Assignment 7 Solutions 12.9 Annual Demand in Units

advertisement

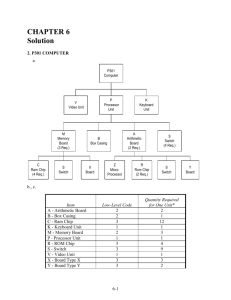

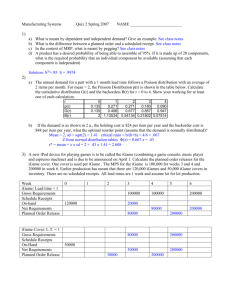

Assignment 7 Solutions 12.9 Annual Demand in Units Setup Cost for Each Order Holding Cost per Unit per Year Lead Time for a New Order in Days D = 1,500 S = $150 H = $45 L=6 a) Q* = b) Annual Holding Cost = (Q / 2) H = (100 / 2) $45 = $2,250 2 1,500 $150 2DS = = 100 $45 H The economic order quantity is 100 units per order. The cost of holding the component in inventory is $2,250 per year. c) Annual Ordering Cost = (D / Q) S = (1,500 / 100) $150 = $2,250 The cost of ordering the component is $2,250 per year. d) ROP = dL = (1,500 / 300) 6 = 30 units A new order should be placed when there are 30 units left in inventory. 12.23 Annual Demand in Units Setup Cost for Each Order Holding Cost Percentage D = 100 S = $45 I = 20% We evaluate the economic order quantity for each level of quantity discount: 9 sheets or less. Unit Price P = $18.00 Q* = 2DS = IP 2 100 $45 = 50 units 0.2 $18.00 10 to 50 sheets. Unit Price P = $17.50 Q* = 2DS = IP 2 100 $45 = 50.7 units (ie 51 units) 0.2 $17.50 More than 50 sheets. Unit Price P = $17.25 Q* = 2DS = IP 2 100 $45 = 51.1 units (ie 52 units) 0.2 $17.25 Now, what answer do we give? There are two approaches possible: Approach #1: Calculate the total cost for each alternative. TC1 TC2 TC3 = (D / Q) S + (Q / 2) H + PD = (100 / 50)$45 + (50 / 2)(0.2)$18 + (100)$18 = $1,980 = (D / Q) S + (Q / 2) H + PD = (100 / 51)$45 + (51 / 2)(0.2)$17.50 + (100)$17.50 = $1,927.48 = (D / Q) S + (Q / 2) H + PD = (100 / 52)$45 + (52 / 2)(0.2)$17.25 + (100)$17.25 = $1,901.24 Option three has the lowest total costs, so this is the choice we should recommend. Approach #2: Common Sense Both quantity one (50) and quantity two (51) put the company in the range where the 50 and over discount will apply anyways. Calculations of total cost for these quantities are inappropriate because the supplier will not sell at the given costs for the economic order quantity. Hence quantity three (52) is the one to choose. 13.3 Note that we cannot quantify all costs for this plan (such as the cost of production), but we will evaluate the costs for the information given. We can determine the following costs: Stockout ($100 per unit) Inventory Holding ($20 per unit per month) Hiring ($5,000 per 100 units) Firing ($7,500 per 100 units) These costs also suggest the we should be keeping track of inventory from month to month and thus also production and demand from month to month. The way I read the question is: Under this plan, we produce this month what was demanded last month – in this case ‘demand’ is the aggregate demand forecast provided in the table; Inventory levels will therefore fluctuate because production this month does not match demand this month; and, If inventory is exhausted and demand is greater than production, a stockout cost will be incurred. We prepare the following chart to evaluate the plan: Period 1 2 3 4 5 6 7 8 Totals Expected Demand 1400 1600 1800 1800 2200 2200 1800 1400 Beginning Inventory 200 400 200 0 0 0 0 400 Production 1600 1400 1600 1800 1800 2200 2200 1800 Ending Inventory 400 200 0 0 0 0 400 800 1800 Stockout Hiring Firing 0 0 0 0 400 0 0 0 400 0 0 200 200 0 400 0 0 800 0 200 0 0 0 0 0 400 600 So the costs that we can measure for this problem are: Inventory Carrying = 1800 x $20 Stockout = 400 x $100 Hiring = 800 / 100 x $5,000 Firing = 600 / 100 x $7,500 Total Costs (excluding production) = $36,000 = $40,000 = $40,000 = $45,000 = $161,000 How this was marked: yes, this was an obtusely-worded question. You received full marks on this question for identifying and accurately calculating at least two of the above four costs. Just don’t expect me to be nearly so nice on the final exam. 13.9 Plan A: Period 1 2 3 4 5 6 Total Demand 1000 1200 1400 1800 1800 1600 Production 1000 1000 1000 1000 1000 1000 Subcontracting 0 200 400 800 800 600 2800 Subcontracting Cost = 2800 x $60 = $168,000 Total Costs (excluding production) = $168,000 Plan B: Period 1 2 3 4 5 6 Total Demand 1000 1200 1400 1800 1800 1600 Production 1300 1000 1200 1400 1800 1800 Hire 0 200 200 400 0 0 800 Fire 300 0 0 0 0 200 500 Hiring Cost = 800 / 100 x $3000 = $24,000 Firing Cost = 500 / 100 x $6,000 = $30,000 Total Costs (excluding production) = $54,000 Why are there no inventory carrying or stockout costs here? Note the subtle difference between this plan and the plan in question 13.3. Question 13.3 says ‘chase strategy’ but then explicitly states that production in a month should equal demand in the prior month, causing inventory carrying or stockout costs. Conversely, this plan states that workforce will be varied to meet demand in the current month, and this is the generally accepted definition of a ‘chase strategy’ plan. Once again feeling generous, you will not be marked down for including inventory carrying or stockout costs in your analysis of this plan, but be wary of this point on the final exam. We would select Plan B, which has a lower cost. 14.11 a) To develop a Gross Requirements Plan for item C, we note from the diagram that one of item C is used in Assembly A and another is used in Assembly H. Note that existing inventories aren’t taken into account in a gross requirements plan. Our plan should thus show requirements for all three components: Item A Gross Req Order Rel H Gross Req Order Rel C Gross Req Order Rel 1 2 3 4 5 6 7 8 100 100 100 100 9 10 50 50 100 100 100 50 100 50 11 12 150 150 50 50 50 50 150 150 b) Our net requirements plan does taken into account existing inventories and provides us with some more detailed quantities. Once again, it should show items A, H, and C: Item A Gross Req On Hand Net Req Planned Receipt Planned Release H Gross Req On Hand Net Req Planned Receipt Planned Release C Gross Req On Hand Net Req Planned Receipt Planned Release 1 2 3 4 5 6 7 8 100 9 100 100 100 50 50 50 50 50 50 100 100 100 50 50 0 50 100 50 100 100 50 50 10 50 50 50 150 50 100 100 50 50 50 0 50 50 150 50 50 0 50 50 20” Fan Frame Grills (2) Handle Supports (2) Hub Fan Assembly Blades (5) Electrical Motor Knob Switch 12 150 150 150 50 100 14.13 a) The product structure diagram is: Housing 11 150 0 0 150 150 b) The time-phased product structure is: Frame Support Handle Housing Grills Fan Hub Fan Assembly Blades Motor Switch Knobs 1 2 3 c) The net material requirements plan is: 4 Elec 5 6 7 Lot Size Lead Time 1 1 2 3 1 2 On Hand 100 100 200 150 Item ID 20” Fan Housing Grills Fan Assembly Electrical Unit Frame 1 Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases 2 3 4 5 6 900 900 100 800 800 800 1800 200 1600 1600 1600 900 150 750 750 750 900 900 900 900 800 800 800 800 7 1000 100 900 900 Lot Size Lead Time 1 1 On Hand 50 400 1 100 2 1 Supports Handle Hub Blades 1 12 Item ID Motor 20 Switch 1 Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases Gross Requirements Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases 2 3 4 5 1600 50 1550 1550 6 7 50 50 1550 800 400 400 400 400 750 750 750 750 3750 50 50 3750 3800 3800 900 900 900 900 900 20 880 888 888 8 Lot Size 25 Lead Time 1 On Hand Item ID Knob 1 Gross Requirements Scheduled Receipt Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases 2 3 4 5 900 200 200 200 700 700 200 700 6 7