Development of Portable Charger for Mobile Phone Using

advertisement

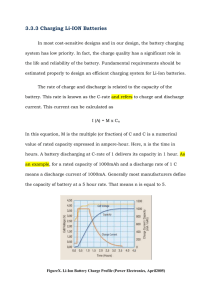

Development of Portable Charger for Mobile Phone Using Arduino Microcontroller during Disaster Recovery Teddy Surya Gunawan, Mira Kartiwi, Nur Ranis Sabrina Suhaimi, Rashidah Abu Bakar Electrical and Computer Engineering Deportment Information Systems Deportment International Islamic University Malaysia Advisor:趙春棠 Postgraduate:王嘉帷 Outline Abstract Introduction Purpose Materials and Methods ◦ Energy Harvesting ◦ DC/DC Boost Converter ◦ Intermediate Battery ◦ Li-Ion Charging Circuit using Arduino Performance Evaluation Conclusions References Abstract The objective of this research is to design and develop a portable charger for mobile phone using Arduino microcontroller, which can be used effectively during disaster event. Introduction Figure 1. Model of Disaster Recovery Activities Introduction Figure 2. The Cause of Telecommunication Failure during Disaster Introduction Development of Portable Charger Figure 3. Design of mechanical and solar powered portable charger Purpose In this paper, the intended portable charger will be used during emergency response as highlighted in Figure 1. More specifically, the emergency response phase begins with the search and rescue period and emphasizes fulfilling the basic needs of individuals. Materials and Methods Energy Harvesting The energy harvesting part consists of solar and mechanical power source. As shown in Figure 3, the hand crank mechanical system tested is able to produce between 3 to 4V while the solar panel tested is able to produce between 3 to 6V. Materials and Methods DC/DC Boost Converter To charge the 12 V intermediate battery, a DC/DC boost converter is required to pump up the appropriate voltage. It is a DC/DC step up voltage converter that will take in a DC voltage and output a higher DC voltage. Materials and Methods DC/DC Boost Converter Figure 4. DC/DC Boost Converter using LM2577T Materials and Methods Intermediate Battery Sealed Lead Acid Battery (SLA 密封式鉛酸電池) The SLA form is very similar to lead acid battery except that the electrolyte is in the form of a gel rather than a liquid. It is basically a maintenance free battery. Materials and Methods SLA Battery and Charging Circuit Figure 5. Basic Charging Circuit for Intermediate Battery Materials and Methods SLA Battery and Charging Circuit SLA battery employs float charging method in which the battery is connected to constant-voltage supply continuously as shown in Figure 5, so that it maintains the cell in a fully charged condition. SLA battery is also the cheapest battery among the other rechargeable batteries. Materials and Methods Li-Ion Charging Circuit using Arduino Generally, mobile phone battery using Li-Ion [4] is rated 3.7 volts at 1000 to 1300 mAh while our intermediate battery, SLA having 12 volt rating with a 0.36 A current. The circuit described in Figure 6 provides 7V regulator voltage and sufficient current for the slow charging of the mobile phone. Materials and Methods Li-Ion Charging Circuit using Arduino Figure 6. Li-Ion Battery Charging Circuit using Arduino Microcontroller Materials and Methods Li-Ion Charging Circuit using Arduino Figure 7. Flowchart of Li-Ion Charging Mechanism using Arduino Performance Evaluation Performance Evaluation of Mechanical Energy Figure 8. Testing Performance of Different Types of DC Motor using Hand Drill, Digital Voltage Meter, and Tachometer Performance Evaluation Performance Evaluation of Mechanical Energy Table 1. Performance of Various Dc Motors Performance Evaluation Performance Evaluation of Solar Energy Figure 9. Testing Performance of Solar Panel in Single, Series, and Parallel Configurations Performance Evaluation Performance Evaluation of Solar Energy Table 2. Performance of Solar Panels Performance Evaluation Figure 10. DC/DC Boost Circuit Performance Evaluation Table 3. Charging Time for Li-Ion Battery Performance Evaluation Figure 11. Portable Charger Utilizing Arduino Microcontroller Conclusions The design of portable charger for mobile phone suitable during disaster recovery has been presented. The charger has two power source, mechanical and solar power. Various DC motors and solar panels have been experimented to select the best configuration. A DC/DC boost converted was then used to increase the input voltage from 3V to around 12 V to charge the intermediate battery. Charging time for intermediate battery to be fully charged is about 2 hours, while the mobile phone Li-Ion battery requires about 4 hours to be fully charged. References 1. A. M. Townsend and M. L. Moss, "Telecommunications infrastructure in disasters: preparing cities for crisis communication, " Centre for Catastrophe Preparedness and Response, New York University 2005. 2. ITU, Telecommunication Regulation Handbook, International Telecommunication Union, 2011. 3. F. Patricelli, J. E. Beakley, A. Carnevale, M. Tarabochia, and D. K. J. E. v. Lubitz, "Disaster management and mitigation: the telecommunication infrastructure, " Disasters, vol. 33, pp. 23-27, 2008. 4. M. Chen and G. A. Rincon-Mora, "Accurate, Compact, and Power-Efficient LiIon Battery Charger Circuit, " IEEE Transactions on Circuits and Systems, vol. 53, pp. 1180-1184, 2006. 5. C. D. Rahn and C.-Y. Wang, Battery Systems Engineering, Wiley, 2013. References 6. A. V. d. Rosa, Fundamentals of Renewable Energy Processes, 3rd Edition, Academic Press, 2012. 7. R. J. M. Vullers, R. v. Schaijk, I. Doms, C. V. Hoof, and R. Mertens, "Micropower energy harvesting, " Solid-State Electronics, vol. 53, pp. 684693, 2009. 8. J. A. Paradiso and T. Starner, "Energy scavenging for mobile and wireless electronics, " IEEE Pervasisve Computing, vol. 4, pp. 18-27, 2005. 9. M. McRoberts, Beginning Arduino, 2nd Edition, Academic Press, 2013. 10. J. Lopez, M. Gonzalez, J. C. Viera, and C. Blanco, "Fast-Charge in LithiumIon Batteries for Portable Applications, " in 26th Annual International Telecommunications Energy Conference (INTELEC). Chicago, 2004, pp. 1924. Thank you for listening