Lecture-15

advertisement

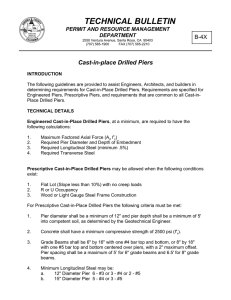

BOOKS: 1. 2. 3. 4. SOIL MECHANICS by T WILLIAM LAMBE & ROBERT V. WHITMAN, Wiley ASTERN FOUNDATION ANALYSIS & DESIGN by JOSEPH E. BOWLES, Mc Graw Hills GEOTECHNICAL ENGINEERING by SHASHI K GULHATI & MANOJ DATTA, TATA Mc Graw Hill SOIL MECHANICS AND FOUNDATION ENGINEERING by B C PUNMIA, A K JAIN & A K JAIN, Laxmi Publications Pvt. Ltd. Provide a solid massive foundation for heavy loads and high horizontal thrusts. Drilled piers are structural members of relatively large-diameter massive struts constructed and placed in a pre-excavated hole. They are referred to variously by civil engineers as bored piles, large-diameter piles, foundation piers, sub-piers, and drilled caissons. The shafts can be enlarged at the base, resulting in belled or under-reamed piers In areas where pile penetration is difficult, piers can be provided. Vibration and heave of soil are not caused as in installation of a driven pile. This is a decisive factor when the adjacent structure is on spread footings or short piles. Equipment used in the construction of drilled piers produces less noise and, hence, is quite suitable for areas near hospitals and similar institutions. There is a possibility of inspection and physical testing of the soil or rock conditions at the bottom of the pier. In the construction of piers, there is no displacement of volume of soil, and the problems of shifting and lifting are eliminated. Drilled piers generally require light construction equipment. They can resist high lateral stresses. A drilled pier derives its supporting power from both skin friction and bottom bearing as in a pile. Generally, the skin friction developing along the shaft is less compared to the end bearing capacity. The surface area of a drilled pier is less compared to the one available in a pile group. Thus, in many instances, the drilled piers are designed as a compression member subjected to a load on top and an equal reaction at the bottom, neglecting the skin friction. The ultimate load-bearing capacity of drilled piers can be computed as for piles as Qu = Qf + Qp For Cohesive soils: Qf = a cu As (Qp)n = 9 cu Ap a = 0.35 to 0.4 As = surface area cu = cohesion Ap = area of base In Non-Cohesive Soils (Qp)a = (g Db Bk) Ap (Qp)n = 𝐴𝑝 𝑞 ′ (𝑁𝑞 − 1) (Qp)ns = lower of (Qp)a OR (Qp)n /F Qf = (K s´v tand) (p Db L) (Qf)s = Qf /F Net Allowable Load on Pier: Qns= (Qp)ns + (Qf)s Type of soil Skin friction (kN/m2) Silt and soft clay Very stiff clay Loose sand Dense sand Dense gravel 7–29 48–192 12–34 34–67 48–96 are structural boxes or chambers that are sunk in place through the ground or water by systematically excavating below the bottom of the unit, which thereby descends to the final depth. These have a large cross-sectional area and hence provide high bearing capacity, which is much larger than what may be offered by a cluster of piles. are generally used for major foundation works because of the high construction cost. In general, a caisson foundation is recommended and found to be advantageous when (i) large-size boulders are encountered and (ii) a massive sub-structure is required to withstand large lateral stresses. Open Caissons These are concrete or masonry shafts which remain open both at the top and at the bottom during construction. The caisson is sunk into place, as the soil is removed from the inside, till the well sinks to the required depth. Then, a bottom concrete seal is made by depositing concrete. The well is pumped dry, after maturity of the bottom concrete seal, and filled with concrete or sand. Box Caissons These are structures with a closed bottom. They are constructed on land and transported and sunk in to the prepared foundations below the water level. Pneumatic Caissons These caissons have their top closed, and compressed air is used to stop the entry of water into the working chamber. Thus, excavation and concreting are done in a dry condition. The caisson is sunk as the excavation proceeds, and after reaching the required depth, the working chamber is filled with concrete.