Operate and monitor boilers and auxiliary plant on a seafood

advertisement

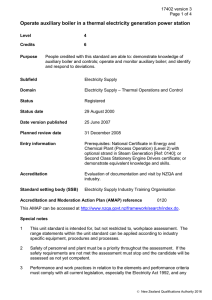

23026 version 2 Page 1 of 4 Operate and monitor boilers and auxiliary plant on a seafood processing vessel Level 3 Credits 6 Purpose People credited with this unit standard are able to: demonstrate knowledge of, operate, and monitor seafood processing vessel boiler and auxiliary plant. Subfield Seafood Domain Seafood Vessel Operations Status Registered Status date 11 December 2009 Date version published 11 December 2009 Planned review date 31 December 2014 Entry information Open. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) Primary Industry Training Organisation Accreditation and Moderation Action Plan (AMAP) reference 0123 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Definitions Company requirements refer to instructions to staff on policy and procedures that are communicated in an oral or written form. These requirements must include legislation and safety requirements and manufacturer’s requirements, and may include but are not limited to, industry codes of practice and standards. Code refers to the Approved Code of Practice for the Design, Safe Operation, Maintenance and Servicing of Boilers, 2005, published by the Occupational Safety and Health Service of the Department of Labour, available at http://www.osh.dol.govt.nz. New Zealand Qualifications Authority 2016 23026 version 2 Page 2 of 4 2 Legislation relevant to this unit standard includes but is not limited to – the Hazardous Substances and New Organisms Act 1996, the Health and Safety in Employment Act 1992, the Maritime Transport Act 1994, the Maritime Rules and Marine Protection Rules and advisory circulars issued under the Act. Elements and performance criteria Element 1 Demonstrate knowledge of seafood processing vessel boiler and auxiliary plant. Performance criteria 1.1 The relevant sections of the code are described in relation to the requirements for 1.2 megawatt to 6 megawatt boilers. Range controls and mountings, trip systems, alarms, supervision, monitoring. 1.2 The steps required for boiler pre start-up and start-up are described in terms of their purpose in terms of company requirements. 1.3 Inputs to the boiler alarms and trips are identified and their purpose and settings are described in terms of safe boiler operation. 1.4 Equipment installed on the boiler is identified and described in terms of its operating principles and purpose. Range 1.5 instrumentation, gauge glasses, safety devices, fuel system, burners, fans, valves, dosing system, feed water system, safety valves, blowdown system. Emergency shut-down devices are located and identified, and the procedure for making the boiler system safe in the event of an emergency is explained and simulated in accordance with company requirements. Range emergencies include but are not limited to – fire, hazardous spill, steam leaks, water loss. 1.6 The boiler visual display panel is identified, and presented date is described in terms of the boiler and auxiliary equipment operating status. 1.7 Site-specific chemicals used in the boiler feed water system are identified, and their purpose and the safety precautions required for their use are described in accordance with company requirements. New Zealand Qualifications Authority 2016 23026 version 2 Page 3 of 4 Element 2 Operate seafood processing vessel boiler and auxiliary plant. Performance criteria 2.1 Pre start-up checks are described in terms of their purpose and are carried out in accordance with company requirements. 2.2 The boiler is started up and shut down in accordance with company requirements. 2.3 The boiler is brought on line in accordance with company requirements. 2.4 Routine procedures are carried out in accordance with company requirements. Range plant logs, plant monitoring, maintaining performance specifications, planned preventative maintenance and cleaning, blowdown operation, boiler water testing. 2.5 Boiler gauge glasses are identified, and the gauge glass blowdown procedure is carried out in accordance with company requirements. 2.6 Boiler gauge glass problems are identified and solutions to these problems are described in accordance with company requirements. Range scale, corrosion, foaming, carry-over. 2.7 Post shut-down checks are carried out in accordance with company requirements. 2.8 Boiler isolation for maintenance is carried out or simulated in accordance with company requirements. 2.9 Feed water chemicals are handled safely and dosed in accordance with company requirements. Element 3 Monitor seafood processing vessel boiler and auxiliary plant. Performance criteria 3.1 Boiler and auxiliary equipment are monitored and information is logged and interpreted in accordance with company requirements. 3.2 Deviations from normal operating conditions are identified, causes of the deviations are described, and steps to rectify them are taken in accordance with company requirements. New Zealand Qualifications Authority 2016 23026 version 2 Page 4 of 4 3.3 Boiler water samples are taken, analysed and logged, deviations from required operating parameters are identified, and the steps to correct them are taken in accordance with company requirements. 3.4 The consequences of incorrect water treatment are described in terms of their effect on equipment and heat transfer efficiency. Range scale, corrosion, foaming, carry-over. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Primary Industry Training Organisation at standards@primaryito.ac.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016