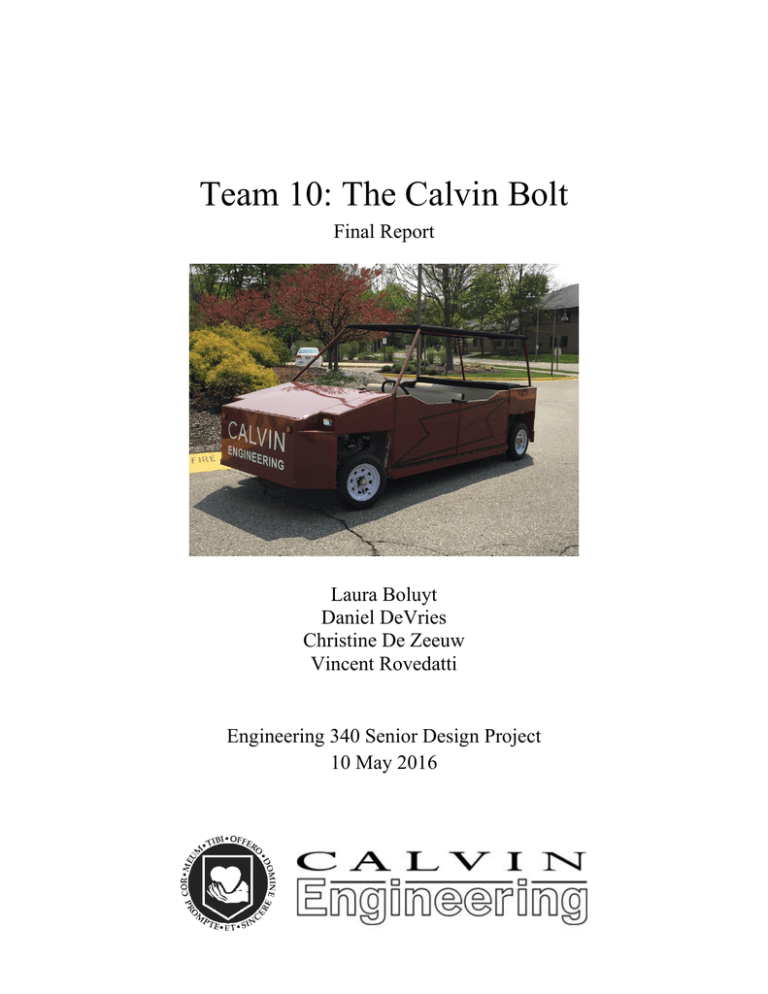

Team 10: The Calvin Bolt

advertisement