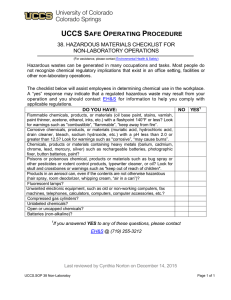

L S &

advertisement