ELECTRICAL SAFETY RELATED WORK PRACTICES FOR GENERAL INDUSTRY S- 1

advertisement

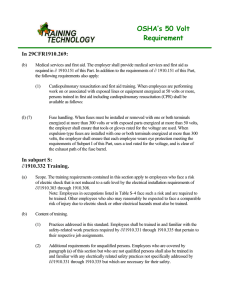

ELECTRICAL SAFETY RELATED WORK PRACTICES FOR GENERAL INDUSTRY S- 1 ELECTRICAL HAZARDS What is an electrical hazard? Electricity and the Human Body Electrocution Arc Blasts & Pressure Waves Secondary Effects S- 2 Types of Electrical Hazards Electrocution Arcs & Blasts Secondary Hazards (fire, falls) An electrical hazard is any potential threat to health and or property caused by inadvertent contact with, or release of, electricial energy. S- 3 Electrical Shocks Resistance of human body varies widely; 10,000 ohms is “typical”. 5mA of sustained current is usually considered the threshold value of physiological damage . Threshold voltage=10,000 ohms x .005 amps or 50 volts. S- 4 Electricity and the Human Body At 5 mA pain begins. At 10 mA paralysis of limbs (arms) occurs. At 30 mA breathing stops. At 75 mA fibrillation occurs. Above 250 mA fibrillation ceases. At 4 amps breathing ceases. At 5 amps tissue burns. S- 5 Arc Blasts & Pressure Waves Injuries & deaths due to arc burns are roughly one fourth of electrical hazard related casualties. Radiation burns can kill up to 5 ft Arc temperatures up to 30,000 degrees Pressure waves created by arc blasts have been known to knock walls down at 30 ft! S- 6 Electricity is the “perfect” hazard: it can’t be seen, smelled or heard! The grim statistics from the Natonal Safety Council: Between 500-600 people in the U.S. die by electrocution or arc blast yearly. 350-400 workers die by electrical current yearly. Electrical accidents are the 8th leading cause of death in the workplace. All electrocutions are preventable! S- 7 THE 4 LINES OF DEFENSE TRAINING FOR ALL AFFECTED PERSONNEL PROPER EQUIPMENT SELECTION OF PROPER WORK PRACTICES PLANNING AND PROCEDURES S- 8 APPLICATION OF OSHA SRWP IN THE WORKPLACE Who Needs Training? What Kind of Training? Work Practices Proper Selection & Use of Equipment Are Written Procedures Necessary? S- 9 WHO NEEDS TRAINING? Anyone who works on or near enough to exposed live parts or parts which might become energized (potential hazard) must receive training. Examples : Electricians, construction crews on industrial sites, heavy equipment operators, machine operators, janitors-in short, potentialy anyone at your facility! S- 10 WHAT KIND OF TRAINING? Training requirements depend on the extent of potential exposure. Training may be OJT or classroom or both. Extent of training depends on whether person is qualified or unqualified. S- 11 Qualified vs Unqualified DEFINITION : A qualified person (OSHA definition) is “one who is familiar with the construction and operation of the equipment and the hazards involved.” This definition applies to specific equipment. S- 12 TRAINING Training required for both qualified and non qualified personnel working on or near parts which are energized or might be energized. Qualified personnel must be trained in work practices, determine nominal working voltage, know line clearances. Unqualified personnel working in vicinity must be trained to extent necessary. S- 13 Training for Qualified Personnel Must be able to identify energized parts. Ability to determine nominal workimg voltages. Must know applicable clearances vs voltages IAW 1910.333(c). Trained in SRWP as applied to job. S- 14 Training for Unqualified Personnel Unqualified trained to the extent necessary. EXAMPLE: Housekeeping crews should be shown safe cleaning distances from equipment with live circuits and instructed in the use of nonconductive cleaning techniques in potentally conductive locations. S- 15 Training for Unqualified Personnel (Con’t) EXAMPLE: Machine operators trained in their role in LOTO. EXAMPLE: Fork lift operators instructed by memo and verbally to avoid certain overhead line locations in your plant. EXAMPLE: Manufacturing personnel instructed by supervisor to avoid barricaded areas. S- 16 Occupations Requiring Training Blue collar supervisors Elec/electronic engineers, techs, assemblers Electricians and welders Industrial machine operators mechanics,repairers, painters, riggers, roustabouts,stationary engineers S- 17 Selection and Use of Safety Related Work Practices Parts must be deenergized before work except as noted in 1910.333(a)(2) and less than 50 volts. 1910.333(a)(1) Work can be performed on energized parts in case of infeasibility or increased hazard of deenergized parts. 1910.333(a)(2) Deenergized parts must be treated as energized or locked out. 1910.333(b)(1) S- 18 Lockout/Tagout (LOTO) LOTO subject to OSHA review. 1910.333(b)(2)(i) Procedures must be in place before deenergizing circuits. 1910.333(b)(2)(ii) Rules governing use of locks and tags. 1910.333(b)(2)(iii) Verification of deenergization required. 1910.333(b)(2)(iv) Restart procedures. 1910.333(b)(2)(v) S- 19 Safety Related Work Practices for Exposed Energized Parts Only qualified personnel may work on energized equipment. 1910.333(c)(2) Overhead lines. Deenergize or protective measures. Minimum approach distances. 1910.333(c)(3) S- 20 LIVE PARTS 3 ft for 0-150 volts 3 ft for 151-600 volts INSULATED PARTS OR WALL Condition a LIVE PARTS LIVE PARTS 3 ft for 0-150 volts 3.5 ft for 151-600 volts Condition b 3 ft for 0-150 vollts 3.5 ft for 151-600 volts Condition c GROUNDED PARTS LIVE PARTS WORKING CLEARANCES, LIVE PARTS, 0-600 VOLTS From Table S-1, 29 CFR 1910 S- 21 APPROACH DISTANCES TO LIVE PARTS Flash Limited Protection Space Required Flash Protection Boundry A Restricted Prohibited Space Space Exposed Live Part, Fixed B C A.Qualified personnel only B. Qualified personnel, approved plan, PPE. C. All requirements in B plus specific training & risk assesment. Adapted from NFPA 70E, Ch. 2-21 S- 22 APPROACH DISTANCES TO LIVE PARTS, 300 V & LESS Flash Limited Protection Space Required Flash Protection Boundry A Restricted Prohibited Space Space Exposed Live Part, Fixed B C A.Qualified personnel only B. Qualified personnel, approved plan, PPE. C. All requirements in B plus specific training & risk assesment. Distances from live part to outer boundries Flash protection: 3 feet Limited space: 3 1/2 feet Prohibited space avoid contact S- 23Restricted space avoid contact APPROACH DISTANCES TO LIVE PARTS, 751 to 2,000V Flash Limited Protection Space Required Flash Protection Boundry A Restricted Prohibited Space Space Exposed Live Part, Fixed B C A.Qualified personnel only B. Qualified personnel, approved plan, PPE. C. All requirements in B plus specific training & risk assesment. Distances from live part to outer boundries Flash protection: 4 feet Limited space: 4 feet Prohibited space: 3 inches S- 24Restricted space: 2 feet Work Practices (Con’t) Procedures required for handling all conductive materials. 1910.333(c)(6) Nonconductive ladders. 1910.333(c)(7) Conductive apparel must be insulated. 1910.333(c)(8) Adequate Illumination required. 1910.333(c)(4) and ANSI 11.1 S- 25 Work Practices (Con’t) Safeguards required for housekeeping duties. 1910.333(c)(9) Interlocks: only qualified personnel may defeat and only on a temporary basis. 1910.333(c)(10) Alerting techniques required in exposed hazardous locations. 1910.335(b) S- 26 Electric Power & Lighting Live load disconnects must be load rated. Breakers not marked “SWD” cannot be used to make\break live loads! Breakers operated under fault conditions must be replaced. Breakers operated under overload should be examined. It is unlawful to degrade overload S- 27 protection in the workplace! ungrounded cord 2 wire cord with pigtail COMMON CORD AND PLUG VIOLATIONS S- 28 WORKING ON OR NEAR EXPOSED LIVE PARTS REQUIRES PERSONAL PROTECTIVE EQUIPMENT:29 CFR 1910.333(c)(2). EXPOSED BODY PARTS MUST BE PROTECTED: 29 CFR 1910.335(a)(1). S- 29 Portable Electrical Equipment HANDLING: Tools shall not be handled by connecting cords or unsafely. VISUAL INSPECTION FOR DAMAGE. Must have grounding conductor or be double insulated or be battery operated. Tools used in damp or wet locations must be rated for use in those environments. Attachment plugs cannot be altered! S- 30 TEST EQUIPMENT Only qualified personnel are permitted to use test equipment on live circuits. Test equipment must be used within ratings. S- 31 Safeguards for Personnel Protection Protective equipment is required in hazardous locations. 1910.335(a)(1) General Equipment & Tools. Insulated tools required when working near exposed live parts. Includes fuze pullers/installers,ropes, shields,etc. 1910.335(a)(2) S- 32 Are Written Procedures Necessary? Written procedures increase training effeciency, protect employer and employee. Written procedures are required for Lockout/Tagout. Procedures required for both enclosed and confined work spaces. 1910.335(c)(5) S- 33 Acnowledgements Ralph H. Lee Electricity and the Human Body, IEEE Transactions Accident Facts, National Safety Council, 1996 ed. Jack McDaniel Work Book for Electrical Safety Related Work Practices and Lockout/Tagout for General Industry James G. and James W. Stallcup Electrical Regulations Simplified S- 34