NZQA unit standard 15143 version 3

advertisement

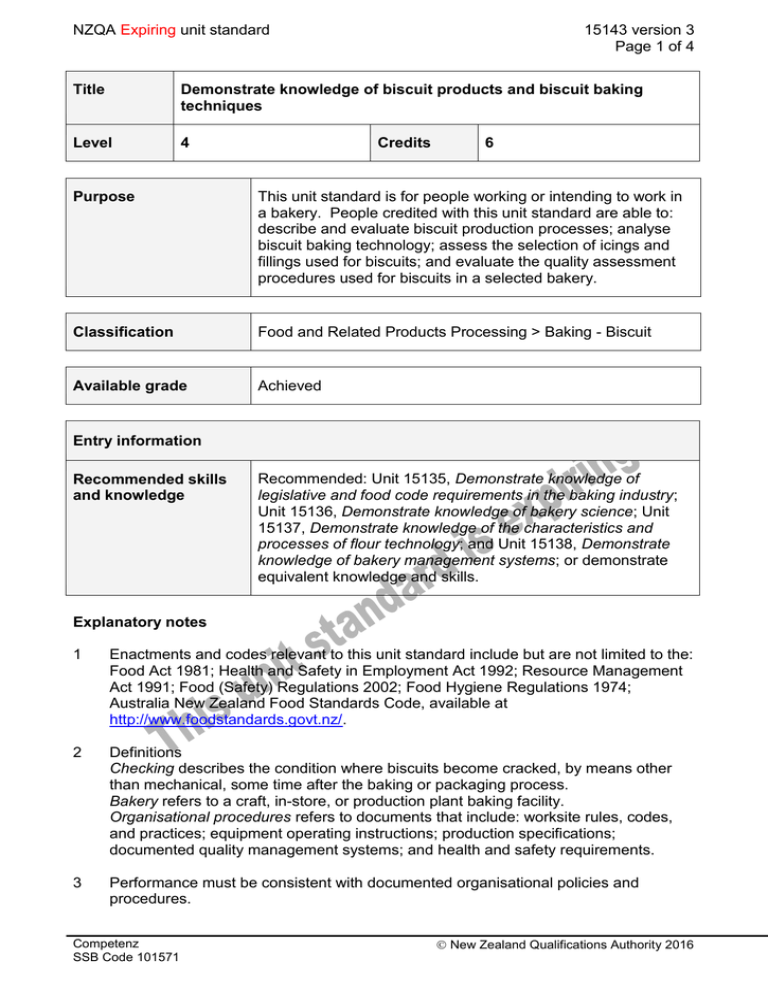

NZQA Expiring unit standard 15143 version 3 Page 1 of 4 Title Demonstrate knowledge of biscuit products and biscuit baking techniques Level 4 Credits 6 Purpose This unit standard is for people working or intending to work in a bakery. People credited with this unit standard are able to: describe and evaluate biscuit production processes; analyse biscuit baking technology; assess the selection of icings and fillings used for biscuits; and evaluate the quality assessment procedures used for biscuits in a selected bakery. Classification Food and Related Products Processing > Baking - Biscuit Available grade Achieved Entry information Recommended skills and knowledge Recommended: Unit 15135, Demonstrate knowledge of legislative and food code requirements in the baking industry; Unit 15136, Demonstrate knowledge of bakery science; Unit 15137, Demonstrate knowledge of the characteristics and processes of flour technology; and Unit 15138, Demonstrate knowledge of bakery management systems; or demonstrate equivalent knowledge and skills. Explanatory notes 1 Enactments and codes relevant to this unit standard include but are not limited to the: Food Act 1981; Health and Safety in Employment Act 1992; Resource Management Act 1991; Food (Safety) Regulations 2002; Food Hygiene Regulations 1974; Australia New Zealand Food Standards Code, available at http://www.foodstandards.govt.nz/. 2 Definitions Checking describes the condition where biscuits become cracked, by means other than mechanical, some time after the baking or packaging process. Bakery refers to a craft, in-store, or production plant baking facility. Organisational procedures refers to documents that include: worksite rules, codes, and practices; equipment operating instructions; production specifications; documented quality management systems; and health and safety requirements. 3 Performance must be consistent with documented organisational policies and procedures. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 15143 version 3 Page 2 of 4 Outcomes and evidence requirements Outcome 1 Describe and evaluate biscuit production processes. Evidence requirements 1.1 Biscuit types are classified according to processing methods. Range deposited, rotary moulded, rotary cut, wire cut, extruded, reciprocating cutter, hand cut. 1.2 Biscuit ingredients are evaluated in terms of form, function, and use. 1.3 Biscuit making process is outlined and explained in terms of sequential steps. Range 1.4 preparation and weighing of ingredients, mixing, shaping, baking, cooling, finishing, packaging. Methods for minimising and re-using dough trim are assessed against recommended dough specifications. Outcome 2 Analyse biscuit baking technology. Evidence requirements 2.1 Baking temperatures for selected biscuit types are determined from an analysis of recipes and current bakery practice. Range 2.2 Baking times for selected biscuit types are determined from an analysis of recipes and current bakery practice. Range 2.3 deposited, rotary moulded, rotary cut, wire cut, extruded, reciprocating cutter, hand cut. deposited, rotary moulded, rotary cut, wire cut, extruded, reciprocating cutter, hand cut. The baking process is analysed in terms of the physical and chemical changes that occur in biscuit doughs. Outcome 3 Assess the selection of icings and fillings used for biscuits. Evidence requirements 3.1 Commonly used icings are classified in terms of recipe balance, characteristics, and use. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard Range 3.2 flat icings, fondant, creamed icings, almond paste, glazes, marshmallow, chocolate. Commonly used fillings are classified in terms of recipe balance, characteristics, and use. Range 3.3 15143 version 3 Page 3 of 4 ganache, custard, caramel, jam, creamed icings. Methods for filling and icing biscuits are compared against specifications for finished product and application techniques. Outcome 4 Evaluate the quality assessment procedures used for biscuits in a selected bakery. Evidence requirements 4.1 Factors which determine the quality of biscuits are identified from quality assessment sheets. Range colour, size, uniformity, texture, presence of checking, flavour, mouthfeel, blooming on chocolate biscuits. 4.2 Causes of poor biscuit quality are established and corrective measures outlined from an analysis of ingredient quality, recipe balance, and processing methods. 4.3 Quality assessment procedures used in a selected bakery are evaluated against the specific product characteristics, scales of production, intended sell-by date, customer base, and use of information. Range frequency and number of samples assessed, assessment method, recording and reporting of results. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 27 November 1998 31 December 2018 Review 2 20 April 2006 31 December 2018 Review 3 17 March 2016 31 December 2018 Consent and Moderation Requirements (CMR) reference 0111 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 15143 version 3 Page 4 of 4 Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016