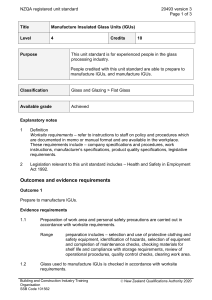

NZQA unit standard 20522 version 4

advertisement

NZQA Expiring unit standard Title Edgework glass manually Level 3 20522 version 4 Page 1 of 3 Credits Purpose 2 This unit standard is for people in the glass processing industry. People credited with this unit standard are able to prepare to edgework glass manually and edgework glass manually. Classification Glass and Glazing > Flat Glass Available grade Achieved Explanatory notes 1 Definition Worksite requirements – refer to instructions to staff on policy and procedures which are documented in memo or manual format and are available in the workplace. These requirements include but are not limited to – company specifications and procedures, work instructions, manufacturer’s specifications, product quality specifications, legislative requirements. 2 All work to be done in accordance with the requirements of the Health and Safety in Employment Act 1992 and Resource Management Act 1991. 3 For the purposes of assessment of this unit standard at least two of following items of equipment are to be demonstrated – portable belt sander, upright single belt linisher, upright cross belt linisher, upright diamond pencil edge machine. Outcomes and evidence requirements Outcome 1 Prepare to edgework glass manually. Evidence requirements 1.1 Preparation of work area and personal safety precautions are carried out in accordance with worksite requirements. Range preparation may include but is not limited to – selection and use of protective clothing and safety equipment, identification of hazards; may include but is not limited to – ventilation of production area, clearing work area, ensuring cleanliness of work area. Building and Construction Industry Training Organisation SSB Code 101562 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 20522 version 4 Page 2 of 3 1.2 Edgeworking area is checked to ensure it is clear of debris and abrasive material before work commences in accordance with worksite requirements. 1.3 Tools and equipment selected enable the work to be completed without damage to the glass, tools and equipment or injury to personnel in accordance with worksite requirements. 1.4 Tools and equipment are prepared for edgeworking in accordance with worksite requirements. Range 1.5 preparation may include but is not limited to – checking and dressing tools, checking coolant and water tanks, checking machine, wheel and belt wear, checking coolant and lubricant flow. Glass to be processed is checked to make sure it meets job specifications and worksite requirements. Range includes but is not limited to – correct size, thickness, weight and type, free from faults, edge damage, surface damage. Outcome 2 Edgework glass manually. Evidence requirements 2.1 Tools and equipment are used to complete edgeworking tasks to specification and in accordance with worksite requirements. Range 2.2 Glass is cleaned after edgeworking in accordance with worksite requirements. Range 2.3 edgeworking tasks include but are not limited to – rough arris, smooth arris, flat grind. may include but is not limited to – hand wash and dry, machine wash and dry. Finished glass is checked to ensure it meets job specifications and worksite requirements. Range may include but is not limited to – freedom from faults, surface or edge damage. 2.4 Finished glass is labelled or marked and prepared for dispatch or further processing in accordance with worksite requirements. 2.5 Work area and equipment are left clean and free from edgeworking debris in accordance with worksite requirements. Building and Construction Industry Training Organisation SSB Code 101562 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard Replacement information 20522 version 4 Page 3 of 3 This unit standard, unit standard 20513, and unit standard 26032 were replaced by unit standard 28756. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 27 April 2004 31 December 2017 Review 2 21 May 2010 31 December 2017 Review 3 18 June 2015 31 December 2017 Rollover 4 15 October 2015 31 December 2020 Consent and Moderation Requirements (CMR) reference 0073 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Building and Construction Industry Training Organisation SSB Code 101562 New Zealand Qualifications Authority 2016