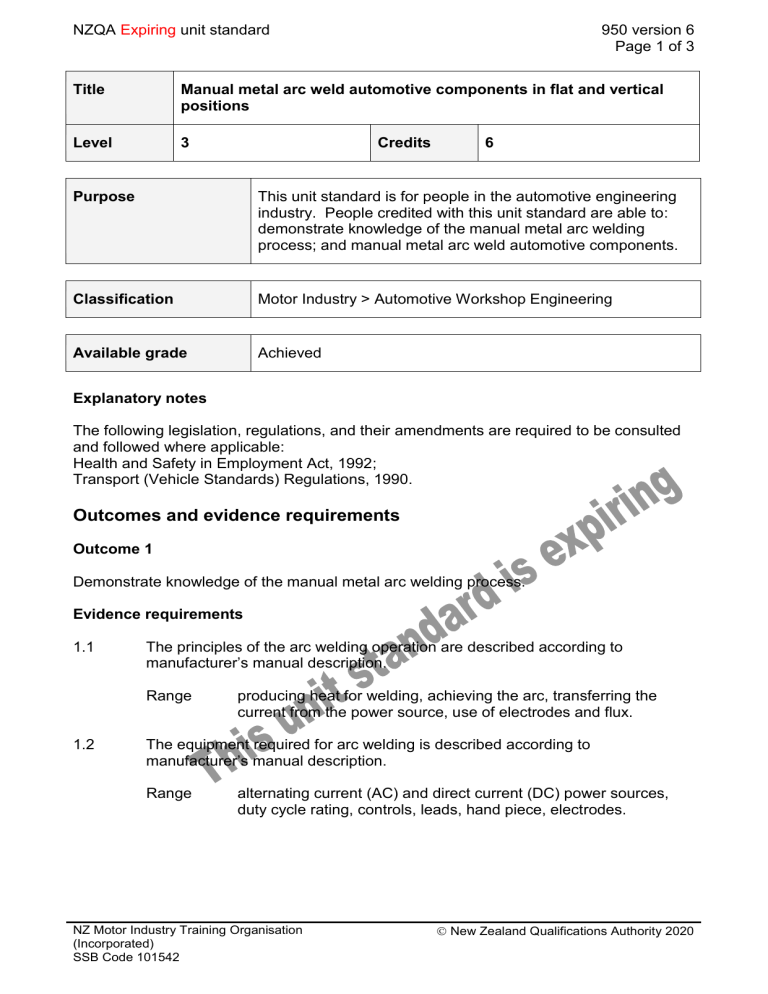

NZQA unit standard 950 version 6

NZQA Expiring unit standard

Title

950 version 6

Page 1 of 3

Manual metal arc weld automotive components in flat and vertical positions

Level

Purpose

3 Credits 6

This unit standard is for people in the automotive engineering industry. People credited with this unit standard are able to: demonstrate knowledge of the manual metal arc welding process; and manual metal arc weld automotive components.

Classification Motor Industry > Automotive Workshop Engineering

Available grade Achieved

Explanatory notes

The following legislation, regulations, and their amendments are required to be consulted and followed where applicable:

Health and Safety in Employment Act, 1992;

Transport (Vehicle Standards) Regulations, 1990.

Outcomes and evidence requirements

Outcome 1

Demonstrate knowledge of the manual metal arc welding process.

Evidence requirements

1.1 The principles of the arc welding operation are described according to manufacturer’s manual description.

Range producing heat for welding, achieving the arc, transferring the current from the power source, use of electrodes and flux.

1.2 The equipment required for arc welding is described according to manufacturer’s manual description.

Range alternating current (AC) and direct current (DC) power sources, duty cycle rating, controls, leads, hand piece, electrodes.

New Zealand Qualifications Authority 2020 NZ Motor Industry Training Organisation

(Incorporated)

SSB Code 101542

NZQA Expiring unit standard

1.3

950 version 6

Page 2 of 3

The essentials of arc welding are described according to manufacturer’s manual description.

Range arc length, choice of electrode, current range, angle of the electrode, speed of travel.

1.4 The handling and storage of electrodes are described according to manufacturer’s packet description.

Range effects of dampness, loss of flux coating.

1.5 The arc welding procedure is described according to manufacturer’s manual description.

Range weld preparation, welding positions, striking the arc, running a bead, cleaning.

1.6 Welding faults and their causes are identified.

Range porosity, cracking, slag inclusion, undercut, residual stress and distortion, weld appearance due to incorrect current and incorrect speed.

1.7 Procedures to protect a veh icle and/or machine’s electronic systems are described according to vehicle and/or machine manufacturer’s workshop manual instructions.

1.8 Procedures to provide heat shielding of adjacent components are identified.

Outcome 2

Manual metal arc weld automotive components.

Evidence requirements

2.1 Safety precautions are followed throughout the electric arc welding operation.

Range safety of the operator, the equipment, nearby personnel.

2.2 No damage occurs to the vehicle's or result of the welding. machine's electronic systems as a direct

2.3 The components are prepared to ensure a sound basis for welding.

Range removal of contaminants from the surface to be welded, joint preparation, component positioned.

2.4 Heat shielding of adjacent vehicle or machine components is carried out to prevent any damage or risk of fire or explosion.

New Zealand Qualifications Authority 2020 NZ Motor Industry Training Organisation

(Incorporated)

SSB Code 101542

NZQA Expiring unit standard

2.5 The components are welded in flat and vertical positions.

Range

950 version 6

Page 3 of 3 safety precautions taken, setting up the plant, adjustment of equipment, selection of electrode for the job, full penetration, appearance of weld run and finished job.

2.6 The welding equipment is stored in a safe and tidy manner after use.

Replacement information This unit standard has been replaced by unit standard

24372 and unit standard 24373.

This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below.

Status information and last date for assessment for superseded versions

Process Version Date Last Date for Assessment

Registration 1 9 November 1993 31 December 2016

Review

Review

Review

Rollover

2

3

4

5

4 October 1996

26 February 1999

20 March 2008

19 November 2010

31 December 2016

31 December 2016

31 December 2020

31 December 2020

Rollover 6 22 August 2014 31 December 2020

Consent and Moderation Requirements (CMR) reference 0014

This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do

.

Please note

Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment.

Industry Training Organisations must be granted consent to assess against standards by

NZQA before they can register credits from assessment against unit standards.

Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards.

Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The

CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements.

New Zealand Qualifications Authority 2020 NZ Motor Industry Training Organisation

(Incorporated)

SSB Code 101542