Confined Space Program Template

advertisement

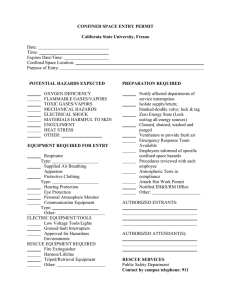

DEPARTMENT NAME:________________ PERMIT-REQUIRED CONFINED SPACE ENTRY PROGRAM DATE IMPLEMENTED: DATE REVISED: STATEMENT OF POLICY All permit-required confined spaces will be identified, evaluated, classified, and labeled. Written entry procedures and an entry permit system will be developed and implemented for all work performed in these spaces. All employees involved with this type of work will be properly trained and equipped. RELATED Enter related regulations here:________________________ SCOPE AND APPLICATION This program applies to all permit-required confined spaces, but various sections of this program may or may not apply based on whether or not entry into these spaces is permitted, and if so, by whom (employees, contractors, etc.). Per OSHA interpretations (see OSHA letter of interpretation, February 8, 2005 to Mr. Ronald Demaray), this program does not apply to entry into grain storage structures including grain bins and silos. See the Grain Handling Safety program for information and requirements for entering and working in grain storage structures. DEFINITIONS "Confined space" means a space that (a) Is large enough and so configured that an employee can bodily enter and perform assigned work; and (b) Has limited or restricted means for entry or exit (for example, tanks, vessels, storage bins, hoppers, vaults, and pits are spaces that may have limited means of entry.); and (c) Is not designed for continuous employee occupancy. NOTE: Neither this program, nor the OSHA regulation apply to entries made into confined spaces unless that space also meets the definition of “PermitRequired Confined Space”, which is defined below. "Permit-required confined space (permit space)" means a space which meets the definition of “confined space” (above) AND that has one or more of the following characteristics; (a) Contains or has a potential to contain a hazardous atmosphere; (b) Contains a material that has the potential for engulfing an entrant; (c) Has an internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls or by a floor which slopes downward and tapers to a smaller crosssection; or (d) Contains any other recognized serious safety or health hazard. “Engulfment” means the surrounding of a person by a liquid or finely-divided (flowable) solid substance. “Entry” means the passing of any part of a person’s body through an opening into the space. “Hazardous atmosphere" means an atmosphere that may expose employees to the risk of death, incapacitation, impairment of ability to self-rescue (that is, escape unaided from a permit space), injury, or acute illness from one or more of the following causes: Flammable gas, vapor, or mist in excess of 10% of its lower flammable limit (LFL); Airborne combustible dust at a concentration that meets or exceeds its LFL; NOTE: This concentration may be approximated as a condition in which the dust obscures vision at a distance of 5 feet (1.52 m) or less. Atmospheric oxygen concentration below 19.5 percent or above 23.5 percent; Atmospheric concentration of any substance for which a dose or a permissible exposure limit is published in Subpart G, Occupational Health and Environmental Control, or in Subpart Z, Toxic and Hazardous Substances, of 29 CFR 1910 and which could result in employee exposure in excess of its dose or permissible exposure limit; NOTE: An atmospheric concentration of any substance that is not capable of causing death, incapacitation, impairment of ability to self-rescue, injury, or acute illness due to its health effects is not covered by this provision. Any other atmospheric condition that is immediately dangerous to life or health. PROGRAM ELEMENTS 1. Evaluation, inventory, and labeling 1.1 General. All confined spaces shall be evaluated to determine if they are permitrequired confined spaces. The evaluation shall be conducted with the space in its natural state (i.e without any precautions such as ventilation or isolation taken). The confined space evaluation form in appendix A shall be used. If the space is found to be a permitrequired confined space, then further evaluation will be conducted to (1) Evaluate the hazards of the space, including hazards that are created or exacerbated by the work to be performed (2) Classify the space into one of the categories described in section 1.2 Note: It is possible that a space may be classified one way under one set of entry circumstances, and another way under different circumstances (3) Collect information on the hazards to develop of safe entry procedures as described in section 2. (4) Determine whether or not employees or contractors will be permitted to enter the spaces. The decision making flow chart found in Appendix B may be consulted. 1.2 Classifying permit-required confined spaces. Once identified, all permitrequired confined spaces will be classified into one of the following classifications: University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 2 of 25 Type 1 2 3 Description Permit-required confined spaces that can not be classified as type 2 or 3. Permit-required confined spaces in which the only hazard is an actual or potential hazardous atmosphere and it can be demonstrated with documented monitoring data that continuous forced air ventilation alone is sufficient to maintain that permit space safe for entry. See 29 CFR 1910.146(c)(5). Permit-required confined spaces which pose no actual or potential atmospheric hazards and all hazards within the space are temporarily eliminated without entry into the space. In effect, the space is temporarily reclassified from “permit-required” to “non-permit required”. Control of atmospheric hazards through forced air ventilation does not constitute elimination of the hazards. See 29 CFR 1910.146(c)(7). 1.3 Inventory. The results of evaluations shall be used to develop a comprehensive, written inventory of all permit-required confined spaces and their classifications. The Permit-Required Confined Space Inventory form in Appendix C shall be used. 1.4 Decision to allow or prohibit entry into spaces. Based on the data collected during the evaluation, location management will determine if employees or contractors will be permitted to enter permit-required confined spaces. This decision may be made on a space-by-space basis, or as a “blanket policy”. Results of this decision will be listed in the inventory. If employees will not be permitted to enter permit spaces, all aspects of section 1 and section 4 of this program shall apply, as applicable. Effective measures shall be provided to ensure employees do not enter prohibited spaces. If employers will be permitted to enter permit spaces, all sections of this program shall apply, as applicable based on the classification of the space. 1.3 Restriction of entry. All entry points to permit-required confined spaces will be posted with signs reading “DANGER PERMIT-REQUIRED CONFINED SPACE, DO NOT ENTER” or similar language. 1.4 Responsibility. It is the responsibility of the Safety Coordinator to oversee the evaluation, classification, and development of the Permit-Required Confined Space inventory. University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 3 of 25 2. Entry procedures 2.1 General. The written entry procedures in appendices G, H, and I shall be utilized for entry into permit-required confined spaces. Appendix G applies to for type 1 spaces, appendix H applies to type 2 spaces, and appendix I applies to type 3 spaces. Entry procedures must always be used in conjunction with an entry permit. See section 3 of this program. 3. Entry permits and authorization 3.1 General. Entry into ANY permit-required confined space will require a written permit. The permit is intended to assure and document that all step of the procedure have been completed. 3.2 Approving the permit. Before entry begins, the entry supervisor shall sign the entry permit to authorize entry. The completed permit shall be made available to all authorized entrants or their authorized representatives, by posting it at the work site. A listing of those employees who are trained and authorized to authorize permits is found in appendix D. 3.3 Duration of the permit. The duration of the permit may not exceed the time required to complete the assigned task or job identified on the permit. The entry supervisor shall terminate entry and cancel the entry permit when: The work covered by the entry permit has been completed; or The time period covered by the permit has expired; or A prohibited or hazardous condition arises in or near the permit space. The space shall be evacuated completely and immediately when the permit is cancelled. 3.4 Retention of the permit. Each canceled entry permit shall be retained for at least one year to facilitate the review of the program. Any problems encountered during an entry operation shall be noted on the pertinent permit so that appropriate revisions to the permit space program can be made. 3.5 Permit form. The permit form found in appendix E shall be used. 4. Contractors University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 4 of 25 4.1 General. When contractors perform work that involves permit space entry, location staff and authorized representatives from the contractor organization shall conduct a pre-task meeting, to review the information found in appendix F. 4.2 Documentation. Documentation that the steps outlined above have been completed, shall be documented using the form found in Appendix F. Records shall be retained for one year, and used in the annual program review. 4.3 Responsibility. It is the responsibility of the Safety Coordinator to ensure that the requirements of this section are complied with. 5. Equipment 5.1 General. Procedures described in section 2 of this program shall outline the equipment required to work safely within Permit-Required Confined spaces (regardless of type). 5.2 Cost. All required equipment shall be provided to employees free of charge. 5.3 Maintenance and calibration. All equipment (specifically atmospheric monitoring equipment) shall be maintained, calibrated, serviced, inspected and used, as directed by the manufacturer. 5.4 Approved equipment. Equipment shall be approved for the use at hand, specifically with regard to the equipment approval for hazardous environments (i.e. spaces which may contain explosive levels of gas, dust, fibers, etc.). A statement of approval shall be clearly legible on the equipment. 6. Emergency planning and response 6.1 General. Formal emergency response plans must be developed when employees enter type 1 permit-required confined spaces. This section does not apply to type 2 or 3 spaces. Emergency planning and response measures must be documented in the entry procedures. 6.2 Designating external emergency service providers to provide emergency response. If local public safety services (i.e. local police and fire) are designated to provide confined space rescue, the following steps shall be taken. The prospective rescuer's ability to respond to a rescue summons in a timely manner, considering the hazard(s) identified, shall be evaluated. University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 5 of 25 Evaluate a prospective rescue service's ability, in terms of proficiency with rescue-related tasks and equipment, to function appropriately while rescuing entrants from the particular permit space or types of permit spaces identified; Select a rescue team or service from those evaluated that: o Has the capability to reach the victim(s) within a time frame that is appropriate for the permit space hazard(s) identified; o Is equipped for and proficient in performing the needed rescue services; o Inform each rescue team or service of the hazards they may confront when called on to perform rescue at the site; and o Provide the rescue team or service selected with access to all permit spaces from which rescue may be necessary so that the rescue service can develop appropriate rescue plans and practice rescue operations. 6.3 Designating employees to provide emergency response. If employees are designated to provide permit space rescue and emergency services, the following steps shall be taken: Provide affected employees with the personal protective equipment (PPE) needed to conduct permit space rescues safely and train affected employees so they are proficient in the use of that PPE, at no cost to those employees; Train affected employees to perform assigned rescue duties. The employer must ensure that such employees successfully complete the training required to establish proficiency as an authorized entrant; Train affected employees in basic first-aid and cardiopulmonary resuscitation (CPR). At least one member of the rescue team or service holding a current certification in first aid and CPR shall be available during entry operations; and Ensure that affected employees practice making permit space rescues at least once every 12 months, by means of simulated rescue operations in which they remove dummies, manikins, or actual persons from the actual permit spaces or from representative permit spaces. Representative permit spaces shall, with respect to opening size, configuration, and accessibility, simulate the types of permit spaces from which rescue is to be performed. 6.4 Facilitating non-entry rescue. To facilitate non-entry rescue, retrieval systems or methods shall be used whenever an authorized entrant enters a type 1 permit space, unless the retrieval equipment would increase the overall risk of entry or would not contribute to the rescue of the entrant. Retrieval systems shall meet the following requirements. Each authorized entrant shall use a chest or full body harness, with a retrieval line attached at the center of the entrant's back near shoulder level, above the entrant's head, or at another point which the employer can establish presents a profile small enough for the successful removal of the entrant. Wristlets may be used in lieu of University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 6 of 25 the chest or full body harness if it can be demonstrated that the use of a chest or full body harness is infeasible or creates a greater hazard and that the use of wristlets is the safest and most effective alternative. The other end of the retrieval line shall be attached to a mechanical device or fixed point outside the permit space in such a manner that rescue can begin as soon as the rescuer becomes aware that rescue is necessary. A mechanical device shall be available to retrieve personnel from vertical type permit spaces more than 5 feet deep 6.5 Safety Data Sheet. If an injured entrant is exposed to a substance for which a Safety Data Sheet (SDS) or other similar written information is required to be kept at the worksite, that SDS or written information shall be made available to the medical facility treating the exposed entrant. 7. Training and communication 7.1 General. Each employee covered by this program shall receive training which complies with this section. Upon completion of training, employees must have the understanding, knowledge, and skills necessary for the safe performance of the duties assigned to them. 7.2 Cost of training. Training shall be provided at no cost to the employee. 7.3 Frequency of training. Training must be provided to an employee at the time of initial assignment to a job which involves work covered by this program. Additional training must be provided whenever conditions change or when an employee’s performance indicated a need for retraining. Training updates must be repeated at intervals of not greater than one year. Training updates may be brief summaries of information included in previous training sessions. 7.4 Content of training. At a minimum, training shall consist of the following: The nature of Permit-Required Confined Space hazards that may be encountered in/around the spaces to which the employee may be exposed; The precautions required to control those hazards and maintain acceptable entry conditions; Proper calibration, operation, maintenance, inspection of all equipment involved in entry; Responsibilities of entrants, attendants, supervisors; The purpose, importance, and proper application of the entry procedures and permits; University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 7 of 25 Emergency procedures; A brief review of this program, as well as the OSHA regulation. 7.5 Records of training. Records of training shall be maintained, retained for three years. At a minimum, training records will include: the dates training was conducted; the name, title, and qualifications of the person who conducted the training; the names and job titles of employees who completed the training; and a brief summary or outline of the information that was included in the training session. Appendix J or equivalent shall be used. 7.6 Unacceptable forms of training. The following types of training, by themselves, do not constitute training, and do not comply with this program or the regulation: Giving an employee a data sheet, package insert, reference manual or any other printed material to read. Watching video or computer-delivered presentations, especially when the material in the video is not specific to the operation and hazards at hand. Any type of training which does not include an opportunity for employees to ask questions to ensure they understand the information presented to them. Audiovisuals, interactive videos, printed materials, etc., may be used as a component of the training program if they are supplemented by specific information related to the employees' job duties and related exposures, and if employees are permitted to ask questions and have them answered. 7.7 Responsibility. It is the responsibility of the Safety Coordinator to ensure that the requirements of this section are complied with. PROGRAM EVALUATION At least annually, a formal, documented review shall be conducted to ensure that the provisions of the current written program are being effectively implemented and that it continues to be effective. University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 8 of 25 APPENDIX A – CONFINED SPACE EVALUATION FORM Complete this form for each confined space. Name of space evaluated: Number of similar/identical space & location(s): Name of evaluator(s): Date of evaluation: Description of space: Results of evaluation: Not a confined space Not a Permit-Required Confined Space Permit-Required Confined Space – Type 1 Permit-Required Confined Space – Type 2 Permit-Required Confined Space – Type 3 Who will be permitted to enter? Complete this section only if the space is classified as a type 1, 2, or 3 Permit-Required Confined Space: Location (university employees) only Contractor employees only Location and/or contractors No entry will be permitted by any person Question 1. Is this area a “confined space”? Yes Yes Yes A confined space is defined as having all of the characteristics listed below. If you conclude that this area is not a confined space, then go to the “results of evaluation” section above and check “not a confined space”. STOP. If you conclude that this area is a confined space, then continue to the next question. No No No Is the space large enough and so configured that a person can bodily enter and work? Does the space have a limited or restricted means of entry or exit? Is the space not designed for continuous human occupancy? Questions 2. Is this area a “Permit-Required Confined Space”? Yes A permit-required confined space is defined as a confined space (see question 1) which also has one or more of the characteristics below. If you conclude that this area is not a permit-required confined space, then go to the “results of evaluation” section above and check “not a permit-required confined space”. STOP. If you conclude that this area is a permit-required confined space, then continue to the next question. No Does the space contain, or have the potential to contain a hazardous atmosphere (i.e. oxygen deficiency, explosive limits, carbon monoxide, hydrogen sulfide), or pipes, ducts or other entry points for potentially hazardous substances, or will volatile chemicals be used, or will painting, sealing, or other work practices create a breathing hazard? Specify hazards: Possible oxygen deficiency from bacteria and or decaying organic matter. Hydrogen Sulfide or Methane possible but unlikely. Yes No Does the space contain an engulfment hazard (i.e. sand, grain, water)? University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 9 of 25 Specify hazards: Possibility of insignificant amount of water from seepage, etc. Yes No Does the space have inwardly converging walls that taper downward to a smaller crosssection, or floors that slope downward that could lead to entrapment or asphyxiation? Specify hazards: Yes No Does the space contain other recognized serious hazards, such as: Mechanical hazards such as moving parts, unguarded machinery, etc. Exposed or vulnerable electrical wires or electrical equipment Gas or chemical lines Special hazards related to elevation or falling Temperature extremes/heat stress Other Specify hazards: Questions 3. Is this area a Type 2 “Permit-Required Confined Space”? A type 2 permit-required confined space is defined as a permit-required confined space (see question 1 and 2) which meets all of the characteristics below. If you conclude that this area is not a type 2 permit-required confined space, then continue to question 4. If you conclude that this area is a type 2 permit-required confined space, then go to the “results of evaluation” section above and check “Permit-Required Confined Space – Type 2”. STOP. Note that the conditional instructions found in the 2nd and 3rd bullets in questions 3 and 4 are inconsistent with previous questions. Please read all questions and instructions carefully. Yes No Yes No Yes No The only hazard of the permit-required confined space is a hazardous or potentially hazardous atmosphere. Continuous forced air ventilation alone is sufficient to maintain that permit space safe for entry; There is a formal documented history of evaluations that support the conclusion above. Questions 4. Is this area a Type 3 “Permit-Required Confined Space”? Yes A type 3 permit-required confined space is defined as a permit-required confined space (see question 1 and 2) which meets all of the characteristics below. If you conclude that this area is not a type 3 permit-required confined space, then continue to question 5. If you conclude that this area is a type 3 permit-required confined space, then go to the “results of evaluation” section above and check “Permit-Required Confined Space – Type 3”. STOP. Note that the conditional instructions found in the 2 nd and 3rd bullets in questions 3 and 4 are inconsistent with previous questions. Please read all questions and instructions carefully. No The space has no actual or potential atmospheric hazards. University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 10 of 25 Yes No All hazards within the space can be positively controlled or eliminated temporarily without entry into the space. For example, by locking out augers, and other such mechanical hazards. Questions 5. Is this area a Type 1 “Permit-Required Confined Space”? A type 1 permit-required confined space is defined as a permit-required confined space (see question 1 and 2) which DOES NOT meet conditions for type 2 or 3 (see questions 3 and 4). If you have identified this space as a permit-required confined space (see questions 1 and 2), AND have concluded that it is not a Type 2 or Type 3, then go to the “results of evaluation” section above and check “Permit-Required Confined Space – Type 1”. STOP. University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 11 of 25 APPENDIX B – CONFINED SPACE EVALUATION DECISION MAKING FLOW CHART University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 12 of 25 APPENDIX C – INVENTORY OF PERMIT-REQUIRED CONFINED SPACES Identity of space Hazards Classification (see section 1) 13 Entry allowed by location employees? Entry allowed by other employers (i.e. contractors)? Comments APPENDIX D – EMPLOYEES TRAINED AND AUTHORIZED TO AUTHORIZE CONFINED SPACE ENTRY PERMITS Employee name University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 14 of 25 Job title Date of most recent training (authorization expires one year after training) APPENDIX E – PERMIT REQUIRED CONFINED SPACE ENTRY PERMIT PART 1. COMPLETE FOR ALL ENTRIES REGARDLESS OF TYPE General Information Space to be entered: Permit start date/time Name of entry supervisor (if required in procedure): Expires date/time: Purpose of entry/Work to be performed: Name of attendant (if required in procedure): Name(s) of entrants: PART 2. COMPLETE FOR ENTRIES INTO TYPE 1 OR TYPE 2 SPACES Initial pre-entry atmospheric check Person conducting test Time Instrument(s) used To be measured: Oxygen (O2): ________ Hydrogen Sulfide (H2S): ________ Carbon Monoxide (CO): ________ Lower Explosive Limit (LEL): ________ Other __________________ : ________ Other __________________ : ________ Other __________________ : ________ Acceptable range 19.5%-23.5% Less than 10 ppm Less than 35 ppm Less than 10% ________ ppm ________ ppm ________ ppm Atmospheric monitoring during entry Time Oxygen 19.5-23.5 Hydrogen Sulfide CO <10 ppm LEL <10% <35 ppm Other Other Other PART 3. COMPLETE FOR ALL ENTRIES REGARDLESS OF TYPE Preparation for entry (See written procedure for requirements) Entrants protected from objects or tools falling into the space? Done NR All entrants wearing lifelines and body harness? Harness attached to appoint outside the space? Mechanical retrieval being used for vertical entries over five feet? Done NR Attendant stationed at entry point? Verbal and nonverbal communication established? Attendant has means to call for emergency assistance? Done NR University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 15 of 25 Continuous mechanical forced air ventilation in place? Fans/blowers are explosion proof when necessary? Done NR Direct-reading instruments in use to monitor atmospheric hazards? All employees provided with an opportunity to observe testing? Done NR Whenever possible, space has been properly isolated to prevent hazards from entering the space (i.e. water, grain, hazardous atmospheres, etc.)? Done NR Fire prevention measures have been taken? No smoking permitted in or around the space? Hot work permit is completed if welding or open-flame or spark-producing work is to be conducted? Calibrated LEL meter being used? Properly rated electrical devices being used if hazardous conditions are possible? Done NR All mechanical and other hazards locked and tagged out? Done NR Emergency procedure reviewed with all employees? Means to quickly call for help are provided? Done NR Done NR All fall hazards within the space have been eliminated by using fall arrest systems, temporary railings, or similar? Other – Other – Done NR Other – Done NR Other – Done NR NR – Not required by procedure PART 4. COMPLETE FOR ALL ENTRIES REGARDLESS OF TYPE. Supervisor’s authorization I have reviewed the relevant confined space entry procedure and verified that all necessary steps to prepare for entry have been taken. I authorize this work to begin at this point. Entry supervisor: ____________________________________________ Date/Time: _________________ PART 5. COMPLETE FOR ALL ENTRIES REGARDLESS OF TYPE. Conclusion – complete this section after work has concluded Permit terminated because: _____ Work was completed as planned _____Prohibited condition/emergency Any event that would merit a review confined space program/procedure? Yes No Was a mandatory close-out meeting held with contactors? Yes No NA University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 16 of 25 APPENDIX F – INFORMATION PROVIDED TO CONTRACTORS A pre-task meeting shall be conducted prior to allowing contractors to perform any work which involves entry into permit-required confined spaces. At a minimum, the pre-task meeting shall be attended by University location staff and at least one authorized representative of the contractor organization/company. The final item in the checklist below must be completed at the conclusion of the work. Inform the contractor that the workplace contains permit-required confined spaces and the contractor is required to have a permit-required confined space program meeting the requirements of 29 CFR 1910.146. Contractor use of the University’s program is not allowable; Conduct a review of the contractor’s confined space entry program, procedures and training records to determine if they are adequate. OHS and/or DEHS are available to assist with this review; Apprise the contractor of the elements, including the hazards identified and the location’s experience with the space, that make the space in question a permit space; Apprise the contractor of any precautions or procedures that have been implemented for the protection of employees in or near permit spaces where contractor personnel will be working; Coordinate entry operations with the contractor, when both university and contractor personnel will be working in or near permit spaces; and Debrief the contractor at the conclusion of the entry operations regarding the permit space program followed and regarding any hazards confronted or created in permit spaces during entry operations. Complete Complete Complete Complete Complete Complete I acknowledge that the information above has been communicated between the parties. ____________________________ ____________________________ University staff (printed name) Contractor staff representative (printed name) ____________________________ ____________________________ University staff (signature) Contractor staff representative (signature) ____________________________ ____________________________ Date Name of contractor organization/company ____________________________ Date University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 17 of 25 APPENDIX G – CONFINED SPACE ENTRY PROCEDURE FOR TYPE 1 SPACES This procedure lists the steps which must be taken prior to, and during entry into type 1 spaces. This procedure establishes “acceptable entry conditions”. Entry may not occur unless all of these conditions are met. All entrants, attendants and supervisors must review this procedure prior to entering. PERMIT. A written entry permit must be filled out and authorized by an entry supervisor, prior to entering the space. The purpose of the permit is to verify and document that all steps in this procedure have been completed. PROTECTING ENTRANTS FROM OUTSIDE HAZARDS. If entrants may be struck by objects such as tools falling into the space (for example when working in manholes), then the entry point must be guarded or barricaded. LIFELINE AND HARNESS. To facilitate non-entry emergency rescue of entrants, each entrant must wear an appropriate lifeline and body harness during entry. The lifeline must be attached to a fixed point outside the permit space. The lifeline MAY NOT BE ATTACHED TO A VEHICLE. If entrants are working in spaces greater than five vertical feet below the entry point, then a MECHANICAL retrieval method (winch) must be used. ATTENDANT. A trained and authorized attendant must be stationed at the entry point to the confined space. The attendant must be in constant communication with all entrants and must have the ability to summon rescuers when needed. VENTILATION AND MONITORING. Continuous forced air ventilation must be provided prior to and during the entry. Mechanical means must be used to ventilate the space. When/If explosive or flammable atmospheres are possible, all ventilation equipment must be properly rated. In addition to ventilation, the atmosphere within the space must be continually monitored with a properly calibrated direct-reading instrument. This instrument must be capable of monitoring for gases and vapors which are anticipated in the space. Results of monitoring must be documented on the permit form. Applicable employees must be provided with an opportunity to observe/witness all ventilation procedures and monitoring results. ISOLATING THE SPACE. If possible, feedlines, pipelines, conveyors, passageways, tunnels, or any other condition or equipment which may allow hazards to enter the space must be positively controlled prior to entry. FIRE AND EXPLOSION PREVENTION. No smoking is permitted in the permit space, or within 10 feet of any entry point to the permit space. Spark producing or open University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 18 of 25 flame work may only be conducted in the space, or within 10 feet of the entry point of the space, if a hot work permit has been completed and authorized. All electrical equipment must be rated for use in explosive/flammable atmospheres if dangerous levels of combustible dust or flammable gases or vapors are possible. A properly calibrated directreading LEL meter must be used as outlined elsewhere in this procedure. CONTROLLING MECHANICAL AND OTHER HAZARDS WITHIN THE SPACE. All mechanical equipment and other hazards within the space must be locked and tagged out of service, or otherwise positively controlled, using approved lockout/tagout procedures. When equipment can not be locked and tagged out of service (for example, when aligning belts), a stand by worker must be stationed at the power control for the machine to open the circuit in case of emergency. FALL HAZARDS WITHIN THE SPACE. Any exposure to a fall of more than four feet must be eliminated by having all entrants wear appropriate fall protection equipment or by the installation of temporary railings, etc. Note that this rule applies to hazards within the space. EMERGENCY PROCEDURES. An emergency may be declared by an entrant, attendant, or supervisor under any of the following conditions: Failure of any tool or equipment such as ventilation or gas meter. A condition that requires an attendant to leave the work site. Loss of communication between an attendant and entrant(s). An atmospheric hazard such as unsafe level of a contaminant or oxygen deficiency or enrichment A hazard outside of the space that might endanger entrants, such as severe weather. Any other condition that might create a hazard for entrants, or any other employee. In the event of an emergency, the permit is revoked and all entrants must immediately evacuate the space. If rescue is required, the attendant and/or supervisor will provide NON-ENTRY RESCUE and will summon the local fire department if needed. University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 19 of 25 APPENDIX H – CONFINED SPACE ENTRY PROCEDURE FOR TYPE 2 SPACES This procedure lists the steps which must be taken prior to, and during entry into type 2 spaces identified above. This procedure establishes “acceptable entry conditions”. Entry may not occur unless all of these conditions are met. All entrants, attendants and supervisors must review this procedure prior to entering. PERMIT. A written entry permit must be filled out and authorized by an entry supervisor, prior to entering the space. The purpose of the permit is to verify and document that all steps in this procedure have been completed. PROTECTING ENTRANTS FROM OUTSIDE HAZARDS. If entrants may be struck by objects such as tools falling into the space (for example when working in manholes), then the entry point must be guarded or barricaded. LIFELINE AND HARNESS. Lifelines/harnesses are not required for type 2 spaces. ATTENDANT. Attendants are not required for type 2 spaces. VENTILATION AND MONITORING. Continuous forced air ventilation must be provided prior to and during the entry. Mechanical means must be used to ventilate the space. When/If explosive or flammable atmospheres are possible, all ventilation equipment must be properly rated. In addition to ventilation, the atmosphere within the space must be continually monitored with a properly calibrated direct-reading instrument. This instrument must be capable of monitoring for gases and vapors which are anticipated in the space. Results of monitoring must be documented on the permit form. Applicable employees must be provided with an opportunity to observe/witness all ventilation procedures and monitoring results. ISOLATING THE SPACE. Type 2 spaces do not have the potential for this type of hazard. There should be no need to isolate the space. If the space has this potential it should be reevaluated and reclassified. FIRE AND EXPLOSION PREVENTION. No smoking is permitted in the permit space, or within 10 feet of any entry point to the permit space. Spark producing or open flame work may only be conducted in the space, or within 10 feet of the entry point of the space, if a hot work permit has been completed and authorized. All electrical equipment must be rated for use in explosive/flammable atmospheres if dangerous levels of combustible dust or flammable gases or vapors are possible. A properly calibrated directreading LEL meter must be used as outlined elsewhere in this procedure. University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 20 of 25 CONTROLLING MECHANICAL AND OTHER HAZARDS WITHIN THE SPACE. Type 2 spaces do not have the potential for this type of hazard. There should be no need to isolate the space. If the space has this potential it should be reevaluated and reclassified. FALL HAZARDS WITHIN THE SPACE. Type 2 spaces do not have potential for this type of hazard. There should be no need for fall protection. If the space has this potential, it should be reevaluated and reclassified. EMERGENCY PROCEDURES. An emergency may be declared by an entrant, attendant, or supervisor under any of the following conditions: Failure of any tool or equipment such as ventilation or gas meter. A condition that requires an attendant to leave the work site. Loss of communication between an attendant and entrant(s). An atmospheric hazard such as unsafe level of a contaminant or oxygen deficiency or enrichment A hazard outside of the space that might endanger entrants, such as severe weather. Any other condition that might create a hazard for entrants, or any other employee. In the event of an emergency, the permit is revoked and all entrants must immediately evacuate the space. If rescue is required, the attendant and/or supervisor will provide NON-ENTRY RESCUE and will summon the local fire department if needed. University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 21 of 25 APPENDIX I – CONFINED SPACE ENTRY PROCEDURE FOR TYPE 3 SPACES This procedure lists the steps which must be taken prior to, and during entry into type 3 spaces identified above. This procedure establishes “acceptable entry conditions”. Entry may not occur unless all of these conditions are met. All entrants, attendants and supervisors must review this procedure prior to entering. PERMIT. A written entry permit must be filled out and authorized by an entry supervisor, prior to entering the space. The purpose of the permit is to verify and document that all steps in this procedure have been completed. PROTECTING ENTRANTS FROM OUTSIDE HAZARDS. If entrants may be struck by objects such as tools falling into the space (for example when working in manholes), then the entry point must be guarded or barricaded. LIFELINE AND HARNESS. Lifelines/harnesses are not required for type 3 spaces. ATTENDANT. Attendants are not required for type 3 spaces. VENTILATION AND MONITORING. Type 3 spaces do not have the potential for atmospheric hazards. There should be no need to ventilate or monitor the atmosphere within the space. If the space has this potential it should be reevaluated and reclassified. ISOLATING THE SPACE. If possible, feedlines, pipelines, conveyors, passageways, tunnels, or any other condition or equipment which may allow hazards to enter the space must be positively controlled prior to entry. FIRE AND EXPLOSION PREVENTION. No smoking is permitted in the permit space, or within 10 feet of any entry point to the permit space. Spark producing or open flame work may only be conducted in the space, or within 10 feet of the entry point of the space, if a hot work permit has been completed and authorized. All electrical equipment must be rated for use in explosive/flammable atmospheres if dangerous levels of combustible dust or flammable gases or vapors are possible. A properly calibrated directreading LEL meter must be used as outlined elsewhere in this procedure. CONTROLLING MECHANICAL AND OTHER HAZARDS WITHIN THE SPACE. All mechanical equipment and other hazards within the space must be locked and tagged out of service, or otherwise positively controlled, using approved lockout/tagout procedures. When equipment can not be locked and tagged out of service (for example, when aligning belts), a stand by worker must be stationed at the power control for the machine to open the circuit in case of emergency. FALL HAZARDS WITHIN THE SPACE. Any exposure to a fall of more than four feet must be eliminated by having all entrants wear appropriate fall protection equipment University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 22 of 25 or by the installation of temporary railings, etc. Note that this rule applies to hazards within the space. EMERGENCY PROCEDURES. An emergency may be declared by an entrant, attendant, or supervisor under any of the following conditions: Failure of any tool or equipment such as ventilation or gas meter. A condition that requires an attendant to leave the work site. Loss of communication between an attendant and entrant(s). An atmospheric hazard such as unsafe level of a contaminant or oxygen deficiency or enrichment A hazard outside of the space that might endanger entrants, such as severe weather. Any other condition that might create a hazard for entrants, or any other employee. In the event of an emergency, the permit is revoked and all entrants must immediately evacuate the space. If rescue is required, the attendant and/or supervisor will provide NON-ENTRY RESCUE and will summon the local fire department if needed. University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 23 of 25 APPENDIX J – PERMIT-REQUIRED CONFINED SPACE SAFETY TRAINING DOCUMENTATION Training Date Time Location Trainer Training outline Definition of confined space and permit-required confined spaces Hazards of permit-required confined spaces An overview of relevant OSHA regulations Classification system (type 1, 2, and 3) A review of the permit-required confined spaces present, including results of hazard evaluation, their classification, whether or not entry is permitted, etc. The procedure/permit system Responsibilities of entrants, attendants, supervisors, etc. Emergency procedures Other topics discussed Employee name (Print) Employee signature Job title X.500 Initial at beginning of session Initial at conclusion of session Employee name (Print) Employee signature Job title X.500 Initial at beginning of session Initial at conclusion of session Employee name (Print) Employee signature Job title X.500 Initial at beginning of session Initial at conclusion of session Employee name (Print) Employee signature Job title X.500 Initial at beginning of session Initial at conclusion of session University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 24 of 25 Employee name (Print) Employee signature Job title X.500 Initial at beginning of session Initial at conclusion of session Employee name (Print) Employee signature Job title X.500 Initial at beginning of session Initial at conclusion of session Employee name (Print) Employee signature Job title X.500 Initial at beginning of session Initial at conclusion of session Employee name (Print) Employee signature Job title X.500 Initial at beginning of session Initial at conclusion of session Employee name (Print) Employee signature Job title X.500 Initial at beginning of session Initial at conclusion of session Employee name (Print) Employee signature Job title X.500 Initial at beginning of session Initial at conclusion of session Employee name (Print) Employee signature Job title X.500 Initial at beginning of session Initial at conclusion of session University of Minnesota Enter Department Name:________ Permit-Required Confined Space Entry Program Revised Enter Date Here:_______________ Page 25 of 25