Modeling of Droplet Evaporation from a Nebulizer

advertisement

Modeling of Droplet Evaporation from a Nebulizer

in an Inductively Coupled Plasma

Craig M. Benson, Sergey F. Gimelshein, Deborah A. Levin and Akbar Montaser

The George Washington University

Washington, DC 20052 l

Abstract.

The evaporation rate of sample droplets in an inductively coupled plasma is investigated through the

development of two models using the direct simulation Monte Carlo technique. A standard continuum

evaporation model is contrasted with a kinetic technique designed to obtain correct results over a large

range of Knudsen numbers. The droplet evaporation rates predicted by the continuum desolvation model

are found to be in agreement with those of previous studies. We present the first predicted spatial distribution

of droplet concentrations and evaporation rates in an ICP flow.

INTRODUCTION

Atmospheric pressure argon inductively coupled plasmas (ICPs) are electrical discharges that have dramatically altered the practice of elemental and isotopic ratio analysis. [1,2] An analyte is most commonly introduced

into an ICP for mass spectrometric, atomic emission, or atomic fluorescence analysis via a spray of dilute aqueous solution. Numerical modeling can assist in predicting the fate of sample droplets, which will lead to a

better understanding of the amount of detectable analyte in the nebulizer spray. To this end, a two-phase flow

computational model has been developed to predict the desolvation rate of droplets in the plasma. [3]

Analytical measurements of the droplet desolvation rate within the ICP are very limited due to experimental

difficulties. Recent work addressed the issue of droplet desolvation in an ICP [4]. The effect of a specific

distribution of particle sizes and velocities was not considered; thus, the model could not predict the behavior

of the spray as a whole. In addition, our approach provides a more detailed description of the change in droplet

velocities due to interactions with argon in the plasma and the two-dimensional size distribution of particles

in the ICP.

The nebulizer chosen for this study is the direct injection high efficiency nebulizer (DIHEN)[5-7], a concentric

micronebulizer for applications in which the sample is limited, expensive, or toxic. A fast flow of argon gas

causes the liquid sample to disperse into droplets ranging from 0.5 to 25 /xm in size with an average velocity

of 12.4 m/s. These droplets are then injected directly into the base of the plasma.

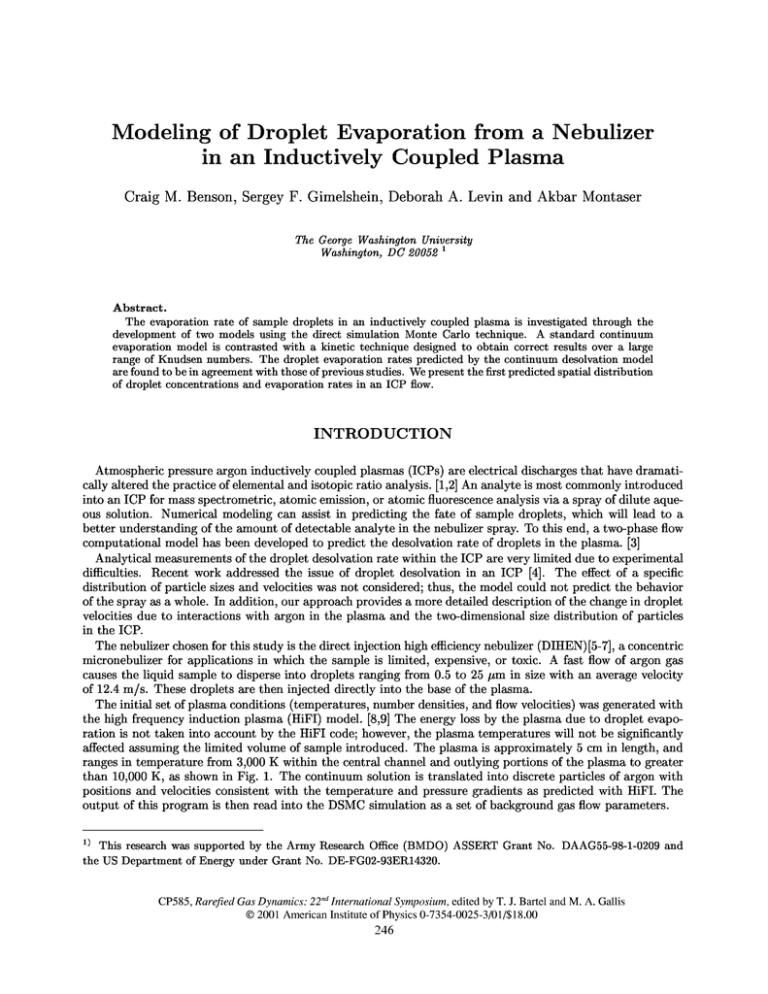

The initial set of plasma conditions (temperatures, number densities, and flow velocities) was generated with

the high frequency induction plasma (HiFI) model. [8,9] The energy loss by the plasma due to droplet evaporation is not taken into account by the HiFI code; however, the plasma temperatures will not be significantly

affected assuming the limited volume of sample introduced. The plasma is approximately 5 cm in length, and

ranges in temperature from 3,000 K within the central channel and outlying portions of the plasma to greater

than 10,000 K, as shown in Fig. 1. The continuum solution is translated into discrete particles of argon with

positions and velocities consistent with the temperature and pressure gradients as predicted with HiFI. The

output of this program is then read into the DSMC simulation as a set of background gas flow parameters.

^ This research was supported by the Army Research Office (BMDO) ASSERT Grant No. DAAG55-98-1-0209 and

the US Department of Energy under Grant No. DE-FG02-93ER14320.

CP585, Rarefied Gas Dynamics: 22nd International Symposium, edited by T. J. Bartel and M. A. Gallis

© 2001 American Institute of Physics 0-7354-0025-3/01/$18.00

246

ICP Temperatures,

Temperatures, K

K

ICP

11

3524

=3524=

6063

-6063-

0.8

0.8

0.6

0.6

8 602

0.4

0.4

0.2

0.2

9871

00 0

0.2

0.2

0.1

0.1

2

3

4

)// 1/ ( v

•

4793

Position, cm

0.4

0.4

0.3

0.3

1

73

*^|

i^

5

^

9871

\

""""~— —————— — ————.......—...—......-.. — — — -QO'74 ..

32

1 8\ %

^-^

.......„....——-———""""'

8602

1 v ^^^•~——:::^^

0

°C0)

11

22

33

Position, cm

cm

Position,

r

Î

I

»

Ï

¤

"

ª

¡

£

¢

¤

0

¯

¢

È

´

£

¢

=

2

¬

¦

¥

l

§

¤

N

©

P

b

©

0

¢

³

2

¬

¦

¥

°

¤

¬

E

µ

²

¥

¤

U

¤

2

È¥ QÎÍ° {¬2P¾¶I2L«¦ ³µI¢N° P§{¤ P¯2¢©b©r2 ¼µº¤2L¡ P¢r¤¥¦ P§; P¨f¤

FIGURE

plasma

2«­P©rª®included

¥¦§°«­1.¯¬2³ICP

¬in¥¦§Utemperature

¤the DSMC

¹/»`simulation

©rgradients

¥¦ª®¯2«Ì¼¤¥¦ =§/asdomain.

¬0 =predicted

ªP¥¦§É¾ with the HiFI code. The lower contours show the portion of the

c2d?eGfKg:hji

^k

_

MJMN

× 6Ù

ÀÔÖÕ Ù

Òe× ÒeØ (ÔÖÑ¡Ù Ù

Ò

ðyÜisä}ß"well

ÿÈâíæí known

êÚÞlÿcê`that

ÜáfèlÜthe

ÜáÚâ DSMC

Àñ ÝÅâ¼ÜáÉÞëisä}ßaè(reliable

ãâíæä}è íæâÂand

è{êÉë`efficient

â /åäÌâPêÜ kinetic

äÌêÚâÜä}åÂapproach

è{àÉàÚãÞè0åáÀfor

õuÞ0ãÝÅÞ¡ë¡âPíÌäæêÚérarefied

ãè{ãâ Éâ=ë

égas

2è0Itß-flows.

üÉÞlÿ-ßPöO[10]

÷Ìø lû During

ÆçÉãäæêÚéÂthe

ÜáÚâpast

àfè0ߣܸseveral

ߣâPì0âPãmethod

è0íjyears,

î0â=è{ãßùfitä­Ü8has

áÉè0߸also

è{í}ß£Þ been

âPâêsuccessfully

ßçÉååâPßßõuçÉíÌíæî·applied

è0àÚàÚíæäÌâ=ë(toÜÞmodeling

ÝÅÞëÚâíæäÌmodeling

êÚéofÞ{õbflows

üÉÞlÿ-ßÆinäÌêWthe

ÜáÚâ

ênear-continuum

ÚâPè0ã£ôrå¼Þ2ê2ÜäÌêçÚçÉÝ regime.

ãâPé0äæÝ;â2ö The

LáÚâ/numerical

êçÚÝÅâPãä}åè0íIscope

ßå¼Þ2àfâÅinäæêthis

ÜáÚä}ß"work,

ÿ^Þ2ã Qù#however,

áÚÞlÿÈâì2âã=ùQisäæß"quite

ýçÚäÌÜâ/different

ë¡ä ?âPãâPêÜ"from

õuãÞ2Ý the

ÜáÚâÂconventional

åÞ0êì0âPê2ÜäÌÞ2êÉè{í

è{àÚàÚíæä}åèlÜäÌÞ2êWareas

è{ãâPè2ßcÞ{õbÜáÚâ DSMC

ÀñeÝÅâÜáÚÞ¡ë#ö¸Inðrêthis

ÜáÚä}ß®approach,

è{àÚàÚãÞ2è2åájùÚthe

ÜáÚâ DSMC

Àñmethod

Ý;âÜáÚÞ¡ëisä}߸utilized

ç¡ÜäæíÌä â=ëinäæêWthe

ÜáÉâUßäÌÝUçÚíæè{ÜäæÞ0êofÞ0õ

application

ëdroplet

¡ãÞ2àÚíæâ¼Ü-evaporation

âìlè0àfÞ2ãè{ÜäæÞ0ofê·inthe

äÌêWaè/continuum

åÞ0êÜäæêçÚmethod.

çÚÝ regime.

ãâé2äÌÝÅâ2ö The

LáÚâselection

ßâíæâPå¼ÜäæÞ0ê(ofÞ{õ¶the

ÜáÉâ DSMC

ÀñTmethod

Ý;âÜáÚÞ¡ë·forõuÞ2ãcthis

ÜáÚä}ßÆapplication

è0àÚàÚíæäæåPèlsimulation

ÜäÌÞ2ê·ä}ß-ë¡çÉâ"toÜÞ

Üthe

áÚâ"fact

õè2å³Ü¸that

ÜáÉè{ܸdroplets

ë¡ãÞ0àÚíæâ¼Üßcexhibit

â ¡áÚä äÌܸparticle,

àÉè0ã£ÜäæåíÌâ2ùÉorÞ0ãÆmicroscopic,

Ý;ä}å¼ãÞ2ßå¼Þ2àÚä}å{ù behavior

âáÉèìäæÞ0ãcthat

ÜáÉèlÜ®can

åè{ê beâmore

ÝÅÞ2ãâ"reliably

ãâíæäæè íæî+investigated

äæêì2âPߣÜäæé2è{ÜâPisë·due

ÿcäÌÜáWaè

kinetic

äæêÚâÜä}å¸approach.

è0àÚàÚãÞ2è0åáÍö Since

äæêÉåâÆthe

ÜáÚâ DSMC

`ñÖmethod

ÝÅâ¼ÜáÚÞ¡ë+isä}ß^theÜáÚâ8most

ÝÅÞ2ߣÜÈpromising

àÉãÞ2Ý;ä}ßäÌêÚé kinetic

äÌêÚâÜä}å¸approach

è0àÚàÚãÞ2è2åáÂinäÌê+terms

ÜâPãÝ/ßÈofÞ{õIdifferent

ë¡ä QâãâêÜLwith

ÝÅÞëÚâí

äimplementations

ÌÝÅàÚíæâÝÅâêÜèlÜäæÞ0êfßUand

è0êÉëmodeling

ÝÅÞ¡ë¡âíæäæêÚéofÞ0õ-two-and

Üÿ^Þ0ôyè0êÉë`three-dimensional

ÜáÉãâPâ¼ôrë¡äÌÝÅâPêÉߣäæÞ0êfè{í^flows,

üÉÞlÿ-ßùbitäÌÜÅisäæßUused

çÉßâPëinäæêthis

ÜáÚä}ßUwork

ÿÈÞ0ã ÀtoÜÞstudy

ßÜçÉë¡îºdroplet

ë¡model

ãÞ0àÚíæâ¼Ü

âevaporation

ìlè{à?Þ0ãèlÜäÌÞ2ê+inäæê(aè;plasma.

àÚí}è0ßÝ/èÚö

LáÚâPãâ·are

è{ãâ+several

ßâì0âPãè0íNàÚáÉâêÚÞ2Ý;âPêÉèWinäæêthis

ÜáÚä}ßflow

üÉÞlÿ ÜáÉèlÜÅhave

áÉèì2â Þ0Üá!interesting

äÌêÜâPãâ=ßÜäÌêÉénumerical

êçÚÝÅâãäæåPè{íÈand

è{êÉëºphysical

àÉáî¡ßäæåPè{íLsignificance.

ߣäæé0êÉä fåPè{êÉåâ0ö

LTheáÚThere

â-flow

üÉÞlÿ ofÞ0õÍinterest

äæê2ÜâãâPߣÜ^isä}phenomena

ß^aètwo-phase

Üÿ^Þ0ôAàÉáÉè0ßâcflow.

üÉÞlÿ"ö There

LáÚâPãthat

âÆare

è0ãâ¸liquid

íÌä}ýçÚä}ë+both

ëdroplets

¡ãÞ0àÚíæâ¼ÜßEthat

ÜáÉèlÜÈmay

Ý/èî;evaporate,

âPìlè{à?Þ0ãèlÜâ2ùcoalesce,

åÞ2è0íÌâ=ßåâ0ù2and

è0êÉë+condense,

åÞ0êÉëÚâêÉßâ0ù

Ýmoving

;ÞlìäæêÚéwithin

ÿcäÌÜáÉäÌê(aègas.

éè0ßPö This

LáÚä}ßLaspect

è0ßàfâ=å³ÜLraises

ãè0äæßâPß^many

Ý/è{êî;theoretical

ÜáÚâPÞ0ãâ¼ÜäæåPè{íQand

è{êÉë+practical

àÚãè2å³ÜäæåPè{íQquestions

ý2çÉâPߣÜäæÞ0êÉßÈconnected

å¼Þ2êÚêÚâPå¼Üâ=ëÂwith

ÿcäÌÜáÂthe

ÜáÚâ8necessity

êÚâPåâPßߣäÌÜî

Þof{õEanè{êWadequate

è2ë¡âPýçÉè{Üâdescription

ë¡â=ßåãäæà¡ÜäæÞ0êofÞ0õEdroplet

ë¡ãÞ2àÚíæâ¼ÜÆcondensation/evaporation

å¼Þ2êÉë¡âPêÉßè{ÜäæÞ0ê lâìlè{à?Þ0ãèlÜäÌÞ2êand

è0êÉë(interactions.

äÌêÜâãè0å³ÜäÌÞ2êÉßPö Different

¸ä Qâãâêܸflow

üÉÞlÿhregimes

ãâé2äÌÝÅâ=ßcexist

â ¡ä}ßÜ

õforuÞ0ã-the

ÜáÚâdroplets

ë¡ãÞ0àÉíÌâÜßÆand

è0êÉë(gas.

é2è2ßö While

áÚäæíÌâ;droplets

ë¡ãÞ0àÚíæâ¼ÜßÆareè{ãâ"inäæê(theÜáÚâtransitional

Üãè{êÉßä­ÜäÌÞ2êÉè{íÍorÞ0ã-even

âPì0âê(free

õuãââmolecular

Ý;Þ2íÌâ=å¼çÚí}è{ãÆregime

ãâPé0äæÝ;âwith

ÿcä­Üárespect

ãâ=ߣà?âPå¼Ü-toÜÞ

âPè0åáÅother,

Þ0ÜáÚâPãPù0the

ÜáÚâ-ßçÚããÞ2çÚêÉë¡äæêÚé"gas

é2è2ßIisäæßNaècontinuum.

å¼Þ2ê2ÜäÌêçÚçÉÝ·ö Finally,

¶äÌêfè{íæíÌî2ù{the

ÜáÉâÆߣçÉããÞ0çÚêfë¡äÌêÉé®gas

éè0ßbisä}ßEatè{ÜNhigh

áÚäæé0á;ÜâPÝ;à?âãèlÜçÚãâPßPù0while

ÿcáÚäæíÌâ-ÜáÚâ

each

ëdroplet

¡ãÞ2àÚíæâ¼Üsurface

ߣçÉã£õè2å¼â;surrounding

Ütemperature

âPÝ;à?âãèlÜçÚãâ;isä}ß"relatively

ãâí}èlÜäÌì2âíæîWcool.

å¼ÞÞ0íAö This

LáÚä}ß8indicates

äÌêÉëÚäæåPèlÜsurrounding

â=ß8that

ÜáfèlÜmodels

ÝÅÞ¡ë¡âí}ß"developed

ë¡âì2âíæÞ0à?âPëtemperatures,

ÜtoÞWdescribe

ë¡â=ßåãä âÅdroplet/gas

ëÚãÞ2àÚíÌâÜ lthe

é2è0ß

äinteractions,

ÌêÜâPãè2å³ÜäÌÞ2êÉßù{assuming

è2ßßçÚÝÅäæêÚé®aè8small

ßÝ/è{íæídifference

ëÚä QâãâêÉåâLinäÌêÅdroplet

ë¡ãÞ0àÚíæâ¼ÜEsurface

ßçÚã£õè2å¼âLand

è{êÉëUgas

é2è2ßOtemperatures,

ÜâÝÅà?âãèlÜçÚãâ=ßù{are

è0ãâÈnot

êÚÞ0ÜIlikely

íæä 0âíæî8toÜÞ beâ-applicable

è{àÚàÉíÌä}åè íÌâ

õuÞ0ã®this

ÜáÚä}ß8case.

åè2ߣâ2öAsÛÆß8aèpreliminary

àÚãâPíÌäæÝÅäÌêfè{ãî·effort,

â ?Þ2ã£Ü=ùQthis

ÜáÚä}ß8ÿÈÞ0ã ·examines

â Úè{ÝÅäÌêÉâPß®droplet

ë¡ãÞ2àÚíæâ¼Ü8âìlè{à?Þ0ãèlÜäÌÞ2êcaused

åè0çÉߣâ=ë îWèáÚäÌé2á¡ôAÜâÝÅà?âãèlÜçÚãâ

for

èargon

{ãé0Þ0êgas

é2è2ß^using

çfߣäæêÚé/aè DSMC

Àñscheme

ßåáÚâPÝ;â8modified

ÝÅÞ¡ë¡ä ÉâPëtoÜwork

Þ/include

äæêÉåíÌçÉëÚâdroplet-argon

ë¡ãÞ2àÚíæâ¼Ü£ôrè{ãé0Þ2êÂevaporation

äinteractions.

æê2Üâãè0å¼ÜäæÞ0êÉßPö by a high-temperature

LáÚâ"ߣÜè{Üä}ßÜäæåPè{íQmodeling

ÝÅÞëÚâíæäÌêÚéÅinäæêlow-density

íæÞlÿLôrë¡âêÉßäÌÜî;environments

âPêìäæãÞ0êÚÝÅâêÜß®(SMILE)

ï ð ^óÈcomputational

å¼Þ2Ý;àÉç¡Üè{ÜäæÞ0êÉè0íftool

ÜÞÞ0íb[11]

÷­ø2ø¼û based

è2ߣâ=ë+Þ2êÂÜáÉâ DSMC

Àñ

Ýmethod

;The

âÜáÚÞ¡ëstatistical

äis}ß"used

çÉßâPë`inäæêthe

ÜáÚâÂcomputations.

åÞ0ÝÅàÚç¡ÜèlÜäæÞ0êfßö The

LáÚâ SMILE

ð etool

ÜÞÞ0íEisä}ß"extended

â ÜâêÉëÚâPë`toÜÞWsimulate

ßäæÝçÚí}èlÜâÂdroplet

ë¡ãÞ2àÚíæâ¼Ü behavior

âáÉèìäæonÞ0ã"inthe

äæêÀtheÜáÚâ+conåÞ0ê¡ô

ÜäæêçÉçÚÝ regime.

ãâPé0äæÝ;â2ö Several

âì2âãè{íEäæÝÅàfÞ2ã£Üè{êÜfeatures

õuâPè{ÜçÚãâPßofÞ{õcthe

ÜáÚâ+å¼Þ¡ë¡âenable

âêÉè íæâÂusçÉß"toÜÞWimprove

äæÝ;àÉãÞlì2âÅtheÜáÚâ·accuracy

è0ååçÚãè0å¼î`and

è{êÉëâ Âå¼äæâêÉåîÀofÞ0õ

tinuum

Üthe

áÚâÂsimulation,

ßäÌÝUçÚí}èlÜäæÞ0êÍùÍsuch

ߣçfåá`asè2ß®anè0important

êºaccurate

è0ååçÚãèlÜâÅcollision

å¼Þ2íÌíæä}ߣäæÞ0ê`scheme

ßåáÚâPÝÅcode

â([12],

÷Ìø=úlûAùOspecies

ߣà?âPåäÌâ=ß"and

è{êÉë`spatial

ߣàfèlÜä}è{íbweights,

ÿÈâäæé0áÜßùÍand

è0êÉë`different

ë¡ä Qâãefficiency

âêÜ"grids

é0ãä}ëÚß®forõuÞ0ã

åcollisions

¼Þ0íæíæäæßäÌÞ2êÉßLand

è{êÉë·macroparameters,

Ý/è0åãÞ2àÉè{ãè{ÝÅâÜâãßPù0each

âPè2åá·adaptive

è2ëÚè{àÚÜäæì0â®toÜÞ;flow

üÉÞlÿhgradients.

é0ãè0ë¡äæâêÜßPö

LáÚâÅâPìè0àfÞ2ãè{ÜäæÞ0êÀprocess

àÚãÞ¡åâPß߸has

áfè0ß been

âPâêÝÅÞ¡ë¡âíæâPë`asè0ß®follows.

õuÞ2íÌíæÞlÿ-ßö The

LáÚâÅðñÈòeisäæß8maintained

Ý/è{äæêÜè0äÌêÚâ=ëatè{Ü"aè(steady

ߣÜâ=è0ë¡îstate,

ߣÜè{Üâ2ùÍand

è{êÉëÀäÌÜ8ä}ß

ãreasonable

â=The

è0ßÞ0êÉè evaporation

íÌâ-toÜÞ/assume

è0ßߣçÉÝ;âÆthat

ÜáÉè{ÜLthe

ÜáÚâ8plasma

àÚí}è0ßÝ/èmodeled

àproperties

ÚãÞ0à?âãÜäæâPßÈare

è{ãâ®not

êÚÞ{Ücaffected

è QâPå¼ÜâPICP

ëwith

ÿcäÌÜáthe

ÜáÚâ®introduction

äÌêÜãÞ¡ë¡çÉå¼ÜäæÞ0ê·ofÞ{õOaèUlimited

íæäÌÝÅäÌÜâPë·amount

è{ÝÅÞ2çÚêitÜÈofisÞ0õ

ßè0Ý;àÉíÌâ2ö -âPêÉå¼â2ùlthe

ÜáÉâÈè0ãé2Þ0ê"plasma

àÚí}è0ßÝ/è-isä}ßOmodeled

ÝÅÞ¡ë¡âPíÌâ=ëè0߶aè background

è0å é0ãÞ0çÉêÉë"argon

è{ãé0Þ2ê"gas

é2è0ßOáÉèìäæêÚéÆallè{íæíthe

ÜáÚâÈÝ/è0åãÞ2àÚãÞ2àfâPã£ÜäÌâ=ßN(density,

ïYë¡âêÉßäÌÜî0ù

sample.

ìvelocity,

0âíæÞ¡å¼äÌÜî0ùQHence,

èand

{êÉë·temperature),

ÜâÝÅà?âargon

ãèlÜçÉãâó³ùQofÞ{õbthe

ÜáÚâUcalculated

åPè{í}å¼çÚí}èlÜâPë(asplasma.

àÚí}è0ßÝ/èÚö Using

¸ß£äæêÚéaè background

è0å é0ãÞ0having

çÉêÉë·gas

é2è0ßÆimplies

äÌÝÅàÚíæäæmacroproperties

âPß®certain

å¼âãÜè0äÌêWsimplifications.

ßäæÝ;àÉíÌä fåè{ÜäæÞ0êÉßPö

Û-ãé0Þ0ê·atoms

èlÜÞ0Ý/ßLare

è{ãâ¸ßè{ÝÅàÚíæâPëonce

Þ0êÉåâ¸àÚãäæÞ0ãÈtoÜÞUthe

ÜáÚâ8Ý/è{äæê(simulation

ߣäæÝçÚí}èlÜäÌÞ2ê+using

çÉßäæêÚéUequilibrium

â=ýçÚäÌíæä ãäæçÚÝ ëÚäæߣÜãä ç¡ÜäæÞ0êÉßLwith

ÿcäÌÜáthe

ÜáÉâ®locationíæÞ¡åè{ÜäæÞ0ê¡ô

Argon

ëdependent

¡âà?âêÉëÚâêÜparameters

àÉè{ãè{ÝÅsampled

âÜâãß®obtained

Þ Üè{äæêÚâPëprior

õfrom

uãÞ0Ý HiFI.

Æä ¶ð³ö main

¸Using

ߣäæêÚé(equilibrium

âPýçÚäæíÌä ãäÌçÉÝdistributions

ë¡ä}ßÜãä ç¡ÜäÌÞ2êÉß8isä}ß8distributions

ãreasonable

â=è0ßÞ0êÉè íÌâÅsince

ßäÌêÉåâ;the

ÜáÚâ/plasma

àÚí}è0ßÝ/è+isä}ß

äÌêthe

ÜáÚâÅcontinuum

å¼Þ0êÜäÌêçÚçÚÝ regime.

ãâé2äÌÝÅâ0ö These

LáÚâPßâUargon

è0ãé2Þ0êatoms

èlÜÞ0Ý/ßÆare

è0ãâthen

ÜáÚâPê fixed

¡âPëWäÌêÜáÚâ DSMC

`ñߣäæÝçÉíæè{ÜäæÞ0êÉß®such

ߣçfåá(that

ÜáÉè{ܸthey

ÜáÚâîdoë¡Þnot

êÚÞ{Ü

in

Ýmove

;Þlì2â+over

Þlì2âãUtime

ÜäæÝ;âand

è0êÉëdoë¡Þnot

êÚÞ0ÜÅcollide

åÞ0íæíÌä}ë¡â·with

ÿcä­Üá!each

â=è0åá!other.

Þ{ÜáÉâã=ö Therefore,

LáÚâãâ¼inõuÞ2ãthe

â2ùbthe

ÜáÉâ·properties

àÉãÞ2àfsimulations

âPã£ÜäÌâ=ßpredicted

àÚãâPëÚäæå¼ÜâPë!with

ÿcäÌÜá HiFI

-ä OðUremain

ãâPÝ/è{äæê

å¼Þ0êfßÜè{êܸthroughout

ÜáÚãÞ0çÚé2áÚÞ0ç¡Ü®the

ÜáÉâÅsimulation.

ßäæÝçÚí}èlÜäÌÞ2êjö;Argon-argon

ÛÆãé2Þ0ê¡ôrè{ãé0Þ2êcollisions

å¼Þ0íæíæäæßäÌÞ2êÉß8are

è{ãâUêÉÞ{Ü"modeled,

ÝÅÞëÚâíæâPë#ùÍè0êÉëthe

ÜáÚâÅà?Þ2ßä­ÜäÌÞ2êÉß8ofÞ{õ^the

ÜáÚâ/argon

è{ãé0Þ2ê

constant

èatoms

lÜÞ2Ý/ß"doë¡Þnot

êÉÞ{Üchange,

åáÉè0êÚé0â2ùQthus

ÜáçÉß8preserving

àÚãâPßâãìäÌêÚéthe

ÜáÉâ/number

êçÉÝ âãdensities

ë¡âPêÉߣäÌÜäæâPß"and

è0êÉënot

Ütemperatures

âÝÅà?âãèlÜçÚãâ=ß"and

åcalculated

è0íæåçÚíæè{Üpositions

â=ëWwith

ÿcäÌÜá HiFI.

-ä ¶ð³öÍNo

þ-Þ(new

êÚâPÿ

ml^n

poqrq

so

stuo

vnxw

9ozy

stjozy0y0w

|{zw}l

DSMC APPROACH AND NUMERICAL CHALLENGES

~

;>=

0

6!

G

G;>=

G;>=

E

0<;=

;

<;>=

G

)

'

O

O

,

(

'

<;=

;>=

;>=

;>=

7;

K

*

?

<

,

?

/

C

K<;>=

247

1,

1,

argon is introduced or removed from the simulation domain. Such an approach circumvents any potential

computational difficulties connected with calculating argon collisions at atmospheric pressure.

The number of collisions calculated in a standard fashion is directly proportional to the total collision crosssections of the particles in the gas and species number densities. The droplets generated by the DIHEN

range from approximately 0.5 pm to 25 p,m in diameter; therefore, the collision cross section of each droplet

is correspondingly larger than a gas particle cross section. Since there is a high argon number density, one

may conclude that to model each argon-droplet collision would be prohibitively large. To effectively model

the collision process for droplets, a special procedure is implemented to reduce the number of droplet-argon

collisions by a factor of approximately IxlO10, but also increase the energy transfer during each collision by

the same factor. This allows an equivalent amount of energy to be transferred during a single timestep, thus

preserving both the calculation of droplet evaporation rate and the change in velocity of the droplets, while at

the same time reducing the number of collisions calculated for each droplet.

The flow in the DIHEN is assumed to have an axial symmetry, and an axisymmetric SMILE code has

therefore been used. To examine droplet evaporation in more detail, only a portion of the ICP was modeled

adjacent to the nebulizer nozzle. The radius enclosed by the simulation is 4.0 mm from the center of the

plasma, and extends 3.0 cm within the plasma. Although HiFI predicts temperatures and number densities

for a plasma approximately 5 cm long with a 1 cm radius, all droplet evaporation occurs within the smaller

computational domain, and thus any extension of the simulation domain beyond that point is unnecessary.

The grid is uniform and consists of 40 cells in the y direction and 120 cells in the x direction. The time step

is IxlO"6 s. The number of background argon molecules is about one million.

DISCUSSION OF EVAPORATION MODELS

Two droplet desolvation models are used to simulation particle evaporation and the effect of gas/droplet

collisions on droplet temperature and diameters. The first one, a standard model for droplet evaporation, is

widely used, especially in combustion applications [13-15]. Since a continuum regime is assumed, the model

may not work properly in the limit of high Knudsen number. The second model uses a kinetic approach

which yields equally accurate results for all Knudsen numbers [19,20]. The key assumption is that the droplet

evaporation rate can be calculated by assuming small temperature and pressure changes from droplet /gas

equilibria.

The continuum evaporation model is described as follows. The mass flux of water from the surface of a

droplet is governed by the following equation [13]:

mv = 2nD -

In(l + BM)

(1)

where mv is the mass flux of water from the surface of the droplet, D is the diameter for the droplet, k is the

thermal conductivity and cp the heat capacity of the gas surrounding the droplet, and BM is the mass transfer

constant, based upon the mass fraction of water vapor at the droplet surface.

The droplet surface temperature is initially 298 K, and then increases as the droplet remains in the plasma.

The rate of increase is dependent upon the amount of energy absorbed by the droplet over the course of a single

timestep. The amount of energy absorbed is dependent in turn on the energy gained by the droplet through

droplet-argon collisions and the energy lost to the surroundings via evaporation processes.

At some point, the evaporation rate of the droplet will become sufficiently high such that the net energy

gain by the droplet during a single timestep approaches zero. At this point, no further energy is available to

heat the droplet, and it will therefore reach a quasi-steady temperature. This representative temperature is

known as the wet-bulb temperature of the droplet.

The above analysis yields a droplet evaporation model consistent with the D2 law [13], which states that

a plot of the square of an evaporating droplet's diameter versus time will be linear, with the slope equal to

the evaporation constant for the droplet. For a droplet with a 10-/xm initial diameter in a uniform 3,000 K

environment, the above analysis indicates a wet-bulb temperature around 365 K, a droplet heating time of

approximately 0.03 ms, and a total droplet evaporation time of 0.21 ms.

The limitations of the standard evaporation model are the assumption of a continuum regime and the

requirement of a unitary Lewis number. The Lewis number is the ratio of thermal and mass diffusivities in

the droplet; a value of 1 indicates that the energy and mass transport via diffusion are equally effective in the

248

boundary layer surrounding the droplet. This is not necessarily the case for every system. The Young-Carey

model [18-20], a kinetic approach, does not share these two limitations.

Young [19,20] has proposed a general model to describe droplet evaporation occurring under nonequilibrium

conditions:

The factors &pv/pv,oo and AT/T^ represent the deviations from equilibrium associated with variations

in pressure and temperature. Young derives the phenomenological coefficients, Lmm and Lmq, by analyzing

the relative pressure and temperature jumps found at the droplet-continuum interfaces. A full analysis can

be found in Young's work [19,20]; however, it is worth noting here that the primary differences between the

Young-Carey model and the continuum model lies in the dependencies of the phenomenological coefficients on

Sc, the Schmidt number; Pr, the Prandtl number; and Kn, the Knudsen number.

The gas-droplet surface Knudsen number is defined with the characteristic length taken to be the diameter

of the evaporating droplet, as Kn = A/D, and A is the gas mean free path. The use of a Knudsen number

dependent on D causes Lmm and Lmq to be proportional to D. Thus the evaporation rate is found to have a

linear dependence of D2 with time, which brings the kinetic approach into agreement with the continuum D2

law.

RESULTS

Although the results of primary interest are the final points of evaporation for droplets generated by a DIHEN

in an ICP, the simulation can also yield valuable information in combustion and atmospheric condensation

problems. The DSMC /evaporation model is therefore tested under a variety of conditions, as described in

Table 1.

TABLE 1. Initial conditions for simulations2

Case

1

2

3

4

5

6

7

Temperature

2000 K

ICP

2000 K

ICP

ICP

2000 K

ICP

2

Droplet Distribution

10-pm

10-pm

DIHEN

DIHEN

DIHEN

DIHEN

DIHEN

Model

Continuum evaporation

Continuum evaporation

Continuum evaporation

Continuum evaporation

Continuum (with recondensation)

Kinetic evaporation (Young-Carey)

Kinetic evaporation (Young-Carey)

Figure

2

3

4

5

All simulations use the DIHEN droplet velocity distribution.

The simplest of the cases considered consists of a uniform background gas at a temperature of 2,000 K with

no net gas flow or macroscopic pressure gradients and an initial droplet diameter of 10 jum. This case will

help to illustrate the trends in droplet evaporation due to the initial particle velocity distribution. Figure 2

shows the results of the simulation. Although a small number of droplets can reach distances of 8 mm from

the nebulizer tip due to their higher velocities relative to the other droplets in the plasma, 90 percent of the

droplets are completely desolvated within 4 mm. On average, a droplet will travel 2.5 mm, representing a

residence time in the simulation domain of 0.20 ms.

Now consider simulation 2 (Table 1) with a constant droplet distribution but with a background gas consistent

with an ICP. The pressure is close to atmospheric conditions; however, the temperature is much higher than

2,000 K. In addition, there is a large background gas flow in the positive x direction due to the 300 m/s nozzle

exit velocity of the nebulizing gas (this high velocity is achieved due to the small DIHEN gas exit annulus,

despite the relatively low volume flow of gas). The background flow increases the axial velocity of the droplets,

leading to the result that some droplets survive to approximately 1.1 cm from the nozzle, more than 25 percent

249

Droplet

Droplet Number

Number Density

Density

11

0.8

0.8

6.9

0.6

0.6

4.1

6E

1.39

+1

1

E+1

1

1.25E+12

0.4

0.4

4E

+1

1

0.2

0.2

0.8

0.8

1

6

0.6

°'

•D

CO

tt

0.4

0-4

04

E+

I

5E

+0

4

E+ 0 5

£

8.9

98

2.

E

2.09

Radial Position, mm

Droplet

Droplet Evaporation Rate

0.2

0.2

1

¥¦§/¸¯§¥²¨æ P¢ª

c2d?eGfKg:hvØ

2

3

È¢ =2«­¤O§{¯2ª®Ã¡¢Q¬2§2©r¥¦¤Y±-¥¦§8ª OP§¬ÆPP¡ P¢£¼¤¥¦ =§®¢£¼¤b¥­§¸ª ¶© I¨æ P¢O fª ¯2§¥²¨} ¢ª¬0¢ P«¦¤Í¬2¥¦©y¤r¢¥¦Ã¯0¤¥¦ =§

8Ä ÃP°£Á0´¢ =¯2§¬U´=P©¾

J

Axial Position,

Position, mm

Axial

&Ù>Ú

&Ù>Ú

?Ù/Z

Z[VIÒ

FIGURE 2. Droplet number density in m~3 and evaporation rate in m~3 s~l for a 10-pm uniform droplet distribution

Û\6[6[Y[

in a uniform 2000 K background gas.

õè{ãÜáÚâPãIÜáÉè0êÜáÚâ-ë¡ãÞ0àÚíæâ¼ÜßIäÌê;ÜáÉâcíÌÞlÿÈâã¶ÜâPÝÅàfâPãè{ÜçÚãâ0ù{çÉêÚä­õuÞ2ãÝ é2è0ßPöOÛÆêîäæêÉå¼ãâPè2ߣâÈäÌêÅâPìè0àfÞ2ãè{ÜäæÞ0êUãè{Üâcë¡çÚâÈÜÞ"áÉäÌé2áÚâã

ÜâÝÅà?âãèlÜçÚãâ=ßcíæâPè0ëÉßcÜÞÂè+ߣáÚÞ2ã£ÜâãcãâPßäæëÚâêÉåâ"ÜäæÝÅâÞ{õIÜáÉâë¡ãÞ0àÚíæâ¼ÜÆäæê(ÜáÉâàÚí}è0ßÝÅè ÉáÚÞlÿÈâì2âã=ùÜáÚä}ß-ä}ß-ÝÅÞ2ãâ8ÜáÉè{êÞ Qßâ¼Ü

î·ÜáÚâ;è2ååâíæâãèlÜäæÞ0êàÉãÞlìä}ë¡âPë î·ÜáÉâUêÚâ çÚíæä Pâã8é2è2ßö LáÚâÅèì0âãè{é2âë¡ãÞ0àÚíæâ¼Ü®ÿcäÌíæíIàfâPêÚâ¼Üãè{ÜâÜáÚâ;àÚíæè2ߣÝ/èÂÜÞ`ø0ö /ÝÅÝ

ïuäæêÉë¡ä}åèlÜäÌêÉéÂè{êèì0âPãè0é0âÆãâPßä}ë¡âêÉåâ8ÜäæÝÅâ"Þ{õ Úöæø=úUÝ/ßù ;àfâPãåâêÜÆߣáÉÞ0ãÜâãLÜáÉè{ê(äæê(ÜáÚâ"íæÞlÿhÜâÝÅà?âãèlÜçÚãâ"ßäÌÝUçÚí}èlÜäæÞ0ê?ó³ù

ÿcáÚäÌíæâ Uà?âãå¼âêÜ-ÿcäæíÌíÍáÉèì0â®âìlè{à?Þ0ãèlÜâPëÿcä­ÜáÚäæê Éö ;ÝÅÝ(ö ¶äÌé2çÚãâ ÅßáÚÞlÿ-ßÈÜáÚâ"ãâPßçÚíÌÜßLÞ0õÍÜáÉâߣäæÝçÚí}èlÜäÌÞ2êjö

LáÚâÜáÚäæãëWå¼Þ2êÉë¡äÌÜäæÞ0êWçÚêfë¡âã®ÿcáÚä}åáÜáÚâUÝÅÞëÚâí¶ÿÈè2ß-ãçÚêWä}ß-ÜáÉèlÜ®Þ{õbÜáÉâçÚêÚäÌõuÞ0ãÝ(ùQíÌÞlÿÈâãcÜâÝÅà?âãèlÜçÉãâ è0å é0ãÞ0çÉêÉë

é2è0ßÆÿcä­ÜáÜáÉâUäæêÉå¼íæçÉßäÌÞ2êWÞ{õbÜáÚâ ¸ð ^þ ëÚäæߣÜãä ç¡ÜäæÞ0êWÞ0õNë¡ãÞ0àÚíæâ¼Ü8ߣä â=ßï ¶äæéÉö ó¼ö LáÚâPãâäæß®èÂí}è{ãé0âßàÚãâPè0ë(Þ0õNë¡ãÞ0àÚíæâ¼Ü

ë¡äæè0ÝÅâ¼ÜâPãßPù0ãè{êÉé0äæêÚé®õuãÞ2Ý íæâPßßbÜáÉè{ê Éö #Ý ÜÞé2ãâ=èlÜâãIÜáfè{ê+ú #Ý(ùãè0êÉë¡Þ2Ý;íæîUè2ßßäæé0êÚâ=ëÜÞâPè2åá/ë¡ãÞ2àÚíæâ¼ÜEäæê2ÜãÞ¡ë¡çfå¼âPë

äÌêÜÞWÜáÚâ+ßäæÝçÚí}èlÜäÌÞ2êjö ¡àfâPãäæÝÅâêÜè0í^ëÚè{Üè(äæêÉë¡ä}åè{ÜâÂíæä­ÜÜíæâåÞ0ããâPíæè{ÜäæÞ0ê âÜÿ^âPâêë¡ãÞ0àÉíÌâÜߣä â+è0êÉëºë¡ãÞ0àÚíæâ¼ÜUì0âíæÞ¡å¼äÌÜî0ù

è{êÉë+ÜáçÉßLÜáÚâ8ÜÿÈÞ;àfè{ãè{ÝÅâ¼ÜâãßÈè0ãâ8ë¡â=å¼Þ0çÉàÚíÌâ=ë#ö

LáÚâíÌÞ¡åè{ÜäæÞ0êèlܸÿcáÚäæåá(ÜáÚâÝ/è Þ2ãäÌÜî+Þ0õEë¡ãÞ2àÚíæâ¼ÜßÆë¡âPßÞ0íæìlèlÜâ8õuÞ2ã-ÜáÚäæ߸ߣâÜÆÞ{õbÞ2àfâPãè{ÜäæêÚéÂå¼Þ2êÉë¡äÌÜäæÞ0êÉßcä}ß-íæâPßßÆëÚâ ÉêÚâ=ë#ö

Û ßä =è íæâWõuãè0å¼ÜäæÞ0ê Þ{õÜáÚâ`ë¡ãÞ2àÚíæâ¼ÜßáÉèì2âèßç Âå¼äæâêÜíæîÖíÌÞlÿ ßä PâÀßçÉåá ÜáÉèlÜ·âìlè{à?Þ0ãèlÜäÌÞ2ê ÞåPå¼çÚãßÂÿcäÌÜáÉäÌêeߣâPì0âãè{í

Ý;ä}å¼ãÞ2ßâPåÞ0êÉëÉß^Þ0õ¶âPêÜâãäæêÚé;ÜáÚâàÉíæè2ߣÝ/èÚö LáÉâPßâë¡ãÞ2àÚíæâ¼ÜßcëÚÞ/êÚÞ{Ü-áÉèì2â"ߣç ÂåäÌâPê2ÜcÜäÌÝÅâ"ÜÞÂߣäæé0êÉä fåPè{êÜíæîÂà?âêÚâÜãèlÜâ8ÜáÚâ

àÚíæè2ߣÝ/è â¼õuÞ0ãâë¡â=ߣÞ2íÌìlèlÜäÌÞ2êÞ¡åPå¼çÚãßö ÆÞlÿ^âPì0âã=ùÜáÚâ"Ý/è Þ0ãä­ÜîÂÞ0õOÜáÚâë¡ãÞ0àÚíæâ¼Üßcè{ãâ8íæè0ãé2âãLäÌêßä Pâ0ùÉè0êÉë+ÜáÚâßäæÝçÚí}èlÜäÌÞ2ê

ߣáÚÞlÿ-ß^ÜáÉèlÜ Uà?âãå¼âPêÜLÞ0õOÜáÚâë¡ãÞ0àÚíæâ¼ÜßLâìlè{à?Þ0ãèlÜâ¸ÿcäÌÜáÉäÌêúÚö UÝÅÝ Þ{õ¶ÜáÉâ"êÚÞ íæâ®â ¡ä­Ü=ö

¶äæêÉè{íæíÌî2ùÜáÚâ8ߣäæÝçÉíæè{ÜäæÞ0êÂÿLè0ßNãçÚêçÉßäÌêÚéÜáÚâ è2å é2ãÞ2çÚêÉë;é2è2ß^åÞ0ããâ=ߣà?Þ0êfë¡äÌêÉé8ÜÞUÜáÚâÆÜâÝÅà?âãèlÜçÚãâ=ßùàÚãâPßßçÚãâ=ßùè{êÉë

üÉÞlÿ-ßàÚãâPßâêÜäæêºÜáÉâ+ðñÈòÿcäÌÜáºÜáÚâ ¸ð ^þ ë¡ä}ߣÜãä çÚÜäæÞ0êÞ0õcëÚãÞ2àÚíÌâÜßïåè2ߣâ ÉùbߣâPâ ¶äÌéfö 2ó³öÛ¸ßÿcäÌÜáºÜáÚâø #Ý

ë¡ãÞ2àÚíæâ¼ÜÆåè2ߣâ=ßùÜáÚâà?Þ0äæêÜÆèlÜ-ÿcáÚä}åá ;à?âãå¼âêÜ-Þ0õOÜáÚâë¡ãÞ0àÚíæâ¼ÜßLáÉèì0â"âPìlè{à?Þ0ãèlÜâ=ë+ä}ßLõè0ã£ÜáÚâãLõuãÞ0Ý ÜáÚââ ¡ä­Ü-êÚÞ PíÌâ"Þ0õ

ÜáÚâ ¸ð ^þeÜáÉè0ê+õuÞ2ãLÜáÚâåPè0ßâ¸Þ0õ¶çÚêÉä­õuÞ2ãÝ(ù ç¡Ü-íæÞlÿÈâãÈÜâPÝ;à?âãèlÜçÚãâ0ù è2å é2ãÞ2çÚêÉë/éè0ßPöIðrêÜáÚä}ßcåè0ßâ0ùÜáÚâ Uà?âãå¼âêÜ

ë¡ãÞ2àÚíæâ¼ÜÆâPìè0àfÞ2ãè{ÜäæÞ0êà?Þ0äæêܸä}ßÆíæÞ¡åèlÜâPë ÉöÌøÝ;Ý äæêÜÞÂÜáÚâUßäæÝçÚí}èlÜäÌÞ2êWë¡Þ0Ý/è{äæêjö -ÞlÿÈâì0âPãPùfíæè0ãé2âãÆè0êÉë·õè0ߣÜâPã®ëÚãÞ2àÚíÌâÜß

åè{ê·ãâÝ/è{äæêäæê·ÜáÚâ"àÉíæè2ߣÝ/è;çÚà·ÜÞ(ø0ö Åå¼Ý õuãÞ2Ý ÜáÚâ"êÉâ çÚíæä âãLÜäÌàÍö

âPíÌâ=å³ÜâPë åè0ßâPßÜáfèlÜ/çÉßâPëºÜáÚâßÜè{êÉëÉè{ãëºâìlè{à?Þ0ãèlÜäÌÞ2êÝÅÞ¡ë¡âícÿÈâãâ+ãâà?âPè{ÜâPëçÉßäÌêÚéÀÜáÉâ EÞ2çÚêÚé0ôñÈè0ãâPî ï äæêÚâÜä}åPó

Ý;Þ¡ë¡âPíEÞ{õLë¡ãÞ0àÚíæâ¼ÜâPìè0àfÞ2ãè{ÜäæÞ0êjö LáÚâ äæêÚâ¼ÜäæåÅâPìè0àfÞ2ãè{ÜäæÞ0êÀÝ;Þ¡ë¡âPíEÿLè0ß8çÉßâPëÜÞWåPè{í}å¼çÚí}èlÜâUÜáÚâ/âìlè0àfÞ2ãè{ÜäæÞ0êWÜäÌÝÅâ/Þ0õ

ë¡ãÞ2àÚíæâ¼ÜßLÿcäÌÜá·ÜáÚâ Æð Nþßä Pâ"ë¡äæߣÜãä ç¡ÜäæÞ0ê(äæê·è/úÚù

çÚêÚäÌõuÞ0ãÝ âPêìäæãÞ0êÚÝÅâêÜcè0ßLÿÈâíæíjè0ßcè ¸ð NþëÚãÞ2àÚíÌâÜ-ߣä â

ë¡äæߣÜãä ç¡ÜäæÞ0êäÌêÜáÉâ¸ðñÈòIö LáÚâ®àfÞ2äÌêÜcèlÜLÿcáÚä}åá Uà?âãå¼âêÜLÞ{õjÜáÚâ8ë¡ãÞ2àÚíæâ¼ÜßLë¡â=ߣÞ2íÌìlè{ÜâÆä}ßÈíÌÞ¡åPèlÜâ=ë+è{ÜcúÚö úÝ;Ý õuãÞ2Ý ÜáÚâ

êÚâ çÉíÌä âPãÆÜäÌàõuÞ2ãÆÜáÚâðñÈò è0å é0ãÞ0çÉêÉë·é2è0ß-ÜâPÝ;à?âãèlÜçÚãâPßÆè0êÉëWè{ÜUø0ö²úÅÝÅÝ õuãÞ2Ý ÜáÚâUêÚâ çÉíÌä âPãÆÜäÌàõuÞ0ã-ÜáÚâ;ú

çÚêÚäÌõuÞ0ãÝ è2å é2ãÞ2çÚêÉë/éè0ßcåÞ0êÉë¡äÌÜäæÞ0êÍö

LáÚâ`âìlè0àfÞ2ãè{ÜäæÞ0êÖÜäæÝÅâ`è2ß+Þ Üè0äÌêÉâPë ÿcäÌÜáTÜáÚâ EÞ0çÚêÉé{ô£ñÈè{ãâî Ý;Þ¡ë¡âPí®ëÚä Qâãß(ߣäæé0êÚä fåPè{êÜíæîõuãÞ0Ý ÜáÉèlÜ·Þ Üè{äæêÚâPë

çÉߣäæêÚé+ÜáÚâÅå¼Þ2ê2ÜäÌêçÚçÉÝ ÝÅÞ¡ë¡âPíYö LáÚâ EÞ2çÚêÚé0ôñÈè0ãâPîÂÜãâPè{ÜÝÅâêÜ®ÿÈè2߸ë¡âPãäæì0â=ë·õuÞ0ã8è+åPè0ßâäÌêÀÿcáÚä}åáÜáÚâÅë¡âPìä}èlÜäÌÞ2ê(õuãÞ2Ý

è{ê`âPýçÚäæíÌä ãäÌçÚÝ ß£äÌÜçfèlÜäæÞ0êä}ß"ãâí}èlÜäæì0âPíÌîWßÝ/è{íæí-÷­ø lûyö LáÚâÂßäÌÝUçÚíæè{ÜäæÞ0êÉß"ßáÚÞlÿ ÜáÉè{Ü îíÌÞlÿÈâãäÌêÉé+ÜáÚâ è0å é2ãÞ2çÚêÉëWéè0ß

ÜâÝÅà?âãèlÜçÚãâ·ÜÞ`íæâPßßUÜáÉè0êø0ù ÅùIÜáÚâãâPßçÚíÌÜß;Þ{õ¸ÜáÚâ äæêÚâ¼Üäæå·âPìè0àfÞ2ãè{ÜäæÞ0ê!Ý;Þ¡ë¡âPí-å¼Þ2êì2âãé0âÿcä­Üá!ÜáÚÞ2ßâ(Þ{õ¸ÜáÚâ

farther than the droplets in the lower temperature, uniform gas. Any increase

in evaporation rate due to higher

Æ

$

temperatures leads to a shorter residence time

of

the

droplet

in

the

plasma;

however,

this is more than# offset

<

by the acceleration provided by the nebulizer

gas.

The average droplet will penetrate the plasma to 1.5 mm

)!

P!

(indicating

an average residence time of 0.12ms,

40 percent

shorter than in the low temperature simulation),

:.$!

² !

2,

while

90

percent

will

have

evaporated

within

6.0

mm.

Figure

3 shows the results of the simulation. ?

The third condition underGwhich

the model was run is that of

the

uniform,

lower temperature background

+,

<

gas with the inclusion of the DIHEN

distribution of droplet

sizes (Fig. 4). There is a large spread of droplet

(! <%

!%

diameters, ranging from

less than 0.5 /xm to greater than 20 /xm, randomly assigned to each droplet introduced

C)

into the simulation. Experimental data indicate little correlation between droplet size and droplet velocity,

and thus the two parameters are* decoupled.

The

desolvate for this set of operating conditions is less defined.

location at which the majority of droplets

>

A sizable fraction of the droplets have

a sufficiently low size such

within several

2

> that evaporation occurs

microseconds of entering the plasma.

These

droplets

do

not

have

sufficient

time

to

significantly

penetrate the

)

plasma before

the droplets$are

larger

in size, and the simulation

.4! desolvation occurs. However, the majority of

6

shows

that 90 percent of the droplets evaporate? within 2.3 mm of the nozzle exit.

,

Finally, the simulation was run using

the

background gas correspondingto

thetemperatures,

pressures,

and

,

Y!C

%

flows present in the ICP with the

distribution of droplets (case 4, see Fig. 5). As with the 410

7.$DIHEN

!

/xm

droplet

cases,

the point at which 90 percent of the droplets have evaporated

is farther from the exit

:

?

:.$! nozzle of

the DIHEN than for the case of uniform,

but lower temperature, background

gas. In this case, the 90 percent

7

<

droplet evaporation point is located 3.1 mm into the simulation

domain. However, larger and faster droplets

can; remain in the plasma up to 1.3 cm from the nebulizer tip.

³

+

Selected cases that used the&standard

evaporation model were repeated using the Young-Carey (kinetic)

model of droplet :evaporation.

The kinetic evaporation

model was used to calculate the&evaporation

time of

!4!$!K5

droplets with the DIHEN

size

distribution

in

a

2,000

K

uniform

environment

as

well

as

a

DIHEN

droplet

size

>

.$!

distribution

in the ICP. The point

at which 90 percent of the droplets desolvate is located

at 2.2 mm from

the5

?

$!$!4!

nebulizer tip? for the ICP background gas temperatures and at 1.2 mm from the nebulizer tip for the 2000 K

uniform

background gas condition.

}³

The evaporation time as

obtained

with the Young-Carey model differs significantly from that obtained

:³

using the continuum model. The Young-Carey

was derived for a case in which the deviation

from

Y. treatment

(

?

an equilibrium situation is relatively

small [19]. TheCsimulations

show that by lowering the background gas

!$!$!}5

temperature to less than 1,000 K, the results of the kinetic evaporation model converge with those of the

250

Droplet Number Density

Droplet Evaporation Rate

1.2

E

1

0.8

o

0-

0.6

i

"O

0.4

CO

DC

0.2

2

3

Axial Position, mm

FIGURE 3. Droplet number density in m~3 and evaporation rate in m~3 s~l for a 10-pm uniform droplet distribution

in a background gas with temperature gradients identical to that of an ICP.

continuum evaporation model. This highlights the need for a kinetic-based evaporation model designed to give

adequate solutions for droplet evaporation in situations that are far from equilibrium.

CONCLUSIONS

The study presented in this report demonstrated the ability to formulate and construct a general gas-particle

evaporation model and simulation technique general to a wide range of Knudsen numbers and non-equilibrium

flow conditions. Several numerical algorithms were developed to efficiently model high pressure gas-surface

interactions and have been incorporated into the DSMC method. Two specific droplet evaporation models

were considered and compared. The numerical scheme is sufficiently general to provide a framework for future

extensions of the two phase flow modeling that will incorporate droplet condensation.

The results of the simulations show that the depth to which a droplet penetrates the plasma is, in general,

less than 1 cm. The total time of evaporation agrees with that predicted in reference 6. However, the model in

reference 6 did not include droplet transport and thus a full comparison is not possible. The plasma, however,

is approximately 5 cm in length, and therefore desolvation processes can occupy 20 percent of the analyte's

lifetime in the plasma. Considering that the analyte must then undergo the processes of evaporation to the gas

phase, atomization, excitation, and ionization before it can be detected, a shorter time to desolvation would

be preferred.

It can be seen that the high plasma temperatures lead to efficient desolvation; however, high gas velocities

cause the analyte to penetrate the plasma to a higher degree. Although a lower gas velocity would lead to

slower droplets, the nebulizer would be less efficient, producing larger droplets. Further studies of the design

trade-offs between these two effects are necessary.

Finally, it can be seen that a more inclusive droplet evaporation model is required. Although the continuum

model is likely to give accurate results, a particle-based method would be more comprehensive. Since the

situation under study is dominated by continuum gas conditions, the continuum evaporation model can be used

to give an acceptable desolvation rate. However, the influence of smaller droplets (higher Knudsen number) in

terms of ICP/DIHEN performance and related plasma and combustion processes is still under investigation.

251

Droplet Number Density

1

0.8

0.6

0.4

0.2

Droplet Evaporation Rate

E

S

I

1

0.8

0.6

0.4

0.2

Axial Position, mm

FIGURE 4. Droplet number density in m~3 and evaporation rate in m~3 s~l for a droplet size distribution representative of the DIHEN in a uniform 2000 K background gas.

REFERENCES

1. A. Montaser, Ed., Inductively Coupled Plasma Mass Spectometry, VCH, New York, NY, 1998, 964 pages.

2. A. Montaser and D. W. Golightly, Eds., Inductively Coupled Plasmas in Analytical Atomic Spectrometry, 2nd Ed.,

VCH, New York, NY, 1992, 1017 pages.

3. C. M. Benson, S. F. Gimelshein, D. A. Levin, and A. Montaser, Simulation of Droplet-Gas Interactions in an

Inductively Coupled Plasma Using the Direct Simulation Monte Carlo Method, AIAA Paper 2000-2431, June

2000.

4. J. A. Horner and G. M. Hieftje, Computerized Simulation of Mixed-Solute-Particle Vaporization in an Inductively

Coupled Plasma, Spectrochimica Acta 53B, 1235-1259 (1998).

5. J. A. McLean, Hao Zhang, and A. Montaser, A Direct Injection High-Efficiency Nebulizer for Inductively Coupled

Plasma Mass Spectrometry, Anal. Chem. 70, 1012-1020 (1998).

6. J.S. Decker, H. J. Dietze, J. A. McLean, and A. Montaser, Ultratrace and Isotope Analysis of Long-Lived Radionuclides by Inductively Coupled Plasma Quadrupole Mass Spectrometry Using a Direct Injection High Efficiency

Nebulizer, Anal. Chem. 71, 3077-3084 (1999).

7. B. W. Aeon, J. A. McLean, and A. Montaser, A Large Bore Direct Injection High Efficiency Nebulizer for Inductively

Coupled Plasma Spectrometry, Anal. Chem. 72, 1885-1893 (2000).

8. J. Mostaghimi, P. Proulx, and M. I. Boulos, An Analysis of the Computer Modeling of the flow and temperature

fields in an Inductively Coupled Plasma, Numerical Heat Transfer 8, 187-201 (1985).

9. M. Cai, D. A. Haydar, A. Montaser, and J. Mostaghimi, Computer Simulation of Argon-Nitrogen and ArgonOxygen Inductively Coupled Plasmas, Spectrochimica Acta 52B, 369-386 (1997).

10. G. A. Bird, "Molecular Gas Dynamics and the Direct Simulation of Gas Flows," Clarendon Press, Oxford, 1994.

11. M. S. Ivanov, G. N. Markelov, and S. F. Gimelshein, Statistical Simulation of Reactive Rarified Flows: Numerical

Approach and Applications, AIAA Paper 98-2669, June 1998.

12. Ivanov, M.S., and Rogasinsky, S.V., "Analysis of the numerical techniques of the direct simulation Monte Carlo

method in the rarefied gas dynamics," Soviet J. Numer. Anal. Math. Modelling, Vol. 3, No. 6, 1988, pp. 453-465.

13. A. H. Lefebvre, "Atomization and Sprays," Hemisphere Publishing, New York, 1989.

14. W. C. Hinds, "Aerosol Technology: Properties, Behavior, and Measurement of Airborne Particles," John Wiley &;

Sons, New York, 1982.

15. N. C. Clampitt and G. M. Hieftje, Investigation into the Mechanism of Desolvation of Sample Droplets in Flame

Spectrometry, Anal. Chem. 44(7), 1211-1219 (1972).

16. E. M. Sparrow and J. L. Gregg, The Variable Fluid-Property Problem in Free Convection, Tram. ASME 80,

879-886 (1958).

252

Droplet

DropletNumber

NumberDensity

Density

1

0.8

E+1

0.4

3.

82

6.36

1.14E+12

0.6

E+

1

1.2

1

7E

+1

1

1

0.2

Radial Position, mm

DropletEvaporation

Evaporation Rate

Rate

Droplet

1

E

0.8

E+

0.

05

_

0.4

0.4

(0

QC

5.

55

1.67E+05

89

3.

0.6

E+

0

4

0.2 *

0.2

Droplet

È¢ =2«­¤bnumber

§{¯ª®Ã¡¢¶density

¬0§©r¥²¤Y±"¥¦in§Uªm~ and

§¬"Axial

PP¡Position,

P¢£¼¤¥¦ =§mm

¢£¤È¥¦in§ªm~ s~l

© N¨} ¢EaÆdroplet

¬0¢ =2«¦¤I©r¥ cdistribution

¬0¥¦©y¤r¢¥­Ã2¯2¤¥¦ =§"represen¢0¢©r§

FIGURE

5.

evaporation

¤tative

£¼¤¥¦cof P¨Qthe

¤2 DIHEN

LÎ in¥¦§Åa®background

ÃP°£Á{´P¢ =¯2§¬gas

´P©EµEwith

¥²¤;¤temperature

ª"¡¢£¼¤¯2¢L´gradients

¢£=rate

¬0¥­§{¤©E¥­identical

¬2§{¤¥¦°³«Éfor

¤to ¸¤that

¤N of¨jPan§Åsize

ÎyICP.

»IÏQ¾

11

c2d?eGfKg:hvø

^J

¾

0¾

0¾

0¾

J

ÙÂÚ

2

Axial Position, mm

3

3

Ù>Ú

3

Ù

Z

ßÞ

$V

k^QRT

¸¾ j¾ ^¯Ã2⣬ ¸¾ b¾ ȧ§l± {§¬¿Æ¾ ¶¾¹;¥­«¦«¦© ^¢ =«¦¤ ÍPP¡ ¢£¤¥¦ =§ Ú°¤©b ¨jf¢£§©r¥¦§l¤©EP§¬ O¢¥­PÃ2«¦cÏj¢ P¡¢r¤¥¦©

£|2~ -orwP~ wx£x8msrwP|2x ³os

¾

ƾ2Ï#¾»I¢± ¡¾¹¾ ^±0¯ª"¥ 0P§¬ Ú¾2¿Nª"³¬ 0ÏQ =©y¤ §{¯°«¦³¼¤¥­ P§ ^¢ ³µb¤Å P¨?ʤ¢^¹;¥­°¢ {¬0¢ =2«¦¤©È¥¦§ {¯¡¢©¼¤¯2¢£¼¤³¬ L©

¹;¥ {¤¯2¢© ¶¿ ¹; =«¦°¯2«­¢ 0¥¦ª®¯2«Ì¼¤¥¦ =§ l¤¯¬0± £|2~ -orwP~ +wPxxmsrwP|2x ³os

¾

0¾ ^¾ ¶ P¯§´ NI+»¶ P§¬2§©¤¥¦ P§P§¬ ÍPP¡ ¢£¤¥¦ =§ P¨ É¥­½{¯2¥­¬ È¢ P«¦¤©¥­§Ïͯ0¢ ¶¡ =¯2¢U¼¤Å¿E¢Ã¥²¤r¢£¢r±Äc§{¯¬0©r§

^¯ª¸Ã¡¢ £|~ ÆorwP~ wPxx"msywP|x ³os

¾

0¾ ^¾ O =¯2§´ lI^»¶ =§¬2§2©¤¥¦ =§P§¬ ÍPP¡ ¢£¤¥¦ =§ ¨ É¥­½{¯2¥­¬ È¢ =2«­¤©I¤¶¿N¢Ã2¥²¤r¢£¢r±8Äc§{¯¬2©r§ ^¯ª¸Ã¡¢j¥¦§8¤NÏj¢©r§°

¨ÍP§UÎA§¢r¤ LP© £|2~ -orwP~ wx£x8msrwP|2x ³os

¾

Z Ö 2S

4ï

4k

àì

4Q

4J

*à

4_

?àÂJ

)Q

Q

0ì

?à

17. á G.ú

L.$ú

Hubbard,

V, E. Denny,

and A. F. Mills, Droplet Evaporation: Effects of Transients and Variable Properties,

ÿ

/ê

^iÆàÆZ[6[YaVÑZ?[Y[6XFZ?W Ö U6L

Int. J. Heat*à>Mass

Transferöà 18,N 1003-1008

(1975).

Z?X ì

N

ÂB

à

çV

(S

N

&S

18. V.#÷ P. Carey,

S.

M.

Oyumi,

and

S.

Ahmed,

Post-nucleation

Growth

of Water Microdroplets

in Supersaturated Gas

^N

(N

*àPá

ú$úÃÿ

/ê

Ý>üÃFZ[ Là>\6a6WYaV\b [ Ô

FZW6W Ö L

Mixtures: A$à Molecular Simulation Study,

Int. J. HeatMass

Transfer 40(10), 2393-2406

(1997).

Z?W )ô )H Õ

sQ

ï

}J

ì

19. T J. B. Young,

The Condensation

and Evaporation of Liquid Droplets in a Pure Vapour at Arbitrary Knudsen

àPá

ú$úÃÿ

Rê

~Ü$Ý`F Ö LàÃZ Ô bYWVZ Ô6Ô Z0FZW6W$ZL

Int.

(1991).

\[ )Number,

ô H

Õ

4à J. Heat Mass Transfer

Q 34(7), 1649-1661

ï

J

T

20. J. B. Young,

The

Condensation

and

Evaporation

of

Liquid

Droplets

Arbitrary Knudsen Number in the Presence

ES

?àÆá

ú$ú

ÿ

/ê

~ÜÃFZ6ZLà>\6W6b$ZV\6WYU Ô

FZW6WYaYat

L

of an Inert Gas, Int. J. Heat Mass Transfer 36(11), 2941-2956 (1993).

253