Process Safety Management

advertisement

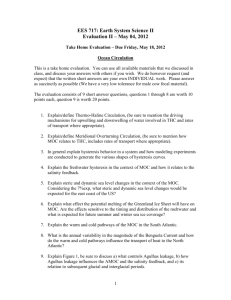

PROCESS SAFETY MANAGEMENT EHS NEWSLETTER Issue 1 Process Safety Management EHS Newsletter December 2014 IN THISDecember ISSUE PROCESS SAFETY MANAGEMENT 2014 PSM Development Update PSM Development Update Process Safety Management Program Development Update; Overview of PSM Focus Group Activities Page 1 Welcome to the 1st Edition of the Process Safety Management – EHS Newsletter. The intent of this internal publication is to provide updates, guidance, information and reference material to the University community impacted by the Process Safety Management (PSM) initiative. Please feel free to share the document or reference the EHS Webpage (www.ehs.psu.edu/) for the on-line version. Program Development Update It doesn’t seem that long ago that the Pegula Ice Arena ceremonial groundbreaking event took place (April 20, 2012) but we have already entered our second Hockey season in one of the nation’s best college hockey venues. Although there has been a lot of visible activity taking place since the Spring of 2012, there has also been a lot of activity behind the scenes when the University embarked on its new initiative to efficiently and safely manage the arena’s new Ice Plant. The initiative is known as Process Safety Management or simply PSM. What is PSM? Basically, it is a defined management system to ensure critical assets are managed and operated within safe limits to minimize the likelihood of a release that could lead to a fire, explosion, exposure, or business interruption. To develop this new program a PSM Focus Group was formed with representatives from Intercollegiate Athletics, College of Agricultural Sciences, Materials Research Institute, Office of Physical Plant and Environmental Health & Safety. The initial focus was associated with the ammonia refrigeration systems within the University which includes a portion of the Creamery operation in addition to the new Ice Plant. The PSM Focus Group has been meeting since April assessing and developing the program elements for the University’s PSM initiative. Based on various inputs including existing programs, process safety culture and wide spread impact to different operating units, the team identified 17 key program elements. To assist the Focus Group, smaller work groups of subject matter stakeholders were formed to focus on specific elements within the PSM program. These “SubGroups” were charged with developing a proposed process that would work in the field to address the requirements of a specific element. More information on the 17 program elements and Sub-Groups will be provided in subsequent Newsletters. Management of Change Brief review of the Management of Change (MOC) Element within the Process Safety Management Program Page 2 PROCESS SAFETY MANAGEMENT EHS NEWSLETTER | Issue 1 2 Management of Change EQUIPMENT – ACCESS CONTROL Management of Change, or MOC, is one of the 17 elements within the University’s PSM program. What is an MOC? Keep reading to learn more about the element purpose and associated requirements within the University’s PSM program. What is an MOC? Equipment Understanding equipment safe operating conditions, defined written procedures and maintaining equipment are critical components of the PSM program. Access Control Due to the unique hazards associated with PSM Covered Areas, additional training requirements are required for access into these areas. PSM – BY THE NUMBERS 100% Percentage of Developed and Approved Compliance Guidelines for each of the 17 Program Elements 81% Percentage of Approved Written Procedures for the 17 Program Elements FOR MORE INFORMATION Contact: Charles Williams, Process Safety Program Manager, EHS Dept. for more information on Penn State’s PSM Program 865-6391 cmw33@psu.edu Have you ever heard that change is constant? Did you ever ask yourself what series of incremental changes were introduced to some aspect of your work environment that lead you to the current situation? Change can and should be good – without change processes can become outdated, inefficient or less competitive. When it comes to PSM, change is also good but it needs to be appropriately managed and assessed prior to implementation. Therefore, the purpose of the MOC element within PSM is to manage changes to process chemicals/biological agents, technology, equipment, procedures; and changes to facilities or organizational changes that affect a covered process. Prior to making a change certain considerations must be addressed including: ○ technical basis for the proposed change ○ impact on health, safety and the environment ○ modifications to operating procedures ○ notification and training affected employees ○ how are any risks associated with the change appropriately managed In almost every situation, a single person within the work unit or University would be unable to consider all the above issues prior to implementing a change, so a review team has been developed. These individuals who must be familiar with the covered process are charged with considering the potential overall impact to the process prior to implementing the change. To facilitate this review process, an MOC Form has been developed by the MOC SubGroup (MOC Form available on the EHS Webpage under the Workplace Safety tab and Process Safety Management button (http://www.ehs.psu.edu/workplacesafety/process-safety-management). The MOC Form must be prepared by the individual or department proposing to make a change within the covered process area. Sufficient information must be collected for the review team to complete their assessment. For example, with equipment changes specifications including materials of construction, safe operating parameters, and safety systems are required as part of the MOC assessment. Once the scope of the MOC is defined and the appropriate information collected, the Form and supporting documentation is distributed to the review team. To proceed with the change, the entire review team must “Approve” the MOC. After the MOC is Approved by the review team, it isn’t the end of the MOC process. Depending on the complexity of the change (e.g. change in procedural requirements vs. installation of a new heat exchanger) an additional review may be required prior to restarting the covered process area. For changes that involve equipment, a PreStartup Safety Review (PSSR) is required to ensure the field installation was completed as it was designed and approved through the MOC review. Does Every Change Require an MOC? Almost every change will require an MOC; however, if it can be considered an “In-Kind Replacement”, the MOC process is not required. What is an In-kind Replacement? It is basically any process or equipment change performed in accordance with established design specifications. An example would be replacing a Hansen Solenoid Valve – Model #HS4A with the same valve. CHEMICAL SAFETY BOARD Chemical Safety Board (CSB) – the members of the CSB Board identified modernization of Process Safety Management Regulations (OSHA 29 CFR 1910.119) as the Agency’s Second “Most Wanted Safety Improvement” [More information to follow in subsequent Newsletters regarding the CSB – stay tuned]