A key element of a design project.

advertisement

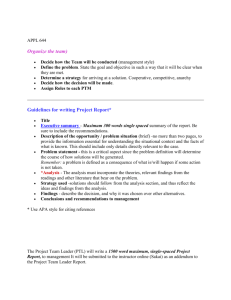

A key element of a design project. You are (nearly) here Product Evaluation Test Planning and Testing The TEST PLAN… Defines Goals of the test sequence. Identifies the specific test procedures, Lists the data to be acquired, Specifies the schedule, and sequence, of testing Specifies Testing Equipment, Facilities to be used Measurement Equipment: Computer-controlled DAQ? Sensors, Transducers; Power source? Accuracy/Resolution? Jigs, Fixtures, and Tools; Availability? Skill required for operation? Product Evaluation Test Planning and Testing The TEST PLAN… Is designed to guide the Validation of both the prototypes components (shape, size, mass etc.), and the performance of the test article Should be able to identify configuration and performance differences (e.g. shortcomings?) between what was envisioned/specified and the fabricated result Provides a direct link from Level 1 Requirements, thru specifications, to actual prototype configuration, and prototype performance. What the Client wanted How the Client explained it How the project manager understood it How the Engineer visualized it How the Engineers designed it How Health & Safety wanted it How the Contractor built it When it was delivered What the Client paid for What the Client received What the client really needed Types of Testing encountered in an industrial setting… 1. Component or system VALIDATION TESTING Testing to verify ANALYSIS predictions Confirm (or invalidate?) assumptions Provide confidence in analysis procedures Determine if further design work is warranted Types of Testing encountered in an industrial setting… (continued) 2. Testing as s COMPANION to ANALYSIS Provide required inputs for (future) analysis Dimensional data? Material Properties? Subsystem Performance? Reverse Engineering? Baseline characteristics of new or unique products, systems, materials must be found in order to support analysis steps leading to an ultimate solution. Types of Testing encountered in an industrial setting…(continued) 3. Testing IN LIEU OF ANALYSIS Some engineering designs are too complex to be adequately or completely analyzed Inadequate modeling capability? Inadequate budget? Lack of time? Complex or Indeterminate structures often cannot be effectively modeled Often, system performance cannot be fully anticipated Testing can establish likely results prior to full engineering implementation: (e.g. Osprey Test) Typical for novel experiments, one-off prototypes, some basic research projects Types of Testing , continued 4. ACCEPTANCE TESTING Often used to verify performance of fabricated or purchased parts Major function of a Quality Assurance department Can also refer to performance of built or assembled delivered system or design Dimensions, Weight, Materials recorded Kinematics & Dynamic Performance observed, recorded Results compared to performance specifications to determine if product performs within required bounds Destructive/Nondestructive testing, sampling Types of Testing, continued 5. SYSTEM - LEVEL VERIFICATION & VALIDATION Comprehensive testing to verify conformance to specifications, interfaces, user requirements Subsets Functional Performance Testing e.g. Climatic Testing to extreme environmental limits… MIL-STD-810 (humidity, high/low temp, salt spray, etc.) Barge Shock Reliability Testing e.g. Repeatability, Cyclic fatigue Compliance Testing Conformance to third-party specs or regulatory rules e.g. UL or CE testing Examples of System-Level tests: Automotive crash testing Endurance testing of transportation systems, vehicles Vibration Acceptance Testing http://www.youtube.com/watch?v=MH0okmOnfVo&f eature=related (Vibe table component test) http://www.youtube.com/watch?v=Q5LbFdfVDqE&fe ature=related (Vibe table computer test) MSU Student-Accessible Resources M&IE Test Facilities Materials Testing Laboratory Instron Tensile/Compressive Testers, Drop Tower (Impact) MSU Subzero Test Facility, ICAL, etc. Instrumentation Lab Sensors, Transducers, DAQ Hardware Machine Shop Inspection Equipment Standard QA Equipment – Surface Plates, Gage Blocks, Height Gages, Calipers CIM Lab Micro-scribe Sponsor’s Facilities, 3rd – Party Shop Instructor or Advisor Assistance Documentation Discussion Prototype testing provides one of the best opportunities to DOCUMENT your achievements, and to demonstrate that you’ve met your “Level 1 contractual requirements: To do so, be absolutely sure to TAKE PHOTOS/VIDEOS of tests in progress and of test results. Many groups will utilize MSU Data acquisition equipment and transducers to record signals (pressures, strains, forces, velocities, temperatures, etc. In those cases, it is important to capture the LabVIEW (or other) programming, and to clearly document any postprocessing of data. Also be sure to record identification of all components, provide info on sensors (range/resolution/accuracy) names of data files, computer and software ID, etc. This ensures repeatability (if necessary.) Specific TEST PLANNING Documentation Requirements Test Plan – Due to drop box by 5:00 PM FRIDAY 1. A well-written plan documenting the specific procedures that will be used to inspect and test your prototype components, assembly Include schedule and location of testing Include equipment to be utilized Include the specific DATA to be acquired Each test plan MUST include the groups assessment of any and all safety concerns related to testing, operation. The plan must specify the means you’ll utilize to mitigate or eliminate any safety-related issues. Safety is the one issue we cannot ignore – your health and well-being is paramount. Watch out for existing or unanticipated hot/sharp surfaces, high pressures, dangerous forces, risk of explosions or catastrophic failures, etc. This is a critical element. EVERY GROUP should solicit the advice/opinion of their MSU Advisor prior to undertaking any testing, as a means to ensure that adequate Safety Protocols are in-place. Include discussion of how your data will be Processed and Presented Specific TEST PLANNING Documentation Requirements 2. Technical Addendum – Due at end of term Test plan documents including procedures, protocol, and results A) acceptance testing details for your tests & measurements of fabricated or purchased parts, assemblies must be included in the final technical addendum B) functional testing procedures and results must also be included in the final technical addendum Formatting of Technical Addendum includes other elements, but test procedures and RESULTS are one of the highlights A well written and well-executed test plan supports and helps to highlight project success.