NZQA unit standard 13347 version 5

advertisement

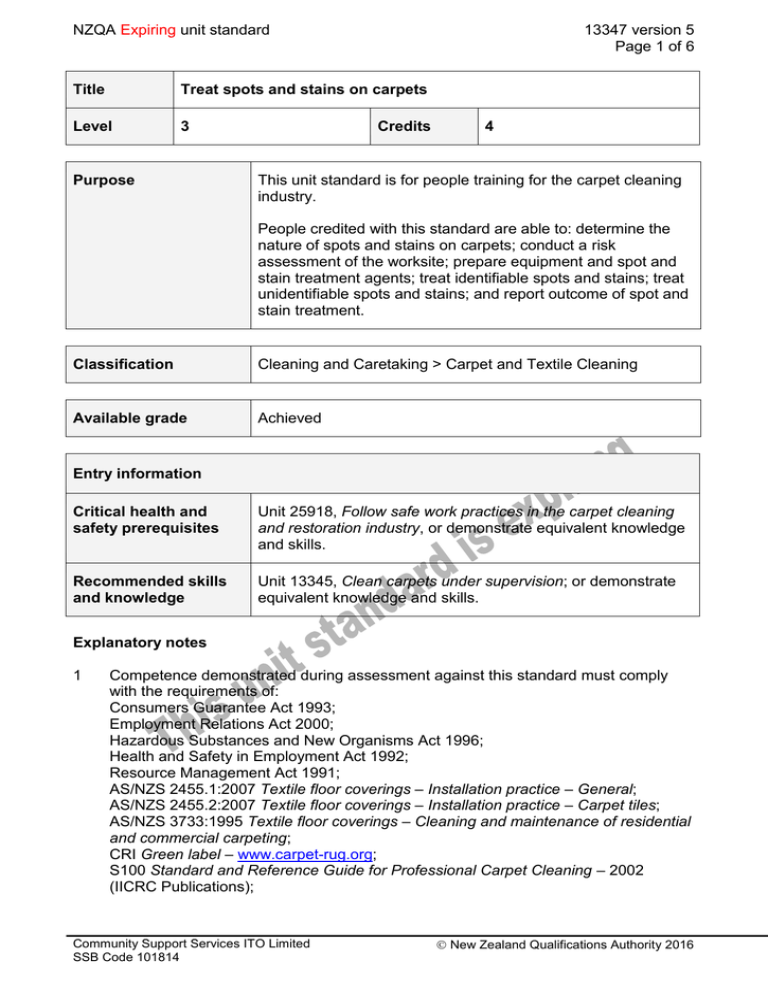

NZQA Expiring unit standard 13347 version 5 Page 1 of 6 Title Treat spots and stains on carpets Level 3 Purpose Credits 4 This unit standard is for people training for the carpet cleaning industry. People credited with this standard are able to: determine the nature of spots and stains on carpets; conduct a risk assessment of the worksite; prepare equipment and spot and stain treatment agents; treat identifiable spots and stains; treat unidentifiable spots and stains; and report outcome of spot and stain treatment. Classification Cleaning and Caretaking > Carpet and Textile Cleaning Available grade Achieved Entry information Critical health and safety prerequisites Unit 25918, Follow safe work practices in the carpet cleaning and restoration industry, or demonstrate equivalent knowledge and skills. Recommended skills and knowledge Unit 13345, Clean carpets under supervision; or demonstrate equivalent knowledge and skills. Explanatory notes 1 Competence demonstrated during assessment against this standard must comply with the requirements of: Consumers Guarantee Act 1993; Employment Relations Act 2000; Hazardous Substances and New Organisms Act 1996; Health and Safety in Employment Act 1992; Resource Management Act 1991; AS/NZS 2455.1:2007 Textile floor coverings – Installation practice – General; AS/NZS 2455.2:2007 Textile floor coverings – Installation practice – Carpet tiles; AS/NZS 3733:1995 Textile floor coverings – Cleaning and maintenance of residential and commercial carpeting; CRI Green label – www.carpet-rug.org; S100 Standard and Reference Guide for Professional Carpet Cleaning – 2002 (IICRC Publications); Community Support Services ITO Limited SSB Code 101814 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 13347 version 5 Page 2 of 6 ANSI/IICRC S520 Standard and Reference Guide for Professional Mould Remediation – 2008 (IICRC Publications). 2 Definitions Industry best practice refers to enterprise and/or establishment requirements and practices which are in accordance with applicable legislation, regulations and safety data sheets. Organisational requirements refers to instructions to staff on policy procedures and methods relating to cleaning in the workplace (including health and safety) and the application of any written procedures which are documented in memo or manual format and are available in the workplace. A spot is defined as a concentrated substance which sits on the surface of the fabric or material and changes the texture or appearance of that fabric or material. A stain is defined as foreign material (soil, liquid, etc) on a fabric or material that is not removable by standard cleaning methods. This also includes discolouration occurring in or on a fabric or material or any colour other that the natural colour of the fabric or material (ie. red stain, black stain). Spotting is defined as the application of chemical cleaning agents with a colour-fast cloth, using a dabbing motion, from the outside edge towards the centre, in order to remove spots and stains. Sequence of best practice is determined by the procedure for the removal of spots and stains. Outcomes and evidence requirements Outcome 1 Determine the nature of spots and stains on carpets. Range composition and appearance of spotted and stained material, cause of spot and stain. Evidence requirements 1.1 Spotted and stained carpet fibres are identified by using industry standard fibre identification method. Range wool, nylon, olefin/polypropylene. 1.2 Identification of fibre composition ensures that appropriate spot and stain treatment agents are selected in accordance with industry best practice. 1.3 Assessment of spot and stain determines substance causing spots and stains. Range 1.4 one of – positive identification by client, through reference to AS/NZS 3733:1995, appendix A. For unidentified stains – location, feel, appearance, odour, colour, pH, age. Results of assessment and recommendations for treating spots and stains are documented and reported to the client in accordance with industry best practice. Community Support Services ITO Limited SSB Code 101814 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 13347 version 5 Page 3 of 6 Outcome 2 Conduct a risk assessment of the worksite. Evidence requirements 2.1 A risk assessment of the worksite is completed in accordance with industry best practice. Range immediate and secondary risks. 2.2 Client is provided with written details of the risk assessment in accordance with industry best practice. 2.3 Client’s written acceptance of the risk assessment is obtained prior to carpet cleaning in accordance with industry best practice. Outcome 3 Prepare equipment and spot and stain treatment agents. Evidence requirements 3.1 Equipment is selected for the identified fibre type, spot and stain in accordance with industry best practice. Range 3.2 may include – spotting kit, pH paper, tamping brush, bone scraper, spatula, duck bill scissors, absorbent towelling, hot water extraction machine. Evidence of six is required. Spot and stain treatment agents are selected according to the fibre type and the particular spot or stain. Range may include – volatile dry solvent, non-volatile dry solvent, acid spotter, alkaline spotter, oxidising agent, reducing agent, enzyme digester, rust remover. Evidence of five is required. 3.3 Personal protective equipment and equipment are used in accordance with manufacturer’s recommendations and industry best practice. 3.4 Spot and stain treatment agents are prepared according to manufacturer's recommendations. Community Support Services ITO Limited SSB Code 101814 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 13347 version 5 Page 4 of 6 Outcome 4 Treat identifiable spots and stains. Evidence requirements 4.1 Warning signs are displayed in accordance with industry best practice and organisational requirements. Range 4.2 Risk of damage to carpet is minimised by the application of prepared spot and stain treatment solution to an inconspicuous area. Range 4.3 at least one of – signs, cordons, barriers. colour bleeding/fastness, change in pile texture. Conditions for safe spot and stain removal are met. Range adequate ventilation, absence of naked flames, avoidance of inhalation and contact with skin and eyes. 4.4 Spot and stain treatment solution is applied to spots and stains of identifiable origin according to manufacturer's recommendations. 4.5 Soiled solutions and waste are disposed of in accordance with the Resource Management Act 1991. Outcome 5 Treat unidentifiable spots and stains. Evidence requirements 5.1 Warning signs are displayed in accordance with industry best practice and organisational requirements. Range 5.2 Risk of damage to carpet is minimised by the application of prepared spot and stain treatment solution to an inconspicuous area. Range 5.3 colour bleeding/fastness, change in pile texture. Conditions for safe spot and stain removal are met. Range 5.4 at least one of – signs, cordons, barriers. adequate ventilation, absence of naked flames, avoidance of inhalation and contact with skin and eyes. Spots and stains of uncertain or unknown origin are treated in the sequence of best practice until there is evidence of soil or colour transfer. Community Support Services ITO Limited SSB Code 101814 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 5.5 13347 version 5 Page 5 of 6 Soiled solutions and waste are disposed of in accordance with the Resource Management Act 1991. Outcome 6 Report outcome of spot and stain treatment. Evidence requirements 6.1 The outcome of treating spots and stains is documented and reported to the client in accordance with industry best practice. Range 6.2 source of spots and stains, unsuccessfully treated spots and stains, spot and stain prevention, first aid treatment for carpets when spots and stains occur, explanation about reoccurrence of some stains and spots. Premises are secured in accordance with client requirements and/or instructions. Replacement information This unit standard, unit standard 1570, unit standard 1572 and unit standard 1576 were replaced by unit standards 29383 and 29386. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 20 December 1998 31 December 2014 Review 2 27 April 2004 31 December 2014 Review 3 16 October 2009 31 December 2014 Review 4 18 October 2012 31 December 2018 Review 5 21 April 2016 31 December 2018 Consent and Moderation Requirements (CMR) reference 0004 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Community Support Services ITO Limited SSB Code 101814 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 13347 version 5 Page 6 of 6 Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMRs). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Community Support Services ITO Limited SSB Code 101814 New Zealand Qualifications Authority 2016