Design of a mechanical testing device for ESEM for Bone fracture healing assessment

Design of a mechanical testing device for ESEM

for

Bone fracture healing assessment

Participants

• Project Sponsor

• Dr. Stephen Doty, Hospital of Special Surgery

• Project Advisors

• Luis Cardoso, Ph.D and Marom Bikson Ph.D from The

Biomedical Engineering Department at City College

• Stewart Russell, Ph.D

• Students

• Rasha Aaskar

• Gaurav Aggarwal

• Cristina Alexandrescu, Team Leader

• Francisco Saenz

Table of Contents

• Introduction

– Project Goals

– Clinical Need

– Physiology of Bone

Healing

• Background

– Current Testing Methods for Assessing Healing

• Concept Development

– Design Specifications

– Constraints

– Existing Products

• Concept Design

– Universal External Testing

Stage

– Concept 1: Piezo Actuator

– Concept 2: DC Electric Motor

– Advantages & Disadvantages

• Conclusion

Project Goals

• Develop a device that is capable to:

– Perform mechanical testing on fractured bone during the healing process

– Allow placement inside the ESEM for microscopic analysis

Clinical Need

• Understand the mechanisms of fracture healing

– Evaluation of the mechanical properties

– Microscopic assessment of the tissue composition

• Analyze the effects of different treatments in the fracture repair process

– Increase in rate of healing

– Improve the strength of the fracture site

• Improve patient’s quality of life

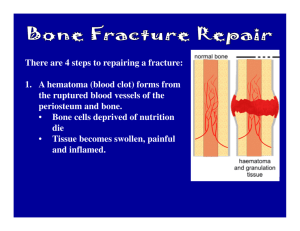

Physiology of Bone

Healing

• Inflammation

– Occurs immediately after fracture

– Mechanical stability is achieved by presence of hematoma

– Callus forms by bridging the fracture site

» Takes 2-3 days

• Reparation

– Callus size increases to unite fracture site and reduce bone motion

– Callus begins mineralization and eventually matures into lamellar bone --> bony union occurs

» Takes 4-12 weeks

•Remodeling

–Characterized by Wolff’s Law

–Fully restore anatomical configuration of bone

»Takes 6 months to 1 year in adults

Current Testing Methods for

Assessing Fracture Healing

• Qualitative methods

– Radiography

– Densitometry

• Quantitative methods

– Mechanical testing

• Three point bending

• Four point bending

• Torsion

These tests measure:

– Stiffness

– Ultimate load

– Work to failure

– Ultimate displacement

Hiltunen et al

Design Specifications

• Testing Method

– Four point bending inside the ESEM

• Components

– A motor that applies a chosen range of forces

– Sensors to measure:

• Displacement

• Force Applied

• Materials

– 440C Stainless Steel

– UHMWPE

– Rubber

– Copper Tubing

• Design should allow easy visualizations of bone callus for microscopic analysis

• The Data Acquisition will initially be done via Lab View and NI DAQ Hardware

Parameters

Workable Area

Length

Depth

Value

20 cm

8 cm

Height 10 cm

Internal Environmental Conditions

Type of Atmosphere

Temperature

Partial ~ 4000 Pa

25 Degrees Celsius

Measurement Feedback Scales

Force

Displacement

0 ~ 30 newtons

0 ~ 3 mm

Accuracy

Force 1 micro-newton

Displacement 0.01 mm

Force Lost Due to Components (Gears, shafts, couplers, etc.)

To The Bone 0.01 newtons

Constraints

• ESEM

– Minimal alterations to microscope

– Electromagnetic and environmental conditions

– Workable space inside the chamber

• Device Components

– Satisfy ESEM constraints

– Must be sturdy and secured inside the chamber

• Testing Conditions

– Bone hydration

Initial Concepts of

Internal Testing System

• Modification of existing stage gear system

– Requires excessive modification of the ESEM

• Use of the external port of the ESEM

– Requires the creation of a Vacuum seal

– Modification of the port assembly of the ESEM

These two concepts might result in damage of the ESEM and are too expensive to be pursued.

Existing Products

• There exist devices that meet the design criteria and overcome the imposed constraints

– Prices range from

$10,000-30,000

– Encompass all testing methods

– Customized software applications

Courtesy of www.gatan.com

Therefore…

• Existing commercial devices provide an immediate solution to the original design specifications

• However these systems are too expensive

• These challenges can be overcome by building an external device as opposed to an internal one. The external testing system will:

– Be a cheaper alternative to commercial devices

– Perform the most relevant testing method for fracture healing studies

– Specifically designed for testing of mouse bones

– Be portable for usage in multiple microscopes

– While having a self locking mechanism to maintain deformation

– Be used as a prototype for preliminary studies to determine clinical relevance

– Be safe for the ESEM

• No fragmentation of bone

• No alterations

• No EMF

Concept Designs

• Test system:

– Accommodates motors and linear actuators

– Minimizes alterations to the stage design.

• Criteria:

– Cost

– Accuracy

– Size

– Locking Mechanism

Universal External

Testing Stage

Interface for bone (consisting of hardened liquid polymer [polyethylene] and metal coupler). Applies four point bending force.

Z

Y

X

Load Cell

Physical stage constructed of Stainless Steel or polyethylene with maximum size of 20 x 8 x

10 cm

LVDT

Motor / Actuator

Concept 1

Piezo Actuator

• Composed of a ceramic material that expands and contracts in response to an applied electrical voltage

• Advantages

– Self locking when power is removed

– Rapid response

– High resolution

– Not subject to mechanical tear and wear

– Eliminates the need for an external LVDT

Piezo Actuator

(cont’d)

• Disadvantages

– Brittle

– Repeatability errors due to hysterisis and creep

– Higher costs of roughly $500

• An electrical motor converts electrical energy to mechanical energy using principles of magnetism to propel the armature

Concept 2

DC Electric Motor

http://en.wikipedia.org/wiki/Image:Electric_motor_cycle_1.png

• Advantages

DC Electric Motor

(cont’d)

– If operated only outside it would not create EMF inside the ESEM

– Very Inexpensive

• Costs can be less than

$100

• Disadvantages

– Constant power must be applied to maintain load

– Special locking clamps would be needed to maintain deformation

– Repeatability errors due to hysterisis and creep

– Requires external load and displacement sensor

– Requires design of gear system for linear displacement

External Testing System

• Advantages

– No EMF inside ESEM

– No possible damage to the ESEM

– No particle creation inside the ESEM from fracturing

– External testing system with the possibility to test inside, with appropriate shielding

– Cost effective in manufacturing

– Less need for shielding

• Disadvantages

– Power needs to be removed while imaging in the ESEM for no EMF generation

– Possibility of losing deformation during movement

Conclusion

• The risk of modification with an internal system, and the costs of existing devices has lead to the development of an external testing system

• Our design will provide an alternative solution to the sponsor’s original design specifications while still meeting the requirements of the device