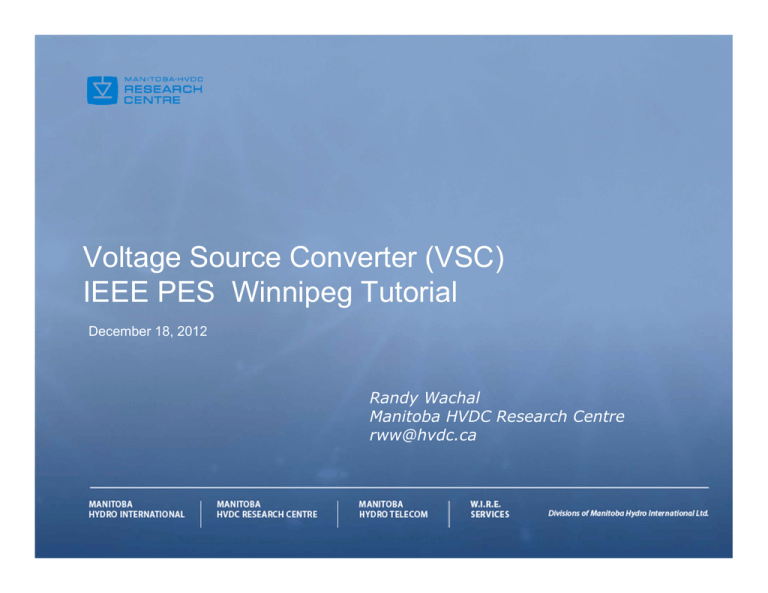

Voltage Source Converter (VSC) IEEE PES Winnipeg Tutorial

advertisement

Voltage Source Converter (VSC) IEEE PES Winnipeg Tutorial December 18, 2012 Randy Wachal Manitoba HVDC Research Centre rww@hvdc.ca Acknowledgements: NSERC Power System Simulation Chair program at University of Manitoba .. MHRC Staff Dr. Farid Mosallat and Juan Carlos Garcia Cigre DC Grid Working Groups B4-55, 56 57 58 59 and 60 .. ABB Siemens and Alstom Grid VSC Tutorial VSC Converter Theory Basics VSC Control and Modelling VSC system simulations Start –up; DC Fault DC Grid Test Case Cigre B4-57/58 Introductory Basics: LCC Single line VSC: Single Line Diagram Format Symmetrical HVDC Monopole VSC: Unsymmetrical Monopole VSC: Bipole Configuration LCC - VSC Comparison LCC HVDC Mature Technology “Requires” strong ac system Lower losses 0.8% per converter Requires 60% reactive power AC-DC system interactions Harmonics Commutations failure Special Transformers Multi terminal operation possible but hard Controlled DC Current to zero (Idref=0) Dc voltage + to - as alpha changes rectifier to inverter VSC HVDC Rapid growth Helps ac system Control real and reactive power independently Losses reducing 1.1- 1.2% per converter No Commutation failure Less Special Transformers Flexible Dispatch Harmonics with MMC no issue DC Grid (multi-terminal) possible DC voltage is a constant polarity DC Line faults are problematic S1 Multi Terminal For LCC: Rect α < 90 Vdc +ve INV α > 90 Vdc -ve To change Conv 2 from Rect to Inv you must flip the thyristor For VSC: Power Flow is controlled by control signals only S4 S3 f f f S2 VSC Technology is very flexible VSC technology can control two variables together real power and reactive power VSC can generate an AC Waveform…. Black start or island mode possible Many dispatch options available • • Real Power set point • • Use power to control DC voltage Vdc In island mode : use power to control frequency • Reactive Power Q set point • to control Vac magnitude islanded Mode… Use Q Other control targets are possible.. in or out + or - in or out + or – Grid or VSC Operation We tend to think of LCC from AC side to rectifier and generate Dc voltage For VSC ; think from the DC side.. Assume DC Capacitors are charged The capacitor voltages are used to piecewise build ac voltage We the ac voltage waveform and the ac system voltage now we can transfer energy to charge Dc capacitor(s) Transfer P & Q across Reactor Use DC capacitor voltage (Ud) to build an ac Voltage waveform Uc Exchange P based on δ •↑ δ P into Converter Ud ↑ •↓ δ P from Converter Ud ↓ Exchange Q based on |Uc| •↑ |Uc| Q flows into system •↓ |Uc| Q flows from system History of VSC Development: ABB, Siemens and Alstom Grid • VSC Rapid Growth and continue to change • Many projects but few projects have the same design • An MMC type configuration appears to be the “winner” but many marketplace has variations • Not unlike LCC technology 25 years ago • The Final VSC configuration is not decided • and may never occur. PWM Based VSC ABB slide ½ Bridge Multi Module Converter MMC Siemens Slide ½ Bridge MMC with PWM CTLC Full Bridge MMC IET ACDC 2012 Tutorial Gole - Wachal One possible Hybrid Configuration IET ACDC 2012 Tutorial Gole - Wachal VSC Control and Modelling • Control system organization • Look at impact of diode in configuration • High Level Control D Q controller development Development of Voltage reference signals based on dispatched orders Lower level control Valve fire pulses (IGBT firing pulses) Capacitor energy balancing Models For VSC MMC system EMT and RMS transient (Dynamic and loadflow) type models are required Lots of VSC configurations to consider • PWM based (all series devices in Valve switch together) • ½ bridge MMC • ½ bridge MMC with PWM (cascaded two level converter CTLC) • Full bridge MMC • Hybrid mixtures of series valves, ½ and full bridges Traditional ‘emt’ solution methods not effective Emt simulation speed is dependent on number of electrical nodes (size of simulation matrix) MMC configurations increase electrical nodes exponentially • • LCC and PWM VSC • 6 nodes per 3 phase valve • entire valve arm (xx series devices) switch together MMC • Valve may have 400 levels (each switching independent) • 400*6 = 2400 nodes for 1 converter Compare 6 to 2400 …… simulation issue is evident … VSC System Control Model & Levels • Dispatch • • • • • Power Set or Dc voltage (grid mode) Ac voltage reference or MVar set (grid mode) Frequency reference (P) and Ac Voltage (Q) (island mode) Other P& Q strategy High Level Controls • • • • • What is the target of Converter ? Based on dispatch set points (Inputs) Droop setting to allow autonomous control d-q control will generate Vref a, b and c (outputs) Voltage and current limits applied Lower Level Controls • Inputs Vref signals • Valve specific configurations (½ bridge MMC, ½ bridge MMC with PWM, full bridge, etc.) • Capacitor balancing algorithm(s) • Circulating current suppression algorithm(s) • Generates gate pulses and the ac waveforms Control Hierarchy Natural separation occurs Higher Lower level Controls Regardless of Dispatch Orders Higher Level controls develop Vabc Ref Vref A Vref B and Vref C outputs Regardless of converter valve implementation Lower Level controls use the VREF inputs to generate the gate pulses to produce Va Vb and Vc Lower level controls are unique for valve topology and will have ancillary control - Capacitor balance - Circulating current suppression Impact for VSC System Models • • Dispatch and Higher Levels Controls remain same regardless of Converter implementation • Generic or public domain models • Vendor specific (IP) models Lower Level Controls unique for different types of converter • Different Power electronics and control algorithm • Different Capacitor balance algorithm • Different Circulation Current suppression algorithm • Generic or public domain models • Vendor specific (IP) models • Different level of details for each lower level models • Full emt , detailed equivalent, firing pulse RMS From a Simulation Study Point View Choose the appropriate Lower Level Model for your study … How ??? New Model Techniques required Computationally efficient model developed by Simulation Chair University of Manitoba Thevenin equivalent + i1l - Vc1 Ic1 + N1 - FP13 Vc13 Ic13 FP2 Vc2 + - Ic2 - Ic14 + FP3 + FP15 - Vc3 Ic3 - Vc15 Ic15 + FP4 Vc4 + FP14 Vc14 FP16 Vc16 - Ic4 - Ic16 + FP5 Vc5 Ic5 + - - FP17 Vc17 Ic17 + FP6 + FP18 - Vc6 Ic6 - Vc18 Ic18 + FP7 Vc7 + FP19 Vc19 - Ic7 - Ic19 + FP8 + FP20 - Vc8 Ic8 - Vc20 Ic20 + FP9 + FP21 - Vc9 Ic9 - Vc21 Ic21 + N1 FP1 + FP10 Vc10 + FP22 Vc22 - Ic10 - Ic22 + FP11 Vc11 Ic11 + - - FP23 Vc23 Ic23 + FP12 + FP24 - Vc12 Ic12 - Vc24 Ic24 100’s of nodes into 2 nodes Ic(38) Req + Veq - Vc(38) TU(38) TL(38) It makes possible the simulation of Multilevel converters with only a PC n2l U. N. Gnanarathna, A. M. Gole, and R. P.Jayasinghe, "Efficient Modeling of Modular Multilevel HVDC Converters (MMC) on Electromagnetic Transient Simulation Programs," IEEE Transactions on Power Delivery, vol.26, no.1, pp.316-324, Jan. 2011 Start up Concerns Initial Energization • Transformer • MMC Capacitors (Precharge capacitors to 1.41*ELL via diodes) • DC Line or DC Cable Use start-up resistor to limit current. Short resistor with by pass switch Deblock pulses Conv 1 and then Conv 2 Ramp power to desired setpoints Session 3: VSC system start up T1 T2 1000 km P=900 MW Z SCR: 2.5 Z SCR: 2.5 P control Vdc control @ 900 MW @ 640 kV P=966 MW Session 3: VSC system start up De-block Terminal 1 Close AC brk Bypass Pre R De-block Terminal 2 Ramp up Start up sequence (kA) 10.0 Iac T2 (Sending end) -10.0 Edc2 (+) (Vdc control end) (kV) 700 -100 Idc 2 -> 1 (kA) 7.0 -1.0 (-) P1 P2 (MW) 1.00k -0.10k [s] 0.00 0.50 1.00 1.50 2.00 2.50 Summary Issues VSC Start-up During start-up energization of both transformers and all capacitors therefore Larger Inrush Inrush resistor commonly added with bypass switch Diodes: with no firing pulse and diodes will conduct resulting in a Dc voltage VDC=1.41 peak of Vac L-L (charge capacitors and line (or Cable) rww1 DC Line Fault VSC scheme with overhead line (based on Caprivi) no Dc Fast (4 msec) breaker installed Resonant DC Breaker (50-75 msec installed) On DC fault.. Block firing pulse.. MMC capacitors cannot discharge into line but diodes will continue to commutate and feed DC fault (as 6P LCC rectifier) Open AC breaker .. Remove 6p rectifier diode current DC line will discharge slowly.. Based on the R/L circuit of the Dc line will keep the post fault DC current present for seconds up to a couple of minutes . A dc switching action is required to allow Dc fault recovery JCGA1 DC Line Fault - restart Fault detection Valve blocking AC Brk open Fault clearing (MRTB) MRTB reclose AC Brk close Valve deblock Ramp up Start up sequence (kA) 10.0 Iac T2 (Sending end) -10.0 DC fault current (kA) 12.0 -2.0 Edc2 (+) (Vdc control end) (kV) 700 -100 Idc 2 -> 1 (kA) 7.0 -1.0 (MW) 1.0k (-) P1 P2 -0.2k [s] 2.60 2.80 3.00 3.20 3.40 3.60 3.80 4.00 Summary for VSC Dc Line Faults • Pulse Blocking removes discharge of capacitors quickly • AC breaker is required to open to remove 6P diode current. • For a weak ac system .. DC fault draws fault current from AC bus. dc fault = ac fault • Post fault residual dc current requires resonant Dc breaker • For recovery inrush.. MMC capacitors are already charged • Power ramp rate is determined by ac system strength not dc controls . Neutral Return • • • • • Eliminate ground currents Increased line losses DC voltage offset at remote station.. Requires more dc insulation Neutral current can be controlled to zero by bipole controller During pole outage, the pole conductor can be used to reduce losses. DC Grid Modelling Test System (B4-58) B4-57 has developed T-line and cable parameters for test case A base PSCAD and EMPT-RV test cases are available. Models are changing .. Test Case alternatives • Monopole • Bipole with neutral return • Bipole with ground/ sea electrodes. Thank you… Questions?