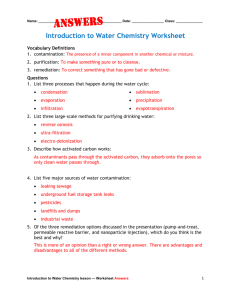

Interpretation of RSA93 and IRR99

Royal Society of Chemistry

Radiochemistry Seminar

7th April 2008

Interpretation of RSA93 and IRR99

Practical experiences in a pharmaceutical radiochemistry laboratory

Interpretation of RSA93 and IRR99 - practical experiences in a pharmaceutical radiochemistry lab

Introduction

Acknowledgement : -

Content of this presentation refers to isotope chemistry at AstraZeneca

Alderley Park, Macclesfield Cheshire

Similar activities are carried out at AZ Charnwood, Loughborough, Leics.

SHE Adviser role - two requirements to maintain ' Licence to Operate'

Protection of AZ staff from exposure - compliance with IRR99

Protection of AZ's business interests - compliance with RSA93

Interpretation of IRR99 and RSA93 - practical experiences in a pharmaceutical radiochemistry lab

Introduction

What aspects of managing work with long half-life radioisotopes can help control "sentencing and disposal" ?

1. Compliance with principles required for Registrations and Authorisations

2. Following 'best practice' with respect to : -

Laboratory design.

Management of risk associated with activities in the lab.

3. Laboratory life-cycle management including decommissioning.

1. Registrations and Authorisations

RSA3 and Best Practicable Means (BPM)

Radioactive Substances Act Guidance (RASAG) Chapter 4 - Generic Issues

BPM principles : -

• Minimise radioactive waste creation and disposal.

• Arrive at the lowest radiation dose to the public.

• Proportionality applies ....... < 300 μSv/yr.

• ALARP culture which allows for potential conflict regarding worker exposure.

1. Registrations and Authorisations

Detailed requirements for Authorisation applications (Section F4)

EA Authorisation applications require statements about.....

•

The existence and scope of a Management System and organisational structure for compliance with authorisation requirements.

•

•

An indication of the resources available to achieve compliance.

•

Assurance that consultation with an RPA or other qualified expert is available if needed e.g. environmental impact assessment.

•

Assurance that written operating procedures are in place to cover accumulation and disposal of radioactive waste

That there are arrangements for adequate supervision of disposal of radioactive waste.

.........these become conditions attached to the Authorisation when granted.

1. Registrations and Authorisations

Detailed guidance on BPM (RASAG Chapter 4)

Guidance on issues relevant to 14 C and 3 H use in radiosynthesis labs

2. Synthetic isotope chemistry lab

General information

AZ Alderley Park isotope chemistry lab was completely rebuilt in 2007.

•

6 staff responsible for incorporating 14 C and 3 H labels into drug candidates for

Lead Development , in vivo and clinical studies.

•

The lab accounts for 75% - 95% of Site's Registration for 14 C (160 GBq).

• Syntheses with up to 20 GBq 14 C at a time.

• Main contributor to 4 GBq drain ( monthly ) and 40 GBq solid ( annual) Site

Authorisation limits.

•

The lab accounts for approx. 99.9 % of Site's Registration for 3 H (25 TBq).

•

Tritium generator with potential for ~15 TBq 3 H generation.

• Main contributor to 90 GBq drain ( monthly ), 40 GBq solid ( annual) and 200 GBq gas

( daily ) Site Authorisation limits.

• The laboratory is the main storage location for radioactive material in stand-alone fridges / freezers.

2. Synthetic isotope chemistry lab

Design features

There is a zonal floor plan which segregates on a radioactivity hazard basis ; cold --> hot --> hottest.

Highest hazard areas are designated Controlled ..... 'special procedures' are necessary to restrict the possibility of significant exposure.

The primary control principle is containment using LEV.

LEV is dedicated to radionuclide type resulting in 'zoned' exhaust ductwork and roof discharge.

There are designated

- radioactive material storage areas.

- waste storage and waste processing procedures.

- waste disposal drains - shortest runs and high run-off angles to main downpipe.

- change / PPE / wash / hand/foot monitoring in dedicated entrance cubicle.

There is a rigorous program (regularly audited) of contamination monitoring.

The laboratory uses a computerised source accounting system which accurately tracks acquisition, storage, use and disposal of radioactive materials.

Where there is the risk of contamination accumulation e.g. in drains and exhaust ductwork, warning labels are attached.

2. Synthetic Isotope chemistry lab

Disposal / fate of 14 C and 3 H waste from AZ AP or release

River Bollin

3. Isotope chemistry lab decommission

General information

The original isotope chemistry laboratory was built in 1985.

With 14 C and 3 H radionuclides used in large quantities over ~ 20 years it was reasonable to expect some contamination of : -

• items of laboratory equipment

• fume hoods, extract ductwork, extract fans and roof discharge stacks

• drains and possibly

• laboratory walls / floors / ceiling soffits / benches and other furniture.

Historical records and knowledge !

3. Isotope chemistry lab decommission

Definitions and Principles ......

Definitions

Contaminated items and or waste material can be regarded as Very Low Level

(radioactive) Waste - VLLW Category 2 if : -.

• The sum of all 14 C and 3 H in 0.1m

3 of refuse is < 4 MBq and < 0.4 MBq in any one item and there are no other radionuclides.

• Above these levels the material must be disposed of as radioactive waste.

Principles followed for decommissioning

- Waste to be streamed as VLLW if the definition criteria were met.

- If the VLLW criteria were not met consider

• decontamination and or

• size-reduction

But with due regard to safety, acceptability to Disposal Provider, and cost.

3. Isotope chemistry lab decommission

Process......

Process

• Lab staff dispose of unwanted stored radioactive samples (£!) and relocate the store.

• A survey

* was commissioned of equipment and 'reasonably accessible' work areas - benches, floors, walls, fume hood surfaces etc.,

• where contamination was found, decontamination was attempted.

• location of non-removeable contamination was recorded.

• estimate whether VLLW. * hand-held β monitor and swabs

• Lab staff hand over the area to Decommission Project Team.

• Project Team follow a programmed strip-out with monitoring / decontamination / monitoring cycles, as areas became accessible ductwork, drains etc.,

• where contamination found, attempt decontamination.

• estimate whether VLLW.

3. Isotope chemistry lab decommission

Flow schematic

3. Isotope chemistry lab decommission

Examples of contamination revealed by the survey

Initial survey revealed areas of removable and nonremoveable contamination on a range of fixtures and fittings.

Bound contaminated on fixtures and fittings was logged prior to strip-out to help waste stream categorisation.

3. Isotope chemistry lab decommission

Examples of contamination revealed as strip-out progressed.

As strip-out progressed more contaminated items were found.

No surprises - what was found was typical of an isotope chemisry lab.

Some contamination was removable by cleaning.

3. Isotope chemistry lab decommission

Final inventory of contaminated material (not VLLW).

• 11 x sections of plastic or steel exhaust ductwork, ranging from 1.0 to 2.7m L x 0.34m D.

0.75 - 10.5 MBq contamination, mixture of 14 C and 3 H.

• 15 x sections of roof discharge stacks ~ 2m L x 0.5m D.

0.5 - 1.9 MBq contamination, mixture of 14 C and 3 H.

• 11 x extract fans with motors attached.

• Various fixtures - trespa worksurfaces, vinyl flooring, baffle plates, sink units, flow cabinets etc totalling ~ 35 MBq 14 C and 3 H.

• Stainless steel sonicator bath 2.1 MBq

• Stainless steel solvent bin 0.8 MBq

• Lengths of vulcathene and copper drains

* from fume hoods and sinks.

• All items were polythene wrapped and stored in 2 x secure 40m 3 skips.

*

An 8m length of contaminated ductwork 'disappeared' requiring notification of the

Regulators and a costly investigation.

3. Isotope chemistry lab decommission

Trials and tribulations ...........

At this point AZ's usual disposal provider informed that, contrary to an earlier agreement they would not take the radioactive waste - items were too large for incineration.

Dialogue initiated with the EA about options available.

During on-going dialogue, EA Inspector visited AP on other routine business, 2 weeks prior to the end of the Site's 12 week / 2 m 3 radioactive waste accumulation limit.

Questions were asked about the skip contents which resulted in a Warning Letter

- accumulation quantity and period exceeded.

No further action taken and temporary extention (18 wks / 80m 3 ) to Authorisation was granted

3. Isotope chemistry lab decommission

Trials and tribulations ...........

Completion of the Project ;

• A contractor was commissioned to size-reduce to a level acceptable to

Disposal Provider, 200 l drum size target.

• Negative pressure isolation tent set up, full PPE including RPE.

• Filled 30 wheelie bins, 2 x articulated lorry shipments.

• Required final contamination monitoring / clean-up of tented area.

• Required final contamination monitoring / clean-up of 2 x 40m 3 skips.

• 8 weeks extension to original Project time-framework.

• cost = £ substantial

Summary

• Use the guidance available when applying for EA Registrations and

Authorisations.

• Consider radionuclide 'cradle to grave' issues in relation to

• lab design

• operational activities

• waste generation and disposal processing

• planning in anticipation of decommissioning work

• Effectively manage compliance for 'Licence to Operate'

• interface with Regulators

• anticipate and try to have contingency measures at hand

• Learn from experience !

![tutorial #14 [nuclear physics and radioactivity] .quiz](http://s3.studylib.net/store/data/008407305_1-1884988a9e5162a6b7a2b0d0cf8c83c5-300x300.png)