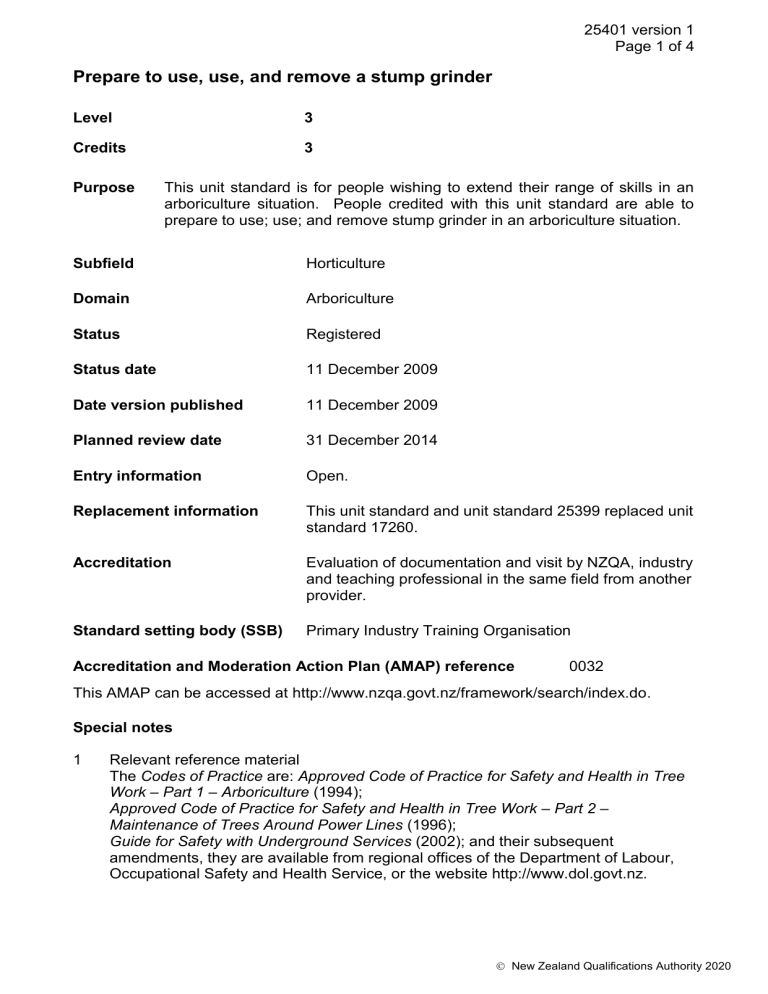

Prepare to use, use, and remove a stump grinder

25401 version 1

Page 1 of 4

Prepare to use, use, and remove a stump grinder

Level 3

Credits 3

Purpose This unit standard is for people wishing to extend their range of skills in an arboriculture situation. People credited with this unit standard are able to prepare to use; use; and remove stump grinder in an arboriculture situation.

Subfield Horticulture

Domain

Status

Status date

Date version published

Arboriculture

Registered

11 December 2009

11 December 2009

Planned review date

Entry information

31 December 2014

Open.

Replacement information

Accreditation

This unit standard and unit standard 25399 replaced unit standard 17260.

Evaluation of documentation and visit by NZQA, industry and teaching professional in the same field from another provider.

Standard setting body (SSB) Primary Industry Training Organisation

Accreditation and Moderation Action Plan (AMAP) reference 0032

This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do.

Special notes

1 Relevant reference material

The Codes of Practice are: Approved Code of Practice for Safety and Health in Tree

Work – Part 1 – Arboriculture (1994);

Approved Code of Practice for Safety and Health in Tree Work

– Part 2 –

Maintenance of Trees Around Power Lines (1996);

Guide for Safety with Underground Services (2002); and their subsequent amendments, they are available from regional offices of the Department of Labour,

Occupational Safety and Health Service, or the website http://www.dol.govt.nz.

New Zealand Qualifications Authority 2020

25401 version 1

Page 2 of 4

Working on the Road: A Handbook for Temporary Traffic Control and Safety at

Roadworks Sites , available from the NZ Transport Agency (NZTA).

The Standards are: BS 3998:1989 Recommendations for tree work ; available from http://www.standardsuk.com; ANSI Z133.1-2006 Safety Requirements ; ANSI A300

Standards for Tree Care Operations (Parts 1 – 7) and their subsequent amendments, available from the website: http://www.isa-arbor.com.

2 Legislation relevant to this unit standard includes

– Health and Safety in Employment

Act 1992, Health and Safety in Employment Regulations 1995; and their subsequent amendments.

3 Definition

Workplace procedures refer to oral or written instructions to staff on procedures for the worksite and equipment.

Elements and performance criteria

Element 1

Prepare to use a stump grinder in an arboriculture situation.

Performance criteria

1.1 Personal safety equipment is verified as fit for purpose and used in accordance with workplace procedures and manufacturer’s instructions.

Range includes but is not limited to

– safety footwear, gloves, non-catch clothes, hard hat, hearing and eye protection.

1.2 Stump grinder is checked and serviced in accordance with workplace procedures and manufacturer’s instructions.

Range includes but is not limited to

– inspecting of all safety features; checking trailer for road-worthiness, security of stump grinder on trailer; checking for anything loose; fuel, coolant and, hydraulic oil levels.

1.3 Arboriculture site is checked for underground services in accordance with the

Codes of Practice.

1.4 The stump grinder is prepared in accordance with workplace procedures and manufacturer’s instructions.

Range includes but is not limited to

– pre-start checks; greasing all relevant grease points; checking condition of stump grinder teeth; erecting barriers/signage where necessary.

New Zealand Qualifications Authority 2020

25401 version 1

Page 3 of 4

Element 2

Use a stump grinder.

Performance criteria

2.1 Stump grinder is positioned for use in accordance with workplace procedures and manufacturer’s instructions.

Range includes but is not limited to – starting stump grinder and moving to stump, choosing work direction; positioning stump grinder ready to grind over stump.

2.2 Stump grinder is operated in accordance with workplace procedures and manufacturer’s instructions.

Range includes but is not limited to – starting stump grinder and bringing it up to operating speed, understanding safe stopping procedures, ensuring stump is ground below ground level, maintaining stump grinder wheel speed, using reverse as needed, stopping stump grinder and immobilising motor if left unattended.

Element 3

Remove stump grinder from site.

Performance criteria

3.1 Stump grinder is transported off site at the end of the day in accordance with workplace procedures.

Range to include but is not limited to – putting the stump grinder into the transport format, removing it from the site in a safe and secure manner, noting and actioning any faults in the brushwood chipper.

3.2 Work is completed and site is left in a condition that is in accordance with any contract specifications and the workplace procedures.

Please note

Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment.

Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards.

Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards.

New Zealand Qualifications Authority 2020

25401 version 1

Page 4 of 4

Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The

AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements.

Comments on this unit standard

Please contact the Primary Industry Training Organisation http://www.primaryito.ac.nz

if you wish to suggest changes to the content of this unit standard.

New Zealand Qualifications Authority 2020