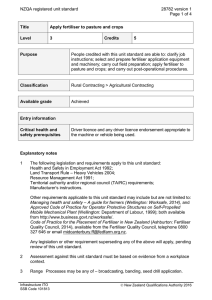

Describe fertiliser spreaders and fertiliser spreading, and demonstrate driving skills

advertisement

19374 version 2 Page 1 of 4 Describe fertiliser spreaders and fertiliser spreading, and demonstrate driving skills Level 4 Credits 4 Purpose People credited with this unit standard are able to: describe the technical design of fertiliser spreaders and implications for fertiliser spreading; describe fertiliser spreader certification; select fertiliser spreader machinery settings and demonstrate driving skills; and describe the consequences of poor spreading. Subfield Agriculture Domain General Agriculture Status Registered Status date 19 April 2002 Date version published 20 May 2008 Planned review date 31 December 2010 Entry information Open. Accreditation Evaluation of documentation and visit by NZQA, industry and teaching professional in the same field from another provider. Standard setting body (SSB) Primary Industry Training Organisation Accreditation and Moderation Action Plan (AMAP) reference 0052 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 The reference for this unit standard is The Spreadmark Code of Practice. Refer to this document for acceptable use of industry specific terms, unless stated otherwise. The Spreadmark Code of Practice is updated regularly and is available from Federated Farmers, PO Box 414, Ashburton. 2 Legislation relevant to this unit standard includes but is not limited to the – Agricultural Compounds and Veterinary Medicines Act 1997, Hazardous Substances and New Organisms Act 1996, Health and Safety in Employment Act 1992, Land Transport Act 1998, Resource Management Act 1991, and their subsequent amendments. New Zealand Qualifications Authority 2016 19374 version 2 Page 2 of 4 Elements and performance criteria Element 1 Describe the technical design of fertiliser spreaders and implications for fertiliser spreading. Performance criteria 1.1 Hopper design is described in terms of the varying levels of hopper loadings and feed. 1.2 Drag chain and belt design is described in terms of the use of mechanical and computer systems to control flow rate. 1.3 Disc design and speed is described in terms of control systems. 1.4 Spreader patterns are described in terms of bout width, fertiliser particle size, and machine set-up. 1.5 The evenness of fertiliser spreading is described in terms of the transverse and longitudinal Coefficient of Variation. 1.6 Performance is described in terms of fertiliser build-up and poor load distribution. Element 2 Describe fertiliser spreader certification. Performance criteria 2.1 Spreader certification is described in terms of pre-calibration of fertiliser spreader machinery. 2.2 Spreader certification is described in terms of the procedures for calibration of fertiliser machinery, and the role of the operator/driver in the procedure. 2.3 Spreader certification is described in terms of post-calibration field tests for field adjustment of fertiliser spreader machinery. Element 3 Select fertiliser spreader machinery settings, and demonstrate driving skills. Performance criteria 3.1 Settings selected match fertiliser characteristics, application rate, and bout width. New Zealand Qualifications Authority 2016 19374 version 2 Page 3 of 4 3.2 Driving techniques demonstrated maximise performance and minimise vehicle damage in relation to the terrain and surface conditions. 3.3 Selection of areas of operation and terrain match vehicle loading. 3.4 Safety precautions demonstrated before and during spreading, and while servicing machinery are in accordance with The Spreadmark Code of Practice and legislative requirements. Range equipment, procedures. 3.5 Negotiation of terrain and obstacles while spreading fertiliser ensures optimum fertiliser spread, and avoids damage to property and equipment. 3.6 Remedial action is taken following indicators of malfunctions, in accordance with manufacturer’s recommendations. 3.7 Techniques are implemented to minimise possible environmental damage. Range includes but is not limited to – cut-off systems, riparian strips, buffer and soakage. Element 4 Describe the consequences of poor spreading. Performance criteria 4.1 The consequences of poor spreading including apply excessive amounts of nutrients are described in terms of the environmental consequences. 4.2 The consequences of poor spreading are described in terms of client confidence and company reputation. 4.3 The consequences of poor spreading are described in terms of civil and criminal liability. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. New Zealand Qualifications Authority 2016 19374 version 2 Page 4 of 4 Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Primary Industry Training Organisation standards@primaryito.ac.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016