Demonstrate knowledge of woven fabrics

advertisement

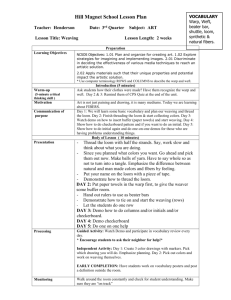

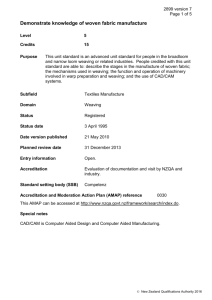

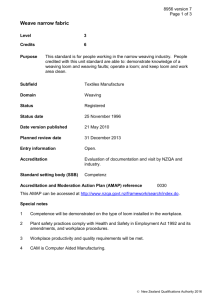

2897 version 7 Page 1 of 4 Demonstrate knowledge of woven fabrics Level 3 Credits 10 Purpose This unit standard is for people working in a textile manufacturing workplace. People credited with this unit standard are able to: explain fabric structure and weaving terms; describe warp and weft characteristics and preparation; explain the weaving process; and identify and describe basic weaves. Subfield Textiles Manufacture Domain Weaving Status Registered Status date 3 April 1995 Date version published 21 May 2010 Planned review date 31 December 2013 Entry information Open. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) Competenz Accreditation and Moderation Action Plan (AMAP) reference 0030 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes This unit standard recognises knowledge of woven fabrics, it builds on the knowledge covered by Unit 19841, Demonstrate elementary knowledge of the operations, processes and products of textile manufacturing. New Zealand Qualifications Authority 2016 2897 version 7 Page 2 of 4 Elements and performance criteria Element 1 Demonstrate knowledge of fabric structure and weaving terms. Range warp, weft, sett, weave. Performance criteria 1.1 Woven fabric structure is described and compared with other fabric construction methods. Range 1.2 woven, weft knitted, warp knitted, non-woven. Weaving terms are defined according to industry definitions. Range weft, warp, sett, balance, interlacing, weave. Element 2 Describe the characteristics and preparation of yarns used in the warp. Performance criteria 2.1 Warp yarn properties are described in terms of their effect on woven fabric structure and performance. Range 2.2 Warp preparation methods are described and compared in terms of their advantages and disadvantages. Range 2.3 yarn count, twist, fibre content, strength, abrasion resistance, evenness. direct, sectional. Sectional warp preparation and beaming procedures are described. Range creeling, pull through, take lease, run warp, set beam width, run beam, direct warp. 2.4 Warp break detectors are described in terms of their function and operation. 2.5 Chemicals applied to yarn during warp preparation are identified in terms of their type and use. Range type – size, antistat, wax; use – yarn abrasion, weaveability. New Zealand Qualifications Authority 2016 2897 version 7 Page 3 of 4 2.6 Drawing-in is described in terms of procedure used and loom components involved. Range headle wire, headle shaft, reed. Element 3 Explain weft insertion and describe the characteristics and preparation of yarns used in the weft. Performance criteria 3.1 Weft yarn properties are described in terms of their effect on woven fabric structure and performance. Range 3.2 Methods of weft insertion are described and compared in terms of the benefits and disadvantages of each method. Range 3.3 yarn count, twist, fibre content, strength, abrasion resistance, evenness, shrinkage. shuttle, projectile, rapier, water, air, rotary or ripple, binder. Selvedge formation is described in terms of the methods used. Range shuttle, tuck-in list, leno list, thermoseal, binder. Element 4 Demonstrate knowledge of the weaving process. Performance criteria 4.1 Parts of a simple loom are identified and described in terms of their function. Range 4.2 warp beam, headle shafts, headle wires, weft insertion mechanism, weft, reed, fell, shed, cloth beam, binder weft. Weaving cycle is described in terms of the steps in the cycle. Range let-off, shedding, weft insertion, beating-up, take-up. Element 5 Identify and describe the structure of different woven fabric types. Range plain, twill, satin. Performance criteria 5.1 Fabrics are identified by type and weave. New Zealand Qualifications Authority 2016 2897 version 7 Page 4 of 4 5.2 Weaves are described in terms of interlacing and point paper notation. 5.3 Fabrics are described in terms of appearance, fabric properties and end-use. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact Competenz info@competenz.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016