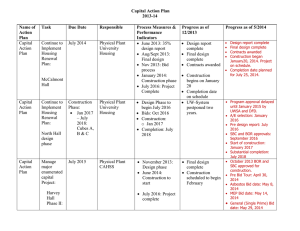

Addendum 1 - Specifications

advertisement

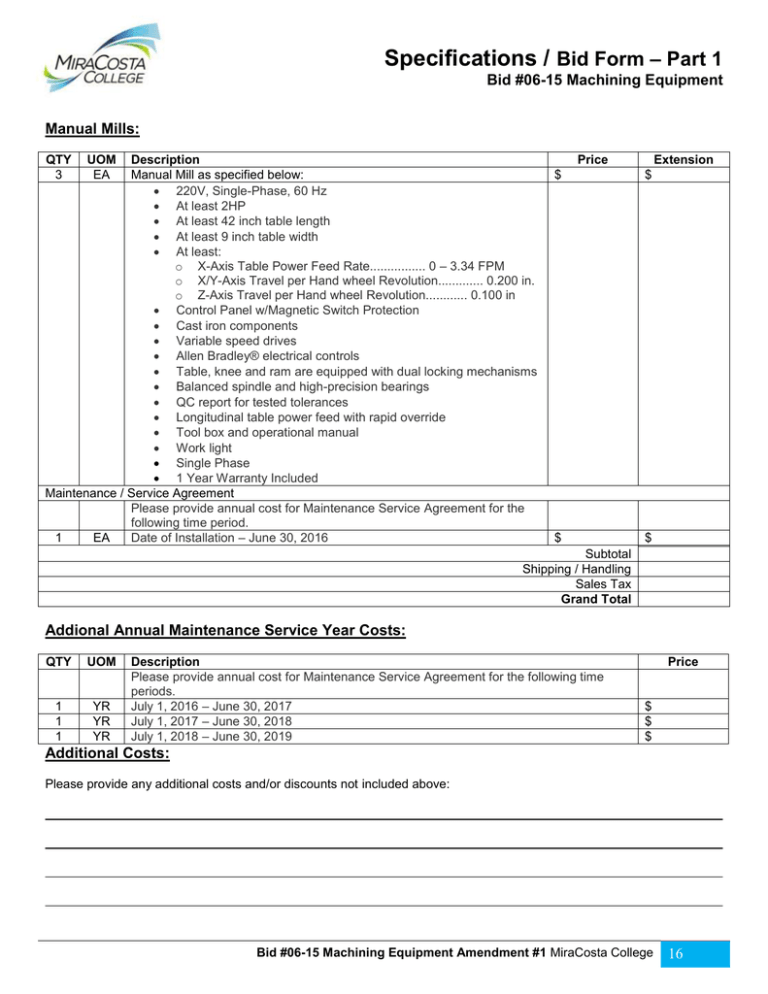

Specifications / Bid Form – Part 1 Bid #06-15 Machining Equipment Manual Mills: QTY 3 UOM EA Description Manual Mill as specified below: 220V, Single-Phase, 60 Hz At least 2HP At least 42 inch table length At least 9 inch table width At least: o X-Axis Table Power Feed Rate................ 0 – 3.34 FPM o X/Y-Axis Travel per Hand wheel Revolution............. 0.200 in. o Z-Axis Travel per Hand wheel Revolution............ 0.100 in Control Panel w/Magnetic Switch Protection Cast iron components Variable speed drives Allen Bradley® electrical controls Table, knee and ram are equipped with dual locking mechanisms Balanced spindle and high-precision bearings QC report for tested tolerances Longitudinal table power feed with rapid override Tool box and operational manual Work light Single Phase 1 Year Warranty Included Maintenance / Service Agreement Please provide annual cost for Maintenance Service Agreement for the following time period. 1 EA Date of Installation – June 30, 2016 Price Extension $ $ $ $ Subtotal Shipping / Handling Sales Tax Grand Total Addional Annual Maintenance Service Year Costs: QTY UOM 1 1 1 YR YR YR Description Please provide annual cost for Maintenance Service Agreement for the following time periods. July 1, 2016 – June 30, 2017 July 1, 2017 – June 30, 2018 July 1, 2018 – June 30, 2019 Price $ $ $ Additional Costs: Please provide any additional costs and/or discounts not included above: Bid #06-15 Machining Equipment Amendment #1 MiraCosta College 16 Manual Lathes: QTY 5 UOM EA Description Manual Lathes as specified below: At Least 13 Swing over bed x 40 center length At least 2 HP 220 Volt Easy Change Chuck Mounts Uses Standard ½” tooling Heavy Cast Bed with Harden Ways Gear Drive Power Train Powerfeed on Leadscrew and Crossfeed Offset Tailstock Threading Dial and Half Nut Single Phase Steady Rest Foot break Coolant system Work light Lathe stand included in bid 1 Year Warranty Included Maintenance / Service Agreement Please provide annual cost for Maintenance Service Agreement for the following time periods. 1 EA Date of Installation – June 30, 2016 Price Extension $ $ $ $ Subtotal Shipping / Handling Sales Tax Grand Total Addional Annual Maintenance Service Year Costs: QTY UOM 1 1 1 YR YR YR Description Please provide annual cost for Maintenance Service Agreement for the following time periods. July 1, 2016 – June 30, 2017 July 1, 2017 – June 30, 2018 July 1, 2018 – June 30, 2019 Price $ $ $ Additional Costs: Please provide any additional costs and/or discounts not included above: Bid #06-15 Machining Equipment Amendment #1 MiraCosta College 17 Automated Surface Grinder: QTY 1 UOM EA Description Automated Surface Grinder as specified below: 10”x20” working capacity; 3-axis automatic movement with incremental downfeed and electronic auto-crossfeed Roller ball on linear table ways Double V precision turcite saddle ways High column extra rigid H-frame design with 10.4”x21.4” Working Capacity Centralized automatic lubrication system Safety 24V control circuit power At least 3 HP At least 3500 RPM spindle speed At least 8” x 1” x 1-1/4” Grinding wheel Leveling bolts and pads Work Light attached 1 Year Warranty Included Maintenance / Service Agreement Please provide annual cost for Maintenance Service Agreement for the following time periods. 1 EA Date of Installation – June 30, 2016 Price Extension $ $ $ $ Subtotal Shipping / Handling Sales Tax Grand Total Addional Annual Maintenance Service Year Costs: QTY UOM 1 1 1 YR YR YR Description Please provide annual cost for Maintenance Service Agreement for the following time periods. July 1, 2016 – June 30, 2017 July 1, 2017 – June 30, 2018 July 1, 2018 – June 30, 2019 Price $ $ $ Additional Costs: Please provide any additional costs and/or discounts not included above: Bid #06-15 Machining Equipment Amendment #1 MiraCosta College 18 Laser Cutter/Engraver: QTY 1 UOM EA Description Laser Cutter / Engraver as specified below: Work area of at least 24" x 12" (609 x 305 mm) At least 3” focal length Cutting thickness to at least 5” Solid State air cooled laser Multiple file storage up to at least 64MB Compatible with Windows XP/Vista 7 & 8 Laser beam visual reference guide or Auto-focus feature High Speed continuous loop motion control systems Compatible with both metal and plastics Inline lighting Comes with an integrated air compressor Ability to print directly from computer to the laser using most graphic design, serializing, or CAD software package Wireless networking capability Ability to engrave or mark multiple parts at one time Tempered Glass Door Laser cutter stand included in bid Ability to etch, polish and anneal surfaces Factory Training option through either clinics, virtual training, or individualized instruction for our teachers 1 Year Warranty Included Maintenance / Service Agreement Please provide annual cost for Maintenance Service Agreement for the following time periods. 1 EA Date of Installation – June 30, 2016 Price Extension $ $ $ $ Subtotal Shipping / Handling Sales Tax Grand Total . Addional Annual Maintenance Service Year Costs: QTY UOM 1 1 1 YR YR YR Description Please provide annual cost for Maintenance Service Agreement for the following time periods. July 1, 2016 – June 30, 2017 July 1, 2017 – June 30, 2018 July 1, 2018 – June 30, 2019 Price $ $ $ Additional Costs: Please provide any additional costs and/or discounts not included above: Bid #06-15 Machining Equipment Amendment #1 MiraCosta College 19 Specifications / Bid Form – Part 2 Bid #06-15 Machining Equipment Line 1 2 3 QTY 2 UOM EA Description CNC Lathe as specified below: Approximately 77” (h) x 80” (w) x 68” (d) in size At least 16” x 29” cutting capacity At least 2,000 rpm spindle Approximate swing diameter of 16” 7.5 hp vector drive 2.31” spindle bore Belt drive 8” manual 3-jaw scroll chuck with mount Spindle check guard Manual tailstock and quill Coolant pump kit with at least 24-gallon tank Rigid tapping Quick-change tool post, at least 2 positions. Boring bar holder and t-nut Chip enclosure kit Intuitive programming system with at least 1 MB program memory, USB port, and 15” color LCD monitor Maintenance / Service Agreement 1 EA Please provide annual cost for Maintenance Service Agreement for the following time period: Date of Installation – June 30, 2016 2 EA CNC Mills as specified below: Approximately 105” (h) x 96” (w) x 82” (d) in size At least 30” x 12” x 16” cutting capacity At least 6,000 rpm spindle 40 taper 7.5 hp vector drive Full enclosure 10 station automatic tool changer 4th-Axis drive and wiring Chip conveyor, auger style Rigid tapping Wireless intuitive probing system (Renishaw or similar) 5-gallon flood coolant system Intuitive programming system with at least 1 MB program memory, USB port, and 15” color LCD monitor Maintenance / Service Agreement Please provide annual cost for Maintenance Service Agreement for the following time periods. 1 EA Date of Installation – June 30, 2016 2 EA CNC Simulators as specified below: Mill and lathe simulation LCD display USB port Price Extension $ $ $ $ $ $ $ $ $ $ Subtotal Shipping / Handling Sales Tax Grand Total Bid #06-15 Machining Equipment Amendment #1 MiraCosta College 20 Addional Annual Maintenance Service Year Costs: QTY UOM 1 1 1 YR YR YR Description Please provide annual cost for Maintenance Service Agreement for the following time periods. July 1, 2016 – June 30, 2017 July 1, 2017 – June 30, 2018 July 1, 2018 – June 30, 2019 Price $ $ $ Additional Costs: Please provide any additional costs and/or discounts not included above: Bid Certification: I, , the of the firm, hereby certify under penalty of perjury under the laws of the State of California, that all of the information submitted by the bidder in connection with this bidl and all of the representations made herein are true and correct and that the bidder named below is legally authorized to enter into contracts with the District. Executed on this day of , 20 at County, California. Name of Firm Address Printed Name of Responsible Financial Agent City, State, Zip Authorized Agent Signature Phone E-mail address Fax Federal Tax ID Bid #06-15 Machining Equipment Amendment #1 MiraCosta College 21