DESIGN AND ANALYSIS OF ORIFICES FOR USE TEST LOOPS

advertisement

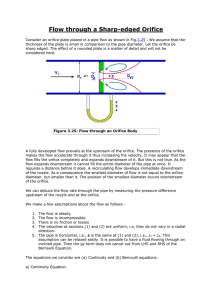

DESIGN AND ANALYSIS OF ORIFICES FOR USE IN NUCLEAR REACTOR COOLANT PUMP TEST LOOPS by Jeffrey Robert Stack An Engineering Project Submitted to the Graduate Faculty of Rensselaer Polytechnic Institute in Partial Fulfillment of the Requirements for the degree of MASTER OF ENGINEERING IN MECHANICAL ENGINEERING Approved: _________________________________________ Ernesto Gutierrez-Miravete, Adviser Rensselaer Polytechnic Institute Hartford, CT December 2011 i CONTENTS LIST OF TABLES ............................................................................................................ iii LIST OF FIGURES .......................................................................................................... iv LIST OF SYMBOLS ......................................................................................................... v ACKNOWLEDGMENT .................................................................................................. vi ABSTRACT .................................................................................................................... vii 1. Introduction.................................................................................................................. 1 2. Theory & Methodology ............................................................................................... 5 3. Results and Discussion ................................................................................................ 7 3.1 Determination of Required Orifice Differential Pressures................................. 7 3.2 Sizing of Orifice 1 .............................................................................................. 9 3.3 Sizing of Orifice 2 ............................................................................................ 12 3.4 Numerical Method for Calculation of Orifice Pressure Drop .......................... 14 3.5 Static Structural Analysis of Orifice ................................................................ 20 3.6 Modal Analysis of Orifices .............................................................................. 28 4. Conclusions................................................................................................................ 31 5. References.................................................................................................................. 33 Appendix A: Orifice Mode Shapes.................................................................................. 34 ii LIST OF TABLES Table 1: COMSOL Mesh Comparison ............................................................................ 16 Table 2: ANSYS Mesh Comparison................................................................................ 23 Table 3: Orifice Natural Frequencies .............................................................................. 29 iii LIST OF FIGURES Figure 1: Examples of Cavitation Damage [3] .................................................................. 2 Figure 2: Pump Impeller & Diffuser [5] ............................................................................ 4 Figure 3: Typical Pump Curve .......................................................................................... 7 Figure 4: Pump Curve with Two Operating Points ........................................................... 8 Figure 5: Diagram of Thick-Edged Orifice [6]................................................................ 10 Figure 6: Geometry of COMSOL Model ........................................................................ 15 Figure 7: Auto-Meshing of COMSOL Model ................................................................. 15 Figure 8: Velocity Streamlines through COMSOL Model .............................................. 17 Figure 9: Magnified View of Recirculation Zone ........................................................... 17 Figure 10: Pressure Contour Plot ..................................................................................... 18 Figure 11: Pressure Along Axis of Symmetry ................................................................. 19 Figure 12: ANSYS Workbench Geometry ...................................................................... 21 Figure 13: ANSYS Workbench Model Meshing............................................................. 22 Figure 14: COMSOL Pressure Plot Along Orifice Face ................................................. 24 Figure 15: Setup of ANSYS Model ................................................................................. 25 Figure 16: Deformation of ANSYS Model ..................................................................... 26 Figure 17: Stress Intensity of ANSYS Model ................................................................. 26 iv LIST OF SYMBOLS Dh = hydraulic diameter of the orifice (m) F0 = flow area of orifice (m2) F1 = flow area of upstream and downstream piping (m2) k = spring constant for natural frequency (unitless) m = mass (kg) po = system pressure (Pa) pv = vapor pressure of fluid (Pa) Q = pump flow (m3/s) Re = reynold’s number (unitless) w1 = stream velocity of fluid (m/s), expressed as flow (m3/s) / orifice flow area (m2) γ = specific weight of fluid (kg/m3) ι = thickness of orifice (m) λ = friction factor inside orifice inner diameter (unitless) ρ = density of fluid (kg/m3) ν = kinematic viscosity (m2/s) ωn = natural frequency (rad/s) Δp = pressure difference (Pa) Δz = elevation difference between pump and system pressure measurement (m) Σhl = head losses between system pressure measurement and the pump (m) v ACKNOWLEDGMENT I would like to express my gratitude to Dr. Gutierrez-Miravete for support throughout this project and through my degree program. I would also like to thank all of my family and friends that supported me through my time spent at Rensselaer Polytechnic Institute. Finally, I would like to express my gratitude to my professional associates that have provided support for through the program. vi ABSTRACT This report describes results from a project aimed at sizing orifices installed in a typical test loop for Reactor Coolant Pumps (RCPs) for use in Pressurized Water Reactor (PWR) power plants. These orifices are used to simulate the hydraulic resistance of the Reactor Coolant System (RCS) in a PWR power plant, which includes the resistance of the reactor core and steam generators. PWR power plants use centrifugal, single-stage RCPs to cool the reactor and transfer heat to the steam generators. These RCPs are typically required to be full-scale performance tested prior to shipment to the power plant site to ensure they meet all design requirements. To perform this testing, the RCPs are temporarily installed in test loops where water is circulated through the loop at different operating conditions. In this project, both analytical and numerical methods are used to size the orifices such that they accurately simulate the system resistance of the RCS for use in the test loop. Using results from the sizing calculations, a static structural analysis is performed to confirm that the orifice design can withstand the hydraulic forces seen during testing. Finally, a modal analysis is performed to determine the orifice natural frequencies. These natural frequencies are compared with RCP hydraulic pressure pulsation frequencies to ensure that they do not overlap and induce a harmonic excitation of the orifices. vii 1. Introduction Reactor Coolant Pumps (RCPs) are the main pumps in a Pressurized Water Reactor’s (PWRs) Reactor Coolant System (RCS), which provide flow of high temperature and high pressure sub-cooled water to the nuclear reactor. This flow cools the reactor and transfers the thermal energy from the reactor to the steam generator, which produces steam to turn turbines, thereby producing power for public consumption. RCPs used in PWRs are typically vertical, single-stage centrifugal pumps as RCPs require large volume flows, minimal pressure pulsations through the RCS and easy access for maintenance. A typical nuclear plant will have between two and four RCPs, each of which circulates on the order of 100,000gpm of water through the RCS [1]. These pumps are generally required to be full scale performance tested prior to shipment to the power plant site. This performance testing proves the mechanical and hydraulic design and functionality of each RCP prior to shipment in order to minimize risk. To test these very large pumps, they must be temporarily installed into a test loop at the manufacturing/testing facility where each pump is operated at various temperatures, pressures and flows to match expected plant conditions. To ensure proper performance when installed into the RCS, many aspects of each pump design must be tested such as hydraulic performance, vibrations, and efficiency, Net Positive Suction Head Required (NPSHR), hydraulic pressure pulsations and expected transient conditions among others. As a result of the required testing, the conditions that the RCPs and the test loop are subjected to are relatively extreme. According to Reference [2], normal operation temperatures are between 530°F (276.7°C) and 590°F (310°C), pressures are typically 2250 psi (15.51MPa) and normal flows are roughly 100,000 gpm [1]. All test loop components must be designed to withstand all potential testing conditions. This includes the test loop piping, any penetrations into the test loop piping, flow meters, orifices and valves. One aspect of the testing program that subjects the pump and test loop to particularly harsh conditions is NPSHR testing. NPSHR is the minimum NPSH required by the pump to avoid damage to the pump hydraulics due to cavitation. Cavitation can quickly 1 cause irreparable damage to a set of pump hydraulics due to the violent shock waves generated as the cavitation bubbles collapse. Figure 1 [3] shows examples of damage caused by cavitation. Figure 1: Examples of Cavitation Damage [3] As a result of the very low system pressures in the test loop during NPSHR testing, cavitation becomes a concern for all parts of the test loop, not just the pump itself. Of particular concern is the main flow restricting components of the test loop that provide the resistance to the pump to simulate the resistances of the reactor internals and steam generators. This is because these components reduce the cross section flow area, resulting in significantly higher flow rates. Since NPSH available is reduced as flow is increased, the high flow rates through these components make them particularly vulnerable to cavitation and its damaging effects. Cavitation damage to test loop components can be detrimental to a testing program. Damage could have effect on their intended resistance, measuring capability or worse, broken components flowing through the test loop could cause irreparable damage to the pump hydraulics. One way to try to prevent cavitation at the main flow restricting components of the test loop is to provide the required pressure drop in stages. For instance, two large inner 2 diameter orifices installed in series would be preferable to one small inner diameter orifice. This is because the velocity of the fluid flowing through the orifice increases as it passes through it. Increasing the velocity is undesirable as Bernoulli’s Principle tells us that as velocity increases, pressure decreases and as pressure decreases so does available NPSH according to the equation below. 𝑁𝑃𝑆𝐻𝐴 = 𝑝𝑜 𝛾 + ∆𝑧 − ∑ ℎ𝑙 − 𝑝𝑣 𝛾 [4] Where: po = system pressure (Pa) γ = specific weight of fluid (kg/m3) Δz = elevation difference between pump and system pressure measurement (m) Σhl = head losses between system pressure measurement and the pump (m) pv = vapor pressure of fluid (Pa) This project designs and analyzes two orifices that simulate the hydraulic resistance of the reactor internals and steam generators and minimize the potential for damage resulting from cavitation during NPSH testing. These orifices would be installed in series to reduce the pressure in two stages to minimize flow constriction and thereby minimizing local velocities and potential for cavitation. More than two orifices are not considered as the number of component and loop penetrations should be minimized considering the extreme conditions the test loop is subjected to. The scope of the project includes designing a two orifice system that would provide the same hydraulic resistance as typical reactor internals and steam generators. The first step is to size the orifices to provide the required resistances. The orifices are sized such that one orifice can be removed to test at a higher flow rate as this is typical in many RCP testing programs. Materials are selected to withstand all conditions. The scope also includes a structural analysis of the orifice plates to ensure that the orifices are suitable for use for such high flows and pressures drops. 3 Finally, a modal analysis of the orifices is performed to ensure that the frequencies of the hydraulic pressure pulsations generated by a typical RCP do not overlap with the natural frequencies of the orifices. A pump’s hydraulic pressure pulsation frequency is generated by the rotating impeller blades passing by the stationary diffuser vanes as shown in Figure 2. Figure 2: Pump Impeller & Diffuser [5] The diffuser is required for flow transition into the pump casing. There is typically a very small gap between the impeller blades and the diffuser vanes, which generates small pressure pulsations that are carried throughout the suction and discharge piping. Although the pressure pulsations are small, they may still be capable of exciting components installed within the piping such as the orifice plates that are designed in this project. 4 2. Theory & Methodology The first step of the problem is to size and design the orifices to provide the required resistances. The dual-orifice system is designed such that both orifices installed in series provide the required resistance to achieve the low flow (rated head and flow) point. Further, they are sized so that when one orifice (Orifice 2) is removed, the remaining orifice (Orifice 1) provides the required resistance to achieve the high flow point. For this high flow point, a slope of the pump curve and a high flow rate is assumed. Then, using this information and the rated head and flow of the RCP, the head and flow of the high flow point is determined and the required resistance of Orifice 1 is known. Once the required resistance of Orifice 1 is known for the high flow condition, it is sized using a correlation from Reference [6]. This results in an inner diameter for Orifice 1. To determine the inner diameter for Orifice 2 (installed to achieve low flow point), the resistance of Orifice 1 is recalculated for the low flow condition and subtracted from the total required resistance (defined by the rated pump head). Then, the same correlation that was used to size Orifice 1 is used to size Orifice 2. Checks of Reynolds Numbers and ι/Dh are performed to ensure that use of the correlation is appropriate. Once the orifices have been sized using analytical methods, the orifice and flow condition that provide the highest pressure drop is solved numerically for comparison with the analytical pressure drop. This also represents the worst case condition for stresses within the orifice and may be used for input into structural analyses, if the numerical methods prove to be more conservative. As a result, numerical flow analysis of only one orifice is necessary. To solve for the pressure drop and the hydraulic forces numerically, the finite element software COMSOL Multiphysics is used. The same geometry and same inputs are used as in the analytical method. The auto-meshing feature of the software is used to generate the number of elements, their size and their shape. Multiple cases are run with different mesh sizes to ensure that the mesh is small enough to produce accurate results. In 5 addition, a minimum distance between the two orifices can be determined from this model. Finally, a structural analysis is performed to ensure that the orifice remains structurally sound throughout all expected testing conditions. This is especially important considering that any damage to the orifices could result in damage to the pump hydraulics, which is the saleable equipment. 3-D models of the orifice designs are then generated using the finite element software ANSYS Workbench. These models are then analyzed for the worst-case scenario, which is defined as the orifice and flow condition that provide the greatest pressure drop. Resulting stresses are compared to the yield strength of the selected material to confirm the appropriateness of the assumed material and orifice thickness. An additional modal analysis of the orifices is performed to ensure that the frequencies of the hydraulic pressure pulsations generated by a typical pump do not overlap with the natural frequencies of the orifices. This modal analysis is performed on both orifices as a conservative condition does not exist. Natural frequencies of the both orifices are compared with hydraulic pressure pulsations of a typical RCP. 6 3. Results and Discussion 3.1 Determination of Required Orifice Differential Pressures The first step in defining the geometry of the two orifices that will be used to simulate the hydraulic resistance of the main Reactor Coolant System (RCS) is to determine what resistances will be required of them to achieve the desired test flow rates and corresponding heads. A pump’s operating point is defined by the intersection of the pump head curve and the system resistance curve as shown below in Figure 3. Pump Performance Curve Head Operating Point System Resistance Curve Flow Figure 3: Typical Pump Curve Of course, the most important flow rate for the pump to be tested at is the normal operating or rated flow rate of the pump. This is the flow rate at which the pump is expected to operate under the normal steady-state plant operating condition. However, typical test programs for pumps, especially of this size, require the pump to be tested over a range of expected flows. For RCP’s in particular, the system resistance of the 7 RCS can be much lower than the normal operating system resistance if only one pump is operating. This may be the case during plant start-up. As a result, testing at a high flow point in addition to a low flow point is typical in testing programs for RCP’s. Figure 4 below shows how a pump operating point changes with a change to the system resistance. Low (Normal) Flow Test Point 2 Orifices Installed Head in Series High Flow Test Point 1 Orifice Installed Flow Figure 4: Pump Curve with Two Operating Points To simulate two significantly different operating points, one orifice is sized such that it will simulate the minimum system resistance alone (without the other orifice installed) to achieve the high flow point. The other orifice is sized such that it provides additional resistance to test at the rated flow rate of the pump. For this configuration, both orifices are installed in series in the test loop. 8 The first step in sizing the orifices is to define the head and flow of the two test points. The head is necessary as the required differential pressure (DP) across the orifice is defined by the head of the pump. Flow is the test parameter that is typically required by the test program. To define the two test points, the rated head and flow of Doosan’s APR1400 Class Reactor Coolant Pump are chosen [7]. This pump was chosen as the rated head and flow are relatively large as they will be used in a 1400MW power plant. The large head and flow of this pump will provide generally conservative conditions at the orifice plate. The rated head of the Doosan APR1400 Class RCP is 114.3m and the rated flow is 7.672m3/s [7]. This will be the first of the two test points and will be referred to as the rated test point. Both orifices installed in series will provide the resistance so that the pump operates at this point. To determine the high flow test point, the slope of the pump curve and the required test flow must be assumed as this is not information that is publically available. Considering, it is assumed that the pump curve is linear, a typical slope for the pump curve is negative 20m/(m3/s) and a typical high flow rate is 125% of rated flow. The flow rate of the high flow test point is therefore 9.590m3/s. Using this flow rate and the assumed slope of the pump curve, a high flow test point head is determined to be 66.35m. The heads of the two test points, 114.3m and 66.35m, are now be converted to pressures of 1143.0kPa and 663.5kPa, for use as necessary. These are the DP’s required by the orifices to achieve the two test points. Normally, other test loop piping losses would be considered, but for the purposes of this report, these additional piping losses are considered negligible. This method also provides conservative input to structural analyses. 3.2 Sizing of Orifice 1 Sizing of the first orifice which will be installed to achieve both test points will be based on the requirement to provide a DP of 663.5kPa. From this point forward, it will be designated as Orifice 1. To minimize constriction of the flow, a sharp edged orifice will 9 be used as opposed to an orifice with a beveled or rounded leading edge. Further, there are many good correlations to choose from for predicting the resistance of sharp edged orifices. Erosion of the sharp edge over time should not be a concern as coolant water that is pumped by RCP’s is extremely well controlled with no dissolved gases or suspended solids and run time for testing is relatively low. The correlation for “thick-edged orifice in a straight tube” from [6] is used for sizing of Orifice 1. “Thick-edged” is defined as l/Dh > 0.015, where l is the thickness of the orifice and Dh is the inner diameter of the orifice. Considering the large volume flow going through the orifice, a thick-edged orifice will be required for structural integrity. The correlation used to determine the inner diameter of Orifice 1 s shown below, all from Reference [6]. The corresponding figure from Reference [6] is also shown below in Figure 5. Figure 5: Diagram of Thick-Edged Orifice [6] 10 ∆𝑝 𝜌𝑤1 𝐹 0.75 = [0.5 (1 − 0) 2 ⁄2 𝐹 1 𝐹 1.375 + 𝜏 (1 − 0) 𝐹 1 𝐹 2 𝑙 𝐹 2 + (1 − 0) + 𝜆 ] ( 1) 𝐹 𝐷 𝐹 1 ℎ [6] 0 Where: 𝜏 = (2.4 − 𝑙) × 10−𝜑(𝑙)̅ −𝜑(𝑙 )̅ = 0.25 + 0.535𝑙 −8⁄(0.05 + 𝑙 −8 ) Δp = pressure difference (Pa) ρ = density of fluid (kg/m3) w1 = stream velocity of fluid (m/s), expressed as flow (m3/s) / orifice flow area (m2) F0 = flow area of orifice (m2) F1 = flow area of upstream and downstream piping (m2) λ = friction factor inside orifice inner diameter (unitless) ι = thickness of orifice (m) Dh = hydraulic diameter of the orifice (m) To size Orifice 1 using this correlation, the parameter F0 is solved for. To determine τ, the thickness of Orifice 1 (ι) must be assumed. The appropriateness of this assumption must be included in the conclusion from the structural analyses. For the purposes of the calculations, the thickness of the orifices is assumed to be 0.05m. It is desired to keep the orifice as thin as possible to reduce material and machining costs and for ease of installation, but not so thin as to cause concern for structural integrity of the orifices. To determine the friction factor (λ), an absolute pipe roughness from Reference [8] is used. The value used is for “Commercial Steel Pipe” and is 0.00015ft (4.572 X 10-5m). When this is divided this by the hydraulic diameter (Dh) a Moody Chart can be used to determine the friction factor if fully turbulent flow is assumed. Assuming fully turbulent flow is reasonable considering the very large volumetric flows. Other input parameters include the differential pressure (Δp) and the volumetric flow rate, which are defined as 663.5kPa and 9.59m3/s, respectively, in Section 3.1. Density of the water (ρ) is also required, which for the elevated temperature of 300°C, is 11 714kg/m3 from Reference [9]. Flow area of the upstream and downstream piping (F1) is also an input parameter and is defined as 0.785m2 [10]. When all of these inputs are used, F0 is determined to be 0.2347m2, which corresponds to an inside diameter of 0.547m for Orifice 1. Now that the orifice has been sized, the Reynolds Number and the ι/Dh must be checked as the correlation used requires the Reynolds Number to be greater than 103 and the ι/Dh to be greater than 0.015. The Reynolds Number is calculated below, where the kinematic viscosity (ν) of the water is 1.218 X 10-7 m2/s for the elevated temperature of 300°C. 𝑅𝑒 = 𝑄 (𝐹 ) 𝐷ℎ 0 𝜈 = 9.59 (0.2347) 0.547 1.218 × 10−7 = 1.834 × 108 Where: Re = reynold’s number (unitless) Q = pump flow (m3/s) ν = kinematic viscosity (m2/s) The Reynolds Number calculated is acceptable for the correlation that was used. In addition, the assumption of fully turbulent flow for use of the Moody Chart to determine the friction factor is validated. The ι/Dh is calculated to be 0.0915, which is greater than the required 0.015. As a result, all conditions to use the correlation for the “Thick-edged Orifice” from Reference [6] are satisfied. 3.3 Sizing of Orifice 2 Orifice 2 is used in conjunction with Orifice 1 to provide additional hydraulic resistance to achieve the low flow point. Orifice 2 is sized using the same methodology and correlation that was used for Orifice 1. The only input parameters that are changed are the volumetric flow through the orifices and required Δp. As defined in Section 3.1, the 12 flow rate through the orifices is 7.672m3/s and the total required Δp across the two orifices is 1143.0kPa for the low flow point. According to the correlation in Section 3.2, the Δp of the orifice is dependent on the flow rate. As a result, the Δp for Orifice 1 must first be recalculated for the low flow point. Using the flow area for Orifice 1 that was calculated in Section 3.2 and the low flow rate of 7.672m3/s, the Δp of Orifice 1 at the low flow point is calculated to be 266,565kPa. With this, the required Δp of Orifice 2 alone can finally be identified. 1,143,000𝑃𝑎 − 266,565𝑃𝑎 = 876,435𝑃𝑎 This means that Orifice 2 is required to have a significantly larger Δp than Orifice 1 and therefore, a much smaller inner diameter. Using this Δp and the low flow rate, the correlation from Section 3.2 is used again to solve for the flow area (F0) of Orifice 2. The flow area is calculated to be 0.1585m2, which corresponds to an inner diameter of 0.449m. The Reynolds Number for Orifice 1 is recalculated for the low flow point to be 𝑅𝑒1 = 𝑄 (𝐹 ) 𝐷ℎ 0 𝜈 = 7.672 (0.2347) 0.547 1.218 × 10−7 = 1.467 × 108 The Reynolds Number is then calculated for Orifice 2. 𝑅𝑒2 = 𝑄 (𝐹 ) 𝐷ℎ 0 𝜈 7.672 ( ) 0.449 = 0.1585 = 1.759 × 108 1.218 × 10−7 Both Reynolds Numbers make use of the correlation acceptable as they are both greater than 103. The ι/Dh for Orifice 1 does not change for the low flow point, but the Orifice 2 ι/Dh still must be checked. Using the assumed orifice thickness of 0.05m and the calculated hydraulic diameter of 0.449, the ι/Dh for Orifice 2 is calculated to be 0.111, which is greater than the required 0.015. As a result, use of the correlation defined in Section 3.2 is acceptable for Orifice 2 as well as Orifice 1. 13 3.4 Numerical Method for Calculation of Orifice Pressure Drop Generally, the analytical methods used in Sections 3.2 and 3.3 are considered to be very accurate as the equation used has been developed from decades of empirical data. However, for comparison, numerical methods for calculation of the Orifice DP are also explored in this project. Use of one method over the other may depend on which method provides the most conservative results. For this project, the orifice and flow condition that provide the highest pressure drop are analyzed numerically. This represents worst-case conditions for input into structural analysis later in the project. The orifice and flow condition that provide the highest pressure drop is Orifice 2, which is sized to provide a pressure drop of 876,435Pa to achieve the low flow condition of 7.672m3/s. This orifice and surrounding piping are modeled in the software COMSOL Multiphysics. Computational Fluid Dynamics (CFD) is performed with this geometry and flow condition and the resulting pressure drop is compared with the pressure drop that Orifice 2 was sized analytically to provide. To build the model in COMSOL, the same inputs are used that are identified in Section 3.2. The density that is used is 714kg/m, the viscosity is 8.97X10-5 Pa(s). The diameter of Orifice 2 is 0.449m. The lengths of the upstream and downstream piping were chosen to capture all upstream and downstream effects, yet minimize total number of elements so that computational time is minimized. The upstream pipe length was chosen to be 1.0m and the downstream pipe was selected to be 10m. The inlet velocity of the model is specified to be 9.773m/s, which corresponds to the volumetric flow for the low flow condition of 7.672m3/s for a 1.0m diameter pipe. Figure 6 below shows the geometry of the model. Since the model is axis-symetric, a 2-D model of half of the pipe and orifice is sufficient. 14 FLOW Orifice Axis of Symmetry Figure 6: Geometry of COMSOL Model Four different mesh sizes are used and their results are compared to justify that the smallest mesh size is indeed small enough to be able to accurately compare with the analytical results and potentially provide input values to the structural analysis of the orifice. The auto-mesh function of COMSOL is used for meshing. This auto-meshing creates appropriate mesh sizes and geometries at all locations within the model to capture all fluid behavior, but to minimize computation time. Cases were run for automesh sizes of “Extremely Coarse”, “Extra Coarse”, “Coarser” and “Coarse”, listed coarsest to finest. Figure 7 below shows an example of the auto-meshing. The figure shows the area around the geometry of the orifice. Orifice Figure 7: Auto-Meshing of COMSOL Model As expected, the meshing shown in Figure 7 is much finer around the edges of the orifice and along the pipe walls. This is required as the pressure and velocity gradients in these locations are large relative to other locations. All elements are triangular. 15 The results of all four mesh sizes are compared and show diminishing returns as the mesh size is decreased. The parameter that is compared between each case is the DP from the inlet to the outlet of the entire model. The results from all four mesh sizes are shown below in Table 1. The change between “Extremely Coarse” and “Extra Coarse” is (1.4262-1.6495)/1.4262 = 15.66%. The change between “Extra Coarse” and “Coarser” is 4.43% and the change between “Coarser” and “Coarse” is 0.18%. The conclusion is that either the “Coarser” or “Coarse” auto-mesh setting is sufficient. The results from the “Coarse” case are shown below. Table 1: COMSOL Mesh Comparison COMSOL Auto- Total Number of Calculated Orifice Mesh Size Elements DP (MPa) Extremely Coarse 3,988 1.4262 N/A Extra Coarse 6,916 1.6495 15.66 Coarser 13,443 1.5764 4.43 Coarse 21,099 1.5735 0.18 Change (%) According to Reference [11], numerical methods generally perform three major steps to solve a system. The first step is to perform integration of the governing equations over the control volume. The resulting integral equations are then converted to a system of algebraic equations. Finally, this system of algebraic equations is solved iteratively. This is the general method used by COMSOL to solve the orifice flow system that is described. Since this is a fluid flow system, the governing equations of the system include conservation of mass, the first law of thermodynamics and Newton’s second law [11]. When solving, certain assumptions may be made by the algorithm to simplify the problem and facilitate its solution. Figures 8 & 9 show the results of the COMSOL model. Figure 8 shows the velocity streamlines of the entire system, while Figure 9 shows a magnified view of the velocity 16 streamlines just downstream of the orifice. This area is referred to as the recirculation zone. FLOW Orifice Figure 8: Velocity Streamlines through COMSOL Model FLOW Orifice Recirculation Zone Figure 9: Magnified View of Recirculation Zone The velocity streamlines are typical for orifice flow. Because of the very high flow rate and Reynold’s number, the flow is very uniform through upstream of the orifice and downstream of the recirculation zone. The velocity boundary layer at the pipe wall is very small. Figures 8 & 9 also show that the orifice only affects the upstream velocity profile over a short distance, about 0.5m and that the downstream velocity profile (and pressure) is not fully recovered until about 5.0m downstream of the orifice. This proves that the upstream pipe length of 1.0m and the downstream pipe length of 10.0m are sufficient. This is true for all mesh sizes. Results of the COMSOL model can also be used to determine the minimum spacing between the two orifices when they are installed in series. It is important to have the velocity fully recovered from the first orifice before entering the second to avoid undesirable flow characteristics, which could affect flow measurements. Since Orifice 2 is the more constrictive orifice and the low flow condition is modeled, the length of the 17 velocity recirculation zone of 5.0m can be used as a minimum distance between the two orifices to avoid. Pressure contour lines from the “Coarse” mesh case are shown below in Figure 10. The range of pressures from the inlet of the upstream pipe to the outlet of the downstream pipe is shown on the right hand side of the figure. The majority of the pressure drop and recovery is shown in the view in Figure 10 and the pressure is relatively uniform both upstream and downstream of the orifice. Orifice Flow Figure 10: Pressure Contour Plot Figure 10 shows that the pressure gradients around the orifice are very large with a range of about 2 X 106 Pa. The area with the highest pressure gradients is the leading edge of the orifice. This shows the importance of a structural analysis of the orifice to ensure that the resulting stresses within the orifice plate are below yield stresses. 18 Figure 11 shows a plot of the pressure along the axis of symmetry of the model (meters). The pressures shown are relative to a downstream pipe outlet pressure of zero. The actual pressures depend on the pressure of the system, but only the difference in pressure is of interest for design and analysis of the orifice. Orifice Figure 11: Pressure Along Axis of Symmetry According to the results, pressure starts to decrease rapidly about 0.5m upstream of the orifice as a result of the increase in velocity. Some of the pressure is recovered by about 5.0m downstream of the orifice, but only about 6.5x105 Pa of the 2x106 Pa. As previously stated, the numerical method calculates the pressure drop across the orifice to be 1.5735MPa. This value is the maximum value shown in Figure 10, which is 19 the maximum pressure in the system, as opposed to only the magnified view. Since the pressures are such that the pressure value at the exit of the system, then the maximum pressure in the system represents the total pressure drop across the orifice. COMSOL assumes that there are no frictional losses at the pipe walls. These results can be compared directly with the results from the analytical method from Section 3.3. For the same geometry, flow rate and fluid properties, the two methods calculate very different pressure drops. As stated in Section 3.3, the orifice was sized using the analytical method to produce a pressure drop of 0.8764MPa. The difference between the results is (1.5735-0.8764)/0.8764 = 0.795 or 79.5% of the analytical results. The difference of 79.5% between the analytical and numerical results is much larger than expected. This difference is attributed to the differences in equations and processes used for calculation of the orifice pressure drop. It is thought that the analytical method may provide the more accurate results as the equations are based on large amounts of empirical data. However, in this case, the numerical method provides conservative input to structural analyses that will be performed in Section 3.5. 3.5 Static Structural Analysis of Orifice For the static structural analysis, the software ANSYS Workbench is used to determine conservative stresses and the stress distribution throughout the geometry. This is important to ensure that the material yield strength is not exceeded and will confirm that the assumed orifice thickness and material is appropriate. The geometry of the ANSYS Workbench model is identical to the orifice whose pressure drop was determined in Sections 3.4. The outer diameter is 1.0m, the inner diameter is 0.449m and the thickness is 0.05m. This geometry is created by extruding two concentric circles. A one-quarter slice is used for analysis purposes to reduce the number of mesh elements required for solving. This may be done considering the symmetrical geometry of the orifice. A one-quarter slice is chosen as the meshing for a 20 one-quarter slice is simpler than it would be for a smaller slice. The geometry is shown below in Figure 12. Figure 12: ANSYS Workbench Geometry Different from the method used to mesh the COMSOL model, the ANSYS auto-meshing feature is not used. The ANSYS auto-meshing feature is not conducive to radially symmetric geometries. To mesh the geometry, the model is manually divided so that the elements along the edges are all uniform and all elements are of similar shape. The entire geometry is divided along 3 edges. The number of divisions along these edges controls the total number and size of the elements. The pattern of the meshing with large elements is shown below in Figure 13. 21 Figure 13: ANSYS Workbench Model Meshing Similar to the method used in COMSOL in Section 3.4, numerous cases are run with different number of elements to show diminishing returns. The maximum stress intensity is compared between each case and the results are shown in Table 2. 22 Table 2: ANSYS Mesh Comparison Total Number of Maximum Stress Elements Intensity (MPa) Change (%) 1 1,250 82.533 N/A 2 4,480 92.299 11.8 3 10,584 100.82 9.2 4 21,315 108.73 7.8 5 43,660 117.12 7.7 6 81,000 124.31 6.1 ANSYS Mesh Case ANSYS Mesh Case 6 is considered adequate considering the 6.1% change in maximum stress intensity when 37,340 elements are added. Increasing the number of elements significantly to more than 81,000 is considered not worth the extra computational time. To obtain conservative stresses, conservative forces (or pressures) must be applied to the model. One conservative method for defining the force would be to apply the entire head of the pump at the low flow condition to the front face of the orifice plate. This would be a value of 1.143MPa, which was determined in Section 3.1. If only analytical methods were used, this would be the most conservative approach. However, in this case, a numerical approach was also used. To use the results from the numerical method, the pressure was plotted along the face of the orifice in the COMSOL model. This pressure is shown below in Figure 14. 23 Figure 14: COMSOL Pressure Plot Along Orifice Face According to the plot in Figure 14, the pressure increases going from the inner diameter of the orifice to the outer diameter. From about half-way between the inner and outer diameter to the outer diameter, the pressure is a constant 1.6MPa. conservative than the value of 1.143MPa discussed above. This is more For simplicity and conservatism, the pressure of 1.6MPa is applied to the entire orifice face in the ANSYS model. To constrain the model prior to solving, the outer edge of the orifice is a categorized as a “Fixed Support”. This means that no translation or rotation of this surface is allowed. This is identified as “Surface C” in Figure 15, below. This support simulates the orifice being flanged into the surrounding piping. The cuts that are made to simplify the geometry for symmetry are defined as “Frictionless Supports”. This allows frictionless motion, but still provides support as if rest of the orifice is present. These surfaces are 24 identified as “Surface B” in Figure 15 below. Finally, the red surface in Figure 15 is the front face of the orifice where the pressure is applied uniformly. The pressure identified as “Pressure A” is shown to be 1.6MPa. Surface C Pressure A Surface B Figure 15: Setup of ANSYS Model The numerical solution of this model follows a similar method to that described in Section 3.4. However, since this is a static structural problem, different governing equations apply. The equations used depend on the geometry and loading/constraining of the model. Solution of the model provides the deformation and the stress intensity. These are shown below in Figures 16 and 17, respectively. As expected, the axial deformation increases as the inner diameter of the orifice is approached. This is because the orifice is fixed at only one end, creating a cantilever-type effect. exaggerated deformation. 25 Figure 16 provides an Figure 16: Deformation of ANSYS Model Figure 17: Stress Intensity of ANSYS Model 26 The maximum stress intensity is the main parameter of interest from the ANSYS model. Figure 17 shows that this maximum occurs along the outer diameter and outermost edges of the orifice. This is expected as this is the location that has the highest stress moment due to the cantilever-type effect of the orifice. The maximum stress intensity is calculated to be 124.31MPa. To determine if this stress intensity value is acceptable, it must be compared with the yield strength of the material. The assumed material for the ANSYS model is stainless steel. Stainless steel is assumed instead of carbon steel because the water that is run through the RCPs must be very clean and should not have any harmful chemicals or solid particles. Chemicals and solid particles can cause damage to the very sensitive hydraulics, bearings and seals. According to Reference [12], the yield strength of Type 304 Stainless Steel in a plate form at a conservative temperature of 600°F (316°C) is 12.6ksi (84.805MPa). When the results of the ANSYS model are compared to the yield strength of Type 304 Stainless Steel, the maximum stress intensity calculated is well above the yield strength. This is due to the high operating temperate at which point the yield strength is much lower. To correct for this, the orifice is geometry in ANSYS is extruded to be twice as thick (0.1m) to reduce this maximum stress intensity. The total number of mesh elements is kept around 80,000 due to computational limitations. Since the volume is doubled, the element size is comparable to the results for Mesh Case 5 from Table 2, which is considered to be accurate enough for the purposes of this analysis. The resulting maximum stress intensity value is calculated by ANSYS to be 42.513MPa. This provides a safety factor of nearly 2, which is considered acceptable for this design. Another option would have been to change the material to a material with a higher yield strength at the testing temperature. Doubling the thickness is expected to have a very minor impact on orifice pressure drop and sizing calculations and thus resizing is not necessary. 27 3.6 Modal Analysis of Orifices The modal analysis is the final step to the project. The purpose of this analysis is to determine the natural frequencies of the orifices. The supports and hydraulic forces must be considered. ANSYS Workbench is also used for the modal analysis so that the same geometry and meshing can be used. Further, the supports and pre-stresses that are calculated in the static structural analysis as a result of the hydraulic forces can be easily applied to the geometry. Damping of the water itself and the reduction in hydraulic force near the inner diameter of the orifice (shown in Figure 14) is considered negligible. The first 6 natural frequencies and modes are calculated. A modal analysis is performed on both orifices as there is not a conservative condition. To avoid undesired resonance conditions, the natural frequencies for either orifice cannot be the same frequency as the hydraulic pressure pulsations generated by the pump. The number of mesh elements used for both orifices is 8960. Due to computational limitations, this is the highest number of mesh elements that could be used. If the results show that the orifice natural frequencies are close to the pump hydraulic pressure pulsation frequencies, a finer mesh is recommended. The results of the modal analyses are shown in Table 3. All mode shapes are shown exaggerated in Appendix A. 28 Table 3: Orifice Natural Frequencies Mode Orifice 1 Frequency (Hz) Orifice 2 Frequency (Hz) 1 1740.4 1316.4 2 2458.8 2334.4 3 4133.1 4309.1 4 5609.7 4812.1 5 6161.1 4840.9 6 6271.4 5431.0 The numerical solution of this model follows a similar method to that described in Section 3.4. However, since this is a dynamic structural problem, different governing equations apply. The equations used depend on the geometry and loading/constraining of the model. As shown in Table 3, the minimum natural frequency between the two orifices is 1316.4Hz. As expected, the natural frequencies of Orifice 2 are lower than those of Orifice 1. This is due to the basic equation shown below, which tells us that as mass is increased, the natural frequency is decreased. Since the inner diameter of Orifice 2 is smaller than the inner diameter of Orifice 1, Orifice 2 has the higher mass. 𝜔𝑛 = √ 𝑘 𝑚 Where: ωn = natural frequency (rad/s) k = spring constant for natural frequency (unitless) m = mass (kg) 29 [13] The lower mode shapes (1-3) are very similar between the two orifices since their geometry is similar. The higher mode shapes (4-6) show some differences between the two orifices. A pump’s hydraulic pressure pulsation frequency is generated by the rotating impeller blades passing by the stationary diffuser vanes. Considering, the frequency at which an impeller blade passes a diffuser vane will be the pump pressure pulsation frequency. This is referred to as the pump blade passing frequency (BPF). The pump speed and the number of impeller blades determine the frequency. The impeller described by Reference [7] is a six bladed impeller that rotates at 1190rpm. 1190rpm X 6 blades = 7,140 blade passings per minute 7,140 / 60 seconds per minute = 119Hz The pump BPF is calculated to be 119Hz. When compared to the results in Table 3, the pump BPF is significantly lower than the minimum orifice natural frequency of 1316.4Hz. A factor of safety of nearly 11 is achieved. With such a high factor of safety, further analysis with finer meshing is not required. Finally, this means that the orifices will not be excited by the pump pressure pulsations and that the orifice design is sufficient. 30 4. Conclusions The results of this project have proved to be intriguing and thought provoking. From Section 3.1, it was determined that the pressure drops required of the orifices are as large as 1.143MPa (165.8psi). This emphasizes the need for two orifices rather than one as the significant constrictions to the flow would be minimized for orifice structural concerns and for RCP NPSH testing. Sections 3.2 and 3.3 perform the sizing of the orifices using the analytical method, which is generally thought to be an accurate method as the equations are derived from decades of empirical data. The results show that Orifice 2 has the smaller inner diameter and greatest pressure drop. The maximum pressure drop is calculated to be 876,435Pa and occurs during the low flow condition of 7.672m3/s. This is the most limiting condition from a structural perspective and is used for input into the structural analyses. Results from the numerical method for calculation of the orifice pressure drop were 79.5% greater than the analytical method. This is considered to be a very poor correlation between the two methods. The difference is attributed to the differences in basic equations and how the equations were developed. The most conservative method should be used for structural input and the method believed to be most accurate should be used for sizing purposes. Another conclusion that can be drawn from the COMSOL results is the minimum distance between the two orifices. It is desirable to have the velocity fully recovered from the first orifice before entering the second to avoid undesirable flow characteristics, which could affect flow measurements. Since Orifice 2 is the more constrictive orifice and the low flow condition is modeled, the length of the velocity recirculation zone of 5.0m can be used as a minimum distance between the two orifices to avoid. From the structural analysis, the results showed that the maximum stress exceeded the yield strength of Type 304 Stainless Steel for the orifice thickness of 0.05m. An orifice of this thickness would be expected to plastically deform at the outer edges of the outer 31 diameter of Orifice 2 at the low flow condition. When the thickness was increased to 0.1m, the results were found to be acceptable with a factor of safety of 2. It is concluded that increasing the thickness of the orifice plate is a simple way to decrease the maximum stress intensity. This is preferable to using a material with a higher yield strength because Type 304 Stainless Steel is readily available and is most likely cheaper than higher strength materials. From the results of the modal analysis, it is concluded that the natural frequencies are far above the pump pressure pulsation frequency. As a result, excitation of the orifices by the pump pressure pulsations is not of concern. Future studies should attempt to get a better correlation between analytical and numerical pressure drop calculation results. A better correlation could result in more accurate (less conservative) input to the structural analysis. This could result in a thinner orifice plate, saving cost of material and making installation in & removal from the test loop easier. Future studies may also improve the meshing of the orifice for both the static and structural analyses. A computer system with more memory would allow solving of the geometry with more mesh elements. A smaller symmetrical section of the orifice could also be used to reduce computational efforts. Finally, now that it is known where the highest stress gradients are in the orifice, the mesh efficiency could be improved to have smaller mesh elements near the orifice outer diameter and larger mesh elements near the orifice inner diameter. 32 5. References 1) “Pressurized Water Reactor (PWR) Systems”, Nuclear Regulatory Commission website http://www.nrc.gov/reading-rm/basic-ref/teachers/04.pdf 2) “Pressurized Water Reactor (PWR)” Copyright © 1996-2006, The Virtual Nuclear Tourist, December 19, 2005. http://www.nucleartourist.com/type/pwr.htm 3) “Damages by Cavitation” Chemical & Process Technology, May 7, 2008. http://webwormcpt.blogspot.com/2008/05/damages-by-cavitation.html 4) “Fundamentals of Fluid Mechanics”, Fifth Edition by Munson, Young and Okiishi. Copyright © 2006 by John Wiley & Sons, Inc. 5) “Diffuser” © 2011 Construction, Mechanical Engineering, Automotive News Tips http://constructionmechanical-engineering.blogspot.com/2010/04/diffuser.html 6) “Handbook of Hydraulic Resistance” Third Edition, by Idelchick, Jaico Publishing House © CRC Press, Inc. & © Begell House Inc. First Jaico Impression: 2003, Sixth Jaico Impression: 2008 7) Doosan Heavy Industries and Construction – Business Sector, “APR1400 Class Reactor Coolant Pump,” http://www.doosan.com/doosanheavybiz/en/services/power/power_plant/reactor_coolant_p umps.page 8) “Flow of Fluids Through Valves, Fittings, and Pipe – Technical Paper 410” © 1976 – Crane Co. 9) “Water – Thermal Properties” The Engineering Toolbox. http://www.engineeringtoolbox.com/water-thermal-properties-d_162.html 10) “Reactor Cooling Systems… More” Copyright © 1996-2006, The Virtual Nuclear Tourist, January 6, 2006. http://www.nucleartourist.com/systems/rcs2.htm 11) “An Introduction to Computational Fluid Dynamics – The Finite Volume Method” Second Edition, H K Versteeg & W Malalasekera. © 2007 by Pearson Education Limited. 12) 2007 ASME Boiler & Pressure Vessel Code Section II, Part D “Properties – Materials”, © 2007 by The American Society of Mechanical Engineers. 13) “Engineering Vibration” Section Edition, Daniel J. Inman. ©2001 by Prentice-Hall, Inc. 33 Appendix A: Orifice Mode Shapes Mode 1 – Orifice 1 Mode 1 – Orifice 2 34 Mode 2 – Orifice 1 Mode 2 – Orifice 2 35 Mode 3 – Orifice 1 Mode 3 – Orifice 2 36 Mode 4 – Orifice1 Mode 4 – Orifice 2 37 Mode 5 – Orifice 1 Mode 5 – Orifice 2 38 Mode 6 – Orifice 1 Mode 6 – Orifice 2 39