CA – IPC TEST MATERIAL COSTING MM: 34 Marks

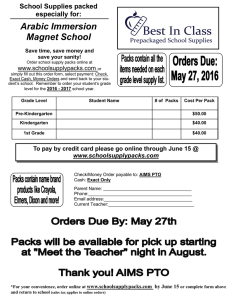

advertisement

CA – IPC TEST MATERIAL COSTING MM: 34 Marks Duration = 1 hour Solution 1: Difference between Minimum lead time Maximum lead time = 4 days Min. lead time = 4 days Or, Max. lead time = Min. lead time + 4 days . . . . . . . . . . . . . . . . . . . . . (i) Average lead time is given as 6 days i.e. Max. lead time + Min. lead time = 6 days . . . . . . . . . . . . . . . . . . . . . (ii) 2 Putting the value of (i) in (ii), Min. lead time + 4 days + Min. lead time = 6 days 2 Or, Min. lead time + 4 days + Min. lead time = 12 days Or, 2 Min. lead time = 8 days Or, Minimum lead time = 8 days = 4 days 2 Putting this Minimum lead time value in (i), we get Maximum lead time = 4 days + 4 days = 8 days (i) Maximum consumption per day: Re-order level = Max. Re-order period × Maximum Consumption per day 1,60,000 units = 8 days × Maximum Consumption per day Or, Maximum Consumption per day = 1,60,000 units = 20,000 units 8 days (ii) Minimum Consumption per day: Maximum Stock Level = Re-order level + Re-order Quantity – (Min. lead time × Min. Consumption per day) Or, 1,90,000 units = 1,60,000 units + 90,000 units – (4 days × Min. Consumption per day) Or, 4 days × Min. Consumption per day = 2,50,000 units – 1,90,000 units Or, Minimum Consumption per day = 60,000 units = 15,000 units 4 days Solution 2: Supplier Variable Cost Fixed Cost I 8 II 7.5 3,000 III 6.9 6,000 Cut off the order quantity between 1st and 2nd supplier = Fixed Cost per order/Per unit price difference = 3,000 / (8 – 7.50) = 6,000 units Cut off the order quantity between 2nd and 3rd supplier = (6,000 – 3,000) / (7.50 – 6.90) = 5,000 units Cut off the order quantity between 1st and 3rd supplier = 6,000 / (8 – 6.90) = 5,454.54 units From above calculations the conclusions are: (a) For order quantity below 5,454.54 units, the first supplier is economical. (b) For order quantity of 5,454.54 units, both 1st and 3rd suppliers are equally good. (c) For order quantity above 5,454.54 units 3rd supplier is better. Solution 3: Store Ledger of Aditya Ltd. (Weighted Average Method) Date Receipts Issues Balance of Stock Feb Qty (Kg.) Rate (`) Amount (`) Qty (Kg.) Rate (`) Amount (`) Qty (Kg.) Rate (`) Amount (`) 1 1,200 475.00 5,70,000 5 975 475.00 4,63,125 225 475.00 1,06,875 6 3,500 460.00 16,10,000 3,725 460.91 17,16,875 7 2,400 460.91 11,06,175 1,325 460.91 6,10,700 9 475 460.91 2,18,932 1,800 460.91 8,29,632 15 1,800 480.00 8,64,000 3,600 470.45 16,93,632 17 140 480.00 67,200 3,460 470.07 16,26,432 20 1,900 470.07 8,93,133 1,560 470.06 7,33,299 28 180* 470.06 84,611 1,380 470.06 6,48,688 *180 kgs. Is abnormal loss, hence it will be transferred to Costing Profit & Loss A/c Solution 4: Computation of Total Expected stock out cost Safety stock level (units) Stock out (units) (1) (2) 500 400 0 100 Stock out cost @ ` 40 per unit (`) (3) 0 4,000 Probability of stock out (4) 0 0.01 250 250 150 10,000 6,000 0.01 0.02 100 400 300 150 16,000 12,000 6,000 0.01 0.02 0.03 50 450 350 200 50 18,000 14,000 8,000 2,000 0.01 0.02 0.03 0.04 0 500 400 250 100 50 20,000 16,000 10,000 4,000 2,000 0.01 0.02 0.03 0.04 0.10 (A) Expected stock out at this level (`) [(3) x (4)] (5) 0 40 40 100 120 220 160 240 180 580 180 280 240 80 780 200 320 300 160 200 1,180 (B) Expected Annual Carrying Cost of SSL 10,000 10,000 8,000 8,040 5,000 5,220 2,000 2,580 1,000 1,780 0 The optimum safety stock is zero unit. Solution 5: (i) Calculation of Economic Order Quantity: EOQ = 2 x A x O = 2 x (60,000 packs x 12 months) x `240 = 3,893.3 packs or 3,893 packs C `228 x 10% (ii) Number of orders per year Annual requirements = 7,20,000 packs = 184.9 or 185 orders a year EOQ 3,893 packs (iii) Ordering and storage costs: 2 x A x O x C = 2 x 7,20,000 x `240 x `22.8 = `88,768 (iv) Timing of next order: Average delivery period = Maximum lead time + Minimum lead time 2 = 6 Days + 4 Days = 5 Days 2 Average usage per day = Annual Requirement 360 Days = 7,20,000 Packs = 2,000 Packs 360 Days Days requirement covered by Present inventory = Present Inventory Average usage per unit = 10,000 Packs = 5 Days 2000 Packs Timing for the next order = Average Delivery Period – Days Requirement covered by Present Inventory = 5 Days – 5 Days = 0 Days This means that next order for the replenishment of supplies has to be placed immediately. . (A) + (B) Total cost 1,180