NZQA unit standard 24920 version 2

advertisement

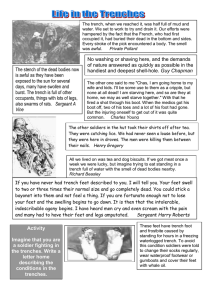

NZQA Expiring unit standard 24920 version 2 Page 1 of 5 Title Excavate and lay pipes, and reinstate trench for water reticulation Level 3 Purpose Credits 16 People credited with this unit standard are able to: set out a pipe route using control points according to the specifications and organisational procedures; assess the requirements of the job, and order resources; undertake open cut excavation in preparation for pipe installation, backfill, assess and implement dewatering, and assess and notify trench stability; check and form trench depth, grade and base in preparation for pipe installation; transport and store pipes, install bedding and pipe, and compact backfill; test the completed pipeline section; and reinstate trench surface according to specification. This unit standard is for people who work on water, or wastewater, or stormwater reticulation systems, which collectively make up water reticulation services. Classification Water Industry > Water Reticulation Available grade Achieved Explanatory notes 1 References Legislation relevant to this unit standard includes but is not limited to the Health and Safety in Employment Act 1992, and Resource Management Act 1991. Approved Code of Practice for Excavation and Shafts for Foundations, published by Occupational Safety and Health Service, Department of Labour, http://www.osh.govt.nz. 2 Definitions Specification – the drawings and specification setting out the position and standards of the proposed work. Organisational procedures – instructions to staff, and procedures which are documented in memo or manual format and are available in the workplace. These requirements include but are not limited to – site specific requirements, manufacturers’ specifications, product quality specifications, and legislative or regulatory requirements. 3 Assessment The pipeline must be at least 25mm in diameter, and at least 10 metres in length. The pipeline may be a gravity pipeline or a pressure pipeline, and be part of a reticulation system. Pipe materials must be those accepted by the owner of the reticulation system. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 24920 version 2 Page 2 of 5 Outcomes and evidence requirements Outcome 1 Set out a pipe route using control points according to specifications and organisational procedures. Evidence requirements 1.1 The route of the pipeline is checked for availability in terms of other services and surface use. Range 1.2 all underground services, traffic use, surface cover options. The route of the pipeline is set out using centre line or offset marks in terms of position. Outcome 2 Assess the requirements of the job, and order resources. Range situations – routine, emergency. Evidence requirements 2.1 The resource and documentation requirements of the job are assessed in accordance with organisational procedures. Range resources include but are not limited to – materials, staff, plant; documentation includes but is not limited to – road opening notice. 2.2 Resources are sourced and obtained in accordance with organisational procedures. 2.3 The opportunities for contamination during new pipeline construction are described in terms of water quality risks, and methods to reduce these risks. Range includes but is not limited to – pipe storage, site cleanliness, hygiene facilities, trench inundation, pipe plugs, flushing, disinfection. Outcome 3 Undertake open cut excavation in preparation for pipe installation, backfill, assess and implement dewatering, and assess and notify trench stability. Evidence requirements 3.1 Excavation is carried out on line, and in accordance with grade and organisational procedures. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 24920 version 2 Page 3 of 5 3.2 Excavation avoids interference with other services and organisational procedures. 3.3 Excavated material is assessed for suitability for backfill, and suitable material ordered in accordance with organisational procedures. 3.4 Site is assessed for dewatering, and dewatering is implemented, in accordance with organisational procedures. 3.5 Trench stability is assessed, and requirements for trench support are identified, in accordance with organisational procedures. Outcome 4 Check and form trench depth, grade and base in preparation for pipe installation. Evidence requirements 4.1 The trench depth is checked according to specifications and site constraints. 4.2 The trench sub-grade is checked for soft spots in accordance with the specification and organisational procedures. Range 4.3 one of – visual, penetrometer tests. Any soft spots in the trench sub-grade are assessed and corrected in accordance with organisational procedures. Outcome 5 Transport and store pipes, install bedding and pipe, and compact backfill. Evidence requirements 5.1 Pipes are transported and stored in accordance with manufacturer’s instructions. 5.2 Bedding is placed in the trench, and compacted in accordance with the plan and specification. 5.3 Pipes are lifted, and placed into the trench in accordance with manufacturer’s instructions. 5.4 Pipe bends, fittings, joints, and anchoring are installed according to specification. 5.5 Pipes are surrounded with compacted bedding material in accordance with the specification. 5.6 Backfilling is compacted in layers according to specification. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 24920 version 2 Page 4 of 5 Outcome 6 Test the completed pipeline section. Evidence requirements 6.1 The pipeline is tested in accordance with the specification. may include but is not limited to – low pressure air tests, water tests, high pressure water tests; evidence is required for at least one. Range Outcome 7 Reinstate trench surface. Range may include but is not limited to – grass verge, chipseal, concrete, asphalt; evidence is required for at least one. Evidence requirements 7.1 Trench surface is reinstated according to specification. Replacement information This unit standard replaced unit standard 19203. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 19 September 2008 31 December 2016 Review 2 21 July 2011 31 December 2016 Consent and Moderation Requirements (CMR) reference 0179 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 24920 version 2 Page 5 of 5 Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016