article_ICNS_final_II2001.DOC

advertisement

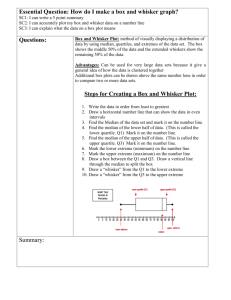

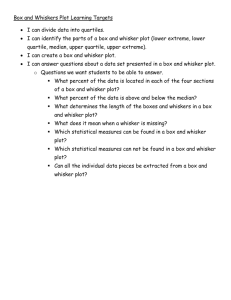

Neutron diffraction determination of residual stress in 6061Al-15 vol%SiCw composites with different whisker orientation R.Fernández1, G.Bruno2, A.Borrego1, G.González-Doncel1, A.Pyzalla2 1 Dept. of Physical Metallurgy, Centro Nacional de Investigaciones Metalúrgicas (CENIM), C.S.I.C. Av. de Gregorio del Amo 8, E-28040 Madrid, Spain 2 Hahn-Meitner Institut, Glienicker Str.100, D-14109 Berlin, Germany PACS: 81.05.N, 61.12, 07.10.P Abstract The determination of residual stresses, RS, in 6061Al-15vol%SiCw composites was carried out to correlate them with whisker orientation, distribution and aspect ratio. The composites were obtained by a powder metallurgical, PM, route and consolidated by extrusion at four different temperatures, Text. This is the main parameter affecting the whisker orientation/ distribution; an increase in T ext leads to an increasing whisker alignment with extrusion axis. The results of the sin2 plots account for a non-hydrostatic stress state in all composites. This is expected because of the deviatoric component of the RS tensor generated by the whisker geometry. The RS can explain the Strength Differential Effect, SDE, observed in uniaxial testing (tensile vs. compressive behaviour) of these composites. Introduction Among the different proposed strengthening mechanisms related to the addition of ceramic reinforcement to a monolithic metallic material in a Metal Matrix Composite, MMC, [1], RS play a very important role. For example the SDE, which has been observed by several authors [2], cannot be explained by means of well-known mechanisms like load transfer (shear-lag) and dislocation enhancement. The SDE, however, has been related to RS [3]. The present work has been focused on the effect of whisker orientation on RS in MMCs. 1. Materials and Experimental Procedures The investigated composites were prepared by a powder metallurgical route from powder of AA6061 and 15%vol -SiC single crystal whiskers. Four different composite materials extruded at different temperatures were obtained, Table 1, [4]. Unreinforced AA6061 was also prepared. In short, it was seen in [4] that: (i) The whisker length is similar for all materials (about 3.4 0.1m); (ii) The volume fraction of the <111> and <100> matrix fibre texture components developed during extrusion, depends on Textr; (iii) The fraction of whisker aligned with the extrusion axis (≤15º) increases with Textr. Material Textr Fv<111> Fv<100> Fv of aligned Code (°C) ≤15º (%) ≤15º (%) whiskers (%) C08 525 46 20 ----C32 300 28 14 26 C34 359 27 14 25 C38 498 50 16 31 C45 534 37 18 31 Table 1- Processing and microstructural parameters of the investigated materials. The grain size and the whisker length are very similar in all composite materials. The sin2 method [5] was used to obtain RS by neutron diffraction, ND, fig.1. Here, the lattice spacing (or the strain) is plotted against sin2 Measurements were performed on the E3 diffractometer at HMI, Berlin, using a wavelength = 1.37 Å and a gauge volume of 222 mm3 on cylinders, 6.5 mm diameter and 13 mm height. The Al- and SiC-(311) planes were used because they are low index and low texture planes and provide for a good approximation to the isotropic macroscopic elastic properties; i.e. RS are directly comparable to mechanical behaviour. The RS in the materials were studied in a peak-aged condition [6]. Texture analysis by means of x-rays shows that in the reinforcement a large fraction of randomly aligned particles is present and the <111> fibre texture present is not so strong. However, a pronounced <111> + <100> fibre texture was found in the matrix. For this reason only a few directions are suitable for RS analysis. In fact, a good signal-to noise ratio in ND could be measured only on few angles, which were chosen to perform the sin2 scan. For calculation of strain, the matrix C08 (unreinforced) was taken as reference, unstressed material. Because of the axisymmetry of the extrusion process, the stress tensor components rad and hoop are equal. = 0° ax = 90° rad Incident Beam Scattering Plane Sample Extrusion Axis Fig.1- Description of the geometry of the ND experiment. (ranging from 0° to 90°) is the angle between the scattering vector Q and the sample axis (extrusion direction). The sample is tilted within the scattering plane, thus using the so-called -method. The axial and radial sample directions correspond to the angles = 0° and = 90°. Q Detector 2 2. Results and Discussion The results of the sin2 plot measurements, figs. 2, indicate that strains (stresses) are tensile in the matrix and compressive in the SiC phase and that, in general, there is a non hydrostatic RS state in all reinforced materials. This non hydrostatic stress state is, however, expected in a whisker reinforced MMC because of the deviatoric component = ax - hydr of the RS tensor generated by the whisker geometry itself [7]. The latter is associated to the difference between the tension and compression behaviour, SD. No clear effect of whisker distribution/orientation, specific of each composite, is appreciated, as the slope of the curves, and thus the RS, are very similar. 800 200 (a) Al Phase 0 400 C32 200 C34 C38 C45 0 -200 0 0.2 0.4 2 sin 0.6 0.8 1 (strain) (strain) 600 (b) C38 C45 C32 C34 -200 -400 -600 SiC Phase -800 0 0.2 0.4 0.6 0.8 1 2 sin Fig.2- strain, , vs sin2 curves for all the investigated samples. (a) matrix, (b) reinforcement. The difference between the strains measured at = 0° and = 90° is proportional to the RS that causes the SDE (see table 2). The hydrostatic stress contribution in the SiC may be related to the choice of the unstrained material. RS are generated in the quenching process from the solid solution process (520ºC) prior to the ageing treatment, and the extrusion temperature (when lower than the solid solution mixing temperature) can be supposed to have little influence on RS. The tension and compression strength differences, SD/2 are in good agreement (Table 2) with the ND measurements and calculations with a modified Eshelby model [8], which takes into account the orientation distributions of whiskers. The anomaly shown by the C45 material can be associated to the inhomogeneous whisker distribution observed. Mat. SD/2 Al Eshelby SiC ’SiC Code (MPa) (MPa) (MPa) (MPa) (MPa) C08 0 0 C32 10 3 8 -43 -14 C34 9 11 9 -23 -62 C38 12 14 14 -69 -78 C45 26 15 12(29) -47 -87 Table 2- Comparison between calculated and measured stresses. are the measured differences between the axial and the hydrostatic RS in both phases. Eshelby is the RS in the matrix calculated with a modified Eshelby model. Typical errors are: 7 MPa for the matrix and 30 MPa for the SiC. ’SiC is the calculated RS in the reinforcement using the equilibrium condition between both phases. This material developed a stripe like structure. If we take into account that only some of the regions are effectively reinforced, the Eshelby value mirrors the measured SD for which case the value in parenthesis, table 2, is obtained. The RS from Neutron Diffraction give an average value, which agrees with an homogeneous Eshelby model. 3. Acknowledgement HMI, Berlin, Germany, in the frame of the Access to Research Infrastructures of the EC (contract n.o ERBFMGECT950060) and Projects: MAT97-1059-C02-01 from CICYT and 07N/0066/98 from Consejería de Educación y Cultura of CAM, Spain. 4. References [1]- T.Christman, A.Neeldman, S.Suresh: Acta metall. 37, 3029 (1989) [2]- R.S.Arsenault, S.B.Wu: Mater. Sci. Eng. 96, 77 (1987) [3]- R.S.Arsenault, M.Taya: Acta metall. 35, 651 (1987) [4]- A.Borrego, R.Fernández, M.C.Cristina, J.Ibáñez, G.González-Doncel: submitted to Textures and Microstructures [5]- H.Dölle, V.Hauk: Z.Metallkde 69, 410 (1978) [6]- A.Borrego, J.Ibáñez, V.López, M.Lieblich, G.González-Doncel: Scripta mater. 34, 471 (1996) [7]- K.Maeda, K.Wakashima: Scripta mater. 36, 335 (1997) [8]- P.J.Withers, W.M.Stobbs, O.B.Pedersen: Acta metall. 37, 3061 (1989).