Optimizing I/O Timing Using the LogicLock

Methodology in the Quartus II Software v1.1

Technical Brief 74

October 2001, ver. 2.0

Introduction

™

Altera Corporation

101 Innovation Drive

San Jose, CA 95134

(408) 544-7000

http://www.altera.com

http://www.altera.com/mysupport

This technical brief describes how the use of the LogicLock methodology, available in

®

the Quartus II software v1.1, helps meet the input/output (I/O) performance

requirements of a design for APEXTM 20K, APEX 20KC, APEX 20KE, and APEX II

devices. This performance is achieved through the use of LogicLock timing and

placement constraints, together with the Optimize I/O cell register placement for timing

compiler setting in the Quartus II software v1.1.

Recommendations for Optimizing I/O Timing

Apply the constraints for I/O timing and logic assignments such as Fast Input Register

and Fast Output Register at the top level of the design hierarchy to affect register

placement for I/O timing. Altera suggests creating the LogicLock constraints intended

to work with the I/O timing constraints at the top-level of the design hierarchy. Altera

also recommends that pin location assignments are made to the design in order to use

the LogicLock constraints for I/O timing.

If an entity containing or feeding pins is assigned directly to a LogicLock region, the

fitter in the Quartus II software ignores the LogicLock region placement for the pins.

Hence, the LogicLock region assignments do not support locking down pin

assignments from the hierarchy.

However, if a pin is explicitly assigned to a LogicLock region, the fitter honors the

assignment, providing the LogicLock region is locked. In this case, the fitter attempts

to place the pin on the row or column adjacent to the LogicLock region. An example of

this explicit pin assignment is to select the pin name using the Node Finder and assign

it to a LogicLock region.

Effects of Compilation Timing Settings

The Optimize I/O cell register placement for timing compiler setting and the I/O Timing

Driven Compilation (TDC) settings — clock setup time (tsu) or clock to output delay

(tco) — affect the placement of the registers. The compiler places the registers in or close

to the I/O cell to meet the individual I/O timing requirements. The I/O cell registers

are used only if there is no logic between the register and the pin.

Altera recommends making individual rather than global I/O timing constraints, so as

to only affect the placement of the registers with difficult I/O timing requirements.

A difficult-to-meet tsu requirement, e.g., tsu <= 4 ns, results in register placement in the

I/O cell. If the I/O cell register is not available, the fitter optimizes the placement of the

cell containing the register to achieve the best possible tsu. See Figure 1.

Altera Corporation

M-TB-074-2.0

1

TB 74: Optimizing I/O Timing Using the LogicLock Methodology in the Quartus II Software v1.1

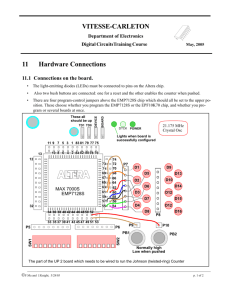

Figure 1. Input Pins

A difficult-to-meet tco requirement, e.g., tco <= 6 ns, results in register placement in the

I/O cell. If the I/O cell register is not available, the fitter optimizes the placement of the

cell containing the register to achieve the best possible tco. See Figure 2.

Figure 2. Output Pins

In APEX 20K, APEX 20KC, and APEX 20KE devices, the output register is given

priority for bidirectional pins. In the case of tight tsu and tco constraints on a

bidirectional pin, e.g., tco = 6 ns and tsu = 4ns:

■

■

■

The output register is placed in the I/O cell.

The input register is placed in the logic array block (LAB) adjacent to the pin.

The output enable register is placed in the LAB adjacent to the pin.

If there is insufficient logic or routing available for the LAB adjacent to the pin, the

™

MegaLAB adjacent to the pin is used.

In APEX II devices, all 3 registers are placed in the I/O cell. See Figure 3. If there is logic

between the register and the pin, the tsu, tco, and the minimum acceptable clock

frequency (fmax) requirements are optimized and the register placed to satisfy these

requirements.

For all of the above cases, the I/O register placement takes precedence over LogicLock

assignments to guarantee the I/O timing. However, the I/O register placement

influences the placement of the LogicLock constraints. As a result, the LogicLock

placement gravitates either toward the pins or registers, if necessary, in order to

achieve the fmax requirements while preserving the I/O performance.

2

Altera Corporation

TB 74: Optimizing I/O Timing Using the LogicLock Methodology in the Quartus II Software v1.1

This behavior applies to all LogicLock floating location assignments, i.e., auto-size

constraints and non-locked fixed size constraints with or without back-annotation.

Fixed size, fixed location LogicLock constraints do not have the flexibility to move

toward the pin or I/O register.

After successfully meeting the performance requirements using the LogicLock

methodology, a LogicLock back-annotation does not back-annotate the registers placed

in the I/O cell. The assignments which led to that implementation control the I/O

register placement.

Figure 3. Bidirectional Pins

Optimizing a Lower-Level Module for I/O Timing

In some design cases, it is necessary to optimize the performance of lower-level entities

with connections to I/O pins. In order to get a true indication of the module’s

performance and to enable preservation of the performance when the module is

exported to the top-level project, it is necessary to use the I/O timing constraints

together with LogicLock constraints.

The same techniques and rules apply as described earlier in the Effects of Compilation

Timing Settings section. For this optimization to work, after exporting the module to

the top-level project, the timing constraints and logic options must be applied to the

appropriate pins in the top-level project. Also, set the Optimize I/O cell register placement

for timing to the same state used when optimizing the lower-level module.

Conclusion

Use LogicLock constraints, timing constraints, and logic options to help meet the I/O

and fmax performance requirements of designs targeting APEX 20K, APEX 20KC,

APEX20KE, and APEX II devices.

®

101 Innovation Drive

San Jose, CA 95134

(408) 544-7000

http://www.altera.com

Altera Corporation

Copyright © 2001 Altera Corporation. All rights reserved. Altera, The Programmable Solutions Company, the stylized Altera logo, specific

device designations, and all other words and logos that are identified as trademarks and/or service marks are, unless noted otherwise, the

trademarks and service marks of Altera Corporation in the U.S. and other countries. All other product or service names are the property of

their respective holders. Altera products are protected under numerous U.S. and foreign patents and pending applications, maskwork rights,

and copyrights. Altera warrants performance of its semiconductor products to current specifications in accordance with Altera’s standard

warranty, but reserves the right to make changes to any products and services at any time without notice. Altera assumes no responsibility or

liability arising out of the application or use of any information, product, or service described herein except as expressly agreed to in writing

by Altera Corporation. Altera customers are advised to obtain the latest version of device specifications before relying on any published

information and before placing orders for products or services.

3