EVANGEL UNIVERSITY CHEMICAL HYGIENE PLAN (CHP) 1

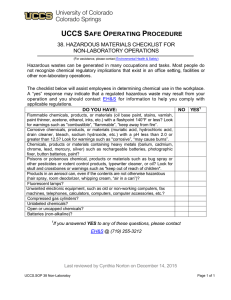

advertisement