Modelling and Control of Linear Combustion Engine (LCE)

advertisement

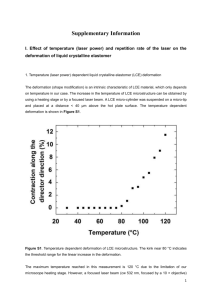

Modelling and Control of Linear Combustion Engine (LCE) Pavel Němeček, Ondřej Vysoký, Michal Šindelka Czech Technical University in Prague Faculty of Electrical Engineering Department of Control Engineering Internal Combustion Engines inline flat (boxer) V Crank shaft turns the piston's up and down motion into circular motion Series Hybrid Car Gasoline engine turns a generator Generator can either charge the batteries or power an electric motor that drives the transmission Thus, the gasoline engine never directly powers the vehicle and no rotation needed ?! Linear Combustion Engines single hit – easy industrial staplers how to achieve repetitive (periodic) motion??? by proper configuration and control LCE – animation Two-stroke, Two opposite cylinders (2x50 ccm) Pistons directly connected by rod (no crankshaft) Direct air assisted fuel injection Contains linear electric motor-generator - enable starting of LCE - provide conversion to electric energy - enable intervention when misfire occurs No mechanical output, application for serial hybrid vehicles Control, control, control ! Schematic diagram of LCE Advantages of the LCE Elimination of friction losses - associated with the crankshaft and it’s accessories - piston friction reduction (no angular loading) => higher efficiency High power density Compact shape (allow non-standard inbuilt) Reduced amount of moving parts - increase durability - simplify mechanical construction - simplify lubrication Compression ration is not fixed => theoretically multi-fuel operation is enabled Phases of LCE research Designing of the simple model, which allow study of the basic LCE behavior Building up of an experimental prototype of the LCE and validation of the model Control algorithm design for achieving a steady operation Controller’s optimization with respect some criteria of quality (efficiency, emission, power etc.) Design of a power management strategy of a serial hybrid vehicle with the LCE as the main power unit Model of the LCE nonlinear scavenging, non homogenous mixture 3 order Model of Electric motor-generator Model of Combustion Engine Block diagram of the control system PC with dSpace DSP board Interface board On system variable measurement MAF IGBT bridge Position senzor Load resistor Throttle regulator Ignition coil Ignition unit Power switch Power supply 3-phase network Injection control unit Linear-motorgenerator Requirements for the control system of the linear electric motor-generator Collision avoiding between the piston and the cylinder head Maximization of drained electric power in each cycle Prevention of the LCE from stopping when a misfire occurs Starting of the LCE (with respect to a actual LCE state) Experimental results Long term steady operation was achieved Position [m] Max. drained electric power: 400 W at 1200 rpm Time [s] Velocity [m] Experimental results Position [m] Experimental results 6 3 p-V diagram comparison x 10 Simulated Experimental (filtered) 2.5 p [Pa] 2 1.5 1 0.5 0 0.5 1 1.5 2 2.5 3 V [m ] 3 3.5 4 4.5 -5 x 10 Video – LCE prototype in operation Conclusion and further work Conclusion Long term steady operation was achieved Efficiency of the present experimental prototype is low, but it allow study of the system behavior Further work Optimization of the thermodynamical cycle Design and construction of a new prototype in cooperation with mechanical engineers to increase efficiency and durability of the LCE