations exceed the thermal initiation time shall not exceed the values shown in Table 4. Programmable or software control intended for setting by the user shall not be permitted. For pulsed radar and other transmissions where the pulses are short compared with the thermal initiation time, the threshold energy values Zth shall not exceed those given in Table 5. Table 4 from EN 60079-0:2012 Radio Frequency Power Thresholds Table 5 from EN 60079-0:2012 Radio-frequency Energy Thresholds Threshold Power (W) Thermal Initiation Time (averaging period) (µS) Group I 6.0 200 Group I 1500 Group IIA 6.0 100 Group IIA 950 Group IIB 3.5 80 Group IIB 250 Group IIC 2.0 20 Group IIC 50 Group III 6.0 200 Group III 1500 Equipment for Equipment for Threshold Energy Zth (µJ)