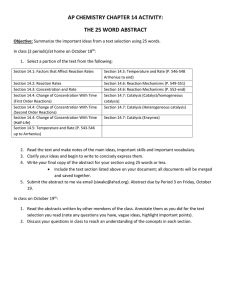

Al 3+ concentration dependence of Tb 3+ fluorescence in sol gel glasses

advertisement

3+ Al concentration dependence 3+ of Tb fluorescence in sol gel glasses Independent Study in Physics Jonathan Baker What I hope to communicate Who, what, when, where, why? Solution 1: Base Catalysis What is a Sol-Gel What we do with it Problems with sol-gel samples Why do it Results Solution 2: Acid Catalysis with Al3+ dopant Why do it Results…We found something NEW! we think What is a Sol-Gel? Alternative process for making glass Mix rare earth elements (Tb3+) into sample Examine local environment of host Examine energy dynamics of RE Why do we care about fluorescent yield? How the process works Densified Gel Densified It’s like cooking, only with toxic chemicals Key ingredient for me: the catalyst Gel Sodium Hydroxide Nitric Acid Base Catalysis Acid Catalysis Factors that hurt luminescent yield Presence of OH ions Phonon relaxation Also non-radiative Clustering Radiation-less energy migration among RE’s We think we can minimize these effects Base Catalysis (theory) Addresses OH problem Gel is dryer (less water) than acid catalysis Smaller pore size Acts less like a sponge Base Catalysis Acid Catalysis Base Catalysis (What I did) Adapted acid catalysis recipe Calculated amount of NaOH needed Trial and error finally led to success Still cooking Blank samples look hopeful Added Tb3+ into samples Success remains to be seen In the meantime… Return to Acid Catalysis Adding Al3+ to solution breaks up Terbium clusters Decreases cross relaxation That’s the idea…before I tell you if it worked, here’s what I did 5D 3 5D 4 7F 6 Ion 1 Ion 2 7F 0 Ion 1 Ion 2 Making Glass Heating Densifies dry gel to form a glass Organics (carbon) burned off Residual OH’s removed Pore size reduced Approaching melt glass quality Gel Densified Analyzing Glass 5D 4 0.015 Background Fluorescing levels 0.2% 0.02% I hope you like Excel 0.065 volts vs. time Subtracting the baseline 542nm and 437nm minus 450 nm 0.000 -0.035 0.001 0.001 0.002 437nm 0.002 0.003 0.003 0.004 0.004 437 437 - 450 -0.085 Analyzed two concentrations of Tb3+ 437nm data: 0.2%Tb:0.1%Al 5D 3 volts Excite 5D3 using Laser Detected at three wavelengths 450 -0.135 542nm -0.185 time (seconds) 542nm data: 0.2%Tb:0.8%Al 0.1 0 -0.005 -0.10.000 7F 6 7F 5 7F 4 7F 0 0.005 0.010 0.015 -0.2 volts -0.3 -0.4 -0.5 -0.6 -0.7 tim e (seconds) 0.020 0.025 Analyzing Data Three level diagram Two pathways to ground state Considered independently Modeled data using MathCAD Imported Excel files into MathCAD Fit data in MathCAD dY 0 R1Y 0 R 3Y 0 dt dY 1 R1Y 0 R 2Y 1 dt dY 2 R3Y 0 R 2Y 1 dt dY 0 dY 1 dY 2 0 dt dt dt More MathCAD Fits 0.2% Tb_data analysis_20to10 0.02% Tb_data analysis_10to1_reheated Back to Excel Plotted various rates and initial populations vs. concentration of aluminum R3 and R2: 5D3 to 7F6 and 5D4 to 7F6 R1: 5D3 to 5D4 45000 1600 40000 1400 35000 1200 1000 25000 rate rate 30000 20000 R3 R2 800 600 15000 10000 400 5000 200 0 0 0 0.5 1 1.5 3+ 3+ %Al :0.02%Tb 2 2.5 0 0.5 1 1.5 %Al3+:0.02%Tb3+ 2 2.5 Previous papers Montiel (1999) Tb3+ in silicate sol-gel glass doped with Al3+ Al3+ as cluster buster First proposed in 1994 Ishizaka (2001) Tb3+ in pure alumina sol-gel glass Gives R2 in pure alumina Montiel (2004) Just kidding! New Conclusions! (R2) R2: 5D4 to 7F6 600 500 rate 400 300 200 100 0 0 0.5 1 1.5 3+ %Al :0.02%Tb 2.5 Ishizaka results in pure alumina samples 2 3+ Our data: small percentage of aluminum (0% to 4%) Their smallest Tb concentration is too large to neglect cross relaxation contributions Ergo…a reasonable value for R2 for small (<0.1%) concentrations of Tb in pure alumina environment would be in the range from 200 to 300 s-1 This is the value we get for >0.25% Al in silicate glass Our data supports Montiel’s suggestion that Al is not a cluster buster Thank you Dr. Boye!