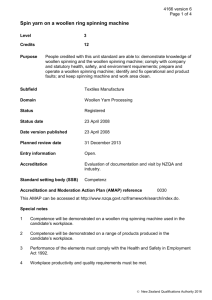

Demonstrate knowledge of woollen carding and spinning technology

4162 version 6

Page 1 of 5

Demonstrate knowledge of woollen carding and spinning technology

Level 5

Credits 20

Purpose People credited with this unit standard are able to demonstrate knowledge of: the nature and use of yarns manufactured on the woollen system; fibre and blend formulation for woollen spinning; woollen carding; card clothing used on a woollen card; woollen spinning; and tests used in woollen yarn manufacturing.

Subfield Textiles Manufacture

Domain

Status

Status date

Date version published

Woollen Yarn Processing

Registered

23 April 2008

23 April 2008

Planned review date

Entry information

31 December 2013

Open.

Accreditation Evaluation of documentation and visit by NZQA and industry.

Standard setting body (SSB) Competenz

Accreditation and Moderation Action Plan (AMAP) reference 0030

This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do.

Special notes

Information to support the learning required for this standard can be obtained from papers and articles published by AgResearch. These may be obtained by contacting AgResearch http://www.agresearch.co.nz and searching using the keyword Textiles.

New Zealand Qualifications Authority 2020

4162 version 6

Page 2 of 5

Elements and performance criteria

Element 1

Demonstrate knowledge of the nature and use of yarns manufactured on the woollen system.

Performance criteria

1.1 Woollen spun yarns are described in terms of their properties and end-use, and compared with semi-worsted and worsted yarns.

Range properties

– count range, evenness, strength, elongation, bulk, hairiness, twist; end-uses – woven apparel, knitted apparel, hand knitting yarn, carpets, furnishing, speciality products.

1.2 Fibres used for woollen processing are described in terms of fibre properties and suitability for end uses.

Range fibre types – wool and other natural fibres, man made fibres, wastes, noils, nops, neps, and blends from these groups; fibre properties

– fineness, length, strength, bulk, cost, handle, lustre, crimp, wool colour; end-uses

– woven apparel, knitted apparel, hand knitting yarn, carpets, furnishing.

Element 2

Demonstrate knowledge of fibre and blend formulation for woollen spinning.

Performance criteria

2.1 Properties of fibres and fibre blends are described in terms of processing performance and effects on yarn properties.

Range fibre properties – length, fineness, strength, bulk, colour, extension, stress and strain, crimp; fibre types – wool and other natural fibres, man made fibres, wastes, noils, nops, neps, and blends from these groups.

2.2 Processing additives that are applied in woollen processing are described in terms of their function and effect during processing and application quantities calculated.

Range processing lubricant, anti-stats, water, wetting agents, fugitive dyes.

New Zealand Qualifications Authority 2020

4162 version 6

Page 3 of 5

Element 3

Demonstrate knowledge of woollen carding.

Performance criteria

3.1 Woollen carding is described in terms of process objectives.

Range objectives – fibre mixing, fibre disentanglement, maintenance of fibre length, vegetable matter removal, web formation, condensing.

3.2 Woollen card sections and components are described in terms of function, setting and operation.

Range feed section including single hopper, double hopper, chute, scribbler, peralta, intermediate feed, carder, condenser.

3.3 Carding mechanisms used in woollen carding are described in terms of their function and operation.

Range feed mechanisms including mechanical or automatic, Servolap,

Microweigh, Microfeed; web monitoring systems; condenser mechanisms including rubbing and reciprocating action, series tape action, figure eight tape action, endless tape action; condenser creel mechanisms including high density spooling.

3.4 Carding actions are described and diagrams produced to illustrate the action.

Range point to point, point to back, back to back.

3.5 Card rollers are described in terms of their function, operation, setting, and location on the card.

Range feed, licker-in, swift, worker, stripper, fancy, peralta, doffer, tummer, condenser stripper, angle stripper, fly stripper, transfer roller, dickie roller.

3.6 Carded slubbing faults are described in terms of cause, significance, and corrective action.

Range neps, fibre breakage, short and long term count unevenness, cross card variation, double ends, strength, slubs, contamination.

New Zealand Qualifications Authority 2020

4162 version 6

Page 4 of 5

Element 4

Demonstrate knowledge of card clothing used on a woollen card.

Performance criteria

4.1 Card clothing used in woollen carding is described in terms of type, characteristics, and reasons for selection.

Range type – fillet, metallic; characteristics

– counts, crowns, gauge, wire angle, points, backs, foundation; reasons – card performance, yarn quality.

4.2 Fettling process is described in terms of reasons for fettling and methods used.

Range method – hand, vacuum, degreasing metallic wire; reasons

– carding performance, product quality, contamination.

4.3 Card clothing procedures are described in terms of techniques used to apply woollen card clothing.

Range fillet, metallic.

4.4

Element 5

Card grinding is described in terms of function and operation.

Demonstrate knowledge of woollen spinning.

Performance criteria

5.1 Woollen ring spinning machine sections and components are described in terms of function and operation.

Range creel, drafting zone, cots, false twist, lappets, spindle, spindle crown, balloon ring, ring, traveller, spindle brake, waste collection, waste recycling.

5.2 Spinning actions are described in terms of the mechanism and factors that affect the action.

Range draft, false twist, twist insertion, wind-on and package build.

5.3 Spinning faults are described in terms of cause, significance, and corrective action.

Range uneven yarn, unlevel twist, contamination, double ends, incorrect piecenings.

New Zealand Qualifications Authority 2020

4162 version 6

Page 5 of 5

Element 6

Demonstrate knowledge of tests used in woollen yarn manufacturing.

Performance criteria

6.1 Tests are described in terms of principles, method, and reason for each test.

Range regain, extractable matter, slubbing and yarn count, count variation, cross card variation, twist level, twist direction, twist variation, spindle speed variation, yarn strength and elongation, yarn shade, slub definition.

Please note

Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment.

Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards.

Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards.

Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The

AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements.

Comments on this unit standard

Please contact Competenz info@competenz.org.nz if you wish to suggest changes to the content of this unit standard.

New Zealand Qualifications Authority 2020