vii iii iv

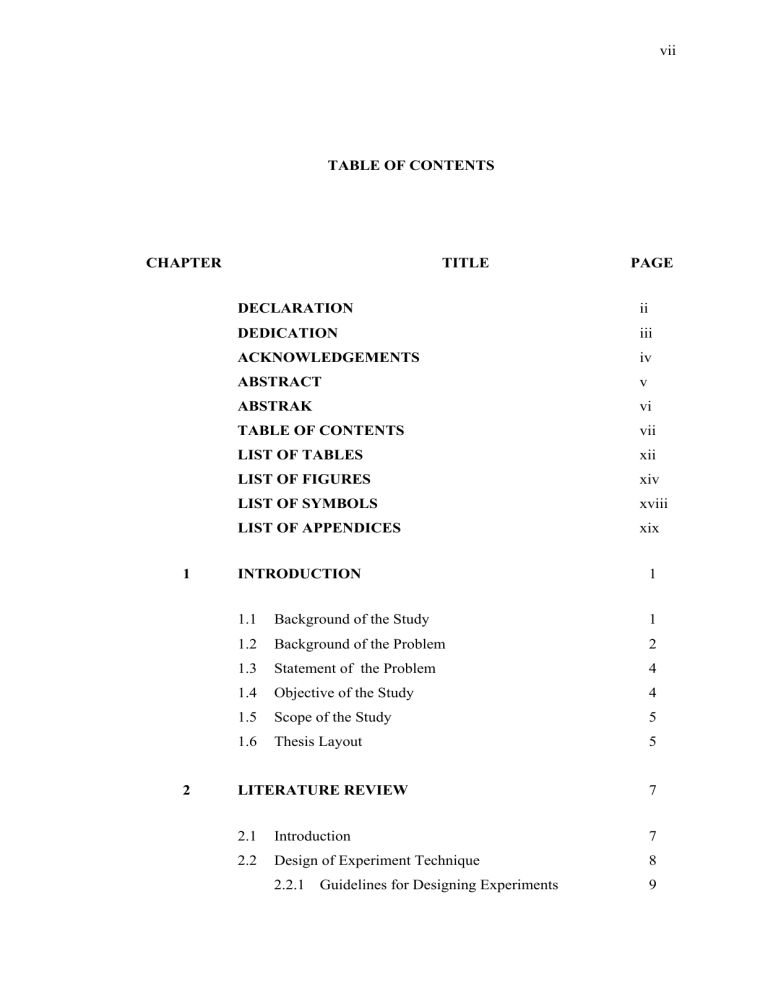

TABLE OF CONTENTS

CHAPTER

DECLARATION

DEDICATION

ACKNOWLEDGEMENTS

ABSTRACT

ABSTRAK

TABLE OF CONTENTS

LIST OF TABLES

LIST OF FIGURES

LIST OF SYMBOLS

LIST OF APPENDICES

TITLE

1 INTRODUCTION

1.1

Background of the Study

1.2

Background of the Problem

1.3

Statement of the Problem

1.4

Objective of the Study

1.5

Scope of the Study

1.6

Thesis Layout

2 LITERATURE REVIEW

2.1 Introduction

2.2 Design of Experiment Technique

2.2.1

Guidelines for Designing Experiments vii

PAGE vi vii xii xiv ii iii iv v xviii xix

1

4

4

1

2

5

5

7

7

8

9

viii

2.3

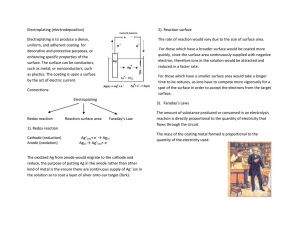

Electroplating Technique

2.3.1

Electrochemical Terms

2.3.2

Electroplating Equipment for Nickel and

Chromium Electroplating

2.3.3

Electroplating Process

2.3.4

Nickel Electroplating

2.3.4.1

Properties of Nickel

2.3.4.2

The Reason of Using Nickel prior

Chromium

2.3.4.3

The Basic of Nickel Electroplating

Process

2.3.4.4

Hydrogen Evolution and Cathode

9

10

11

14

15

15

15

16

2.3.4.5

Efficiency

Anode Efficiency

2.3.4.6

Controlling the Solution Composition

2.3.4.7

Controlling pH, Temperature Current

2.3.4.8

Density and Water Quality

Controlling Impurities

2.3.4.9

Nickel Plating Solution Composition

2.3.4.10

Description of Nickel Plating Solution

2.3.5

Compositions

Chromium Electroplating

2.3.5.1

Cathode Efficiency of Chromium Plating

Solutions

19

21

2.3.5.2

Chromium Plating Solution Composition 23

2.4

Historical Background of Diamond Coating 24

2.5

CVD Process

2.5.1

Advantages of CVD Process

26

27

28 2.5.2

Disadvantages of CVD Process

2.5.3

Five Major Characteristics of CVD Diamond

Coating 29

2.5.4

Hot Filament CVD Technique

2.5.4.1

Advantages of HFCVD

2.5.4.2

Disadvantages of HFCVD

22

31

34

34

17

17

17

18

18

18

3 ix

2.5.5

Substrate Material

2.5.5.1

Characteristic of Tungsten Carbide

(WC-Co)

2.5.5.2

Thermal Expansion Coefficient of

Substrate

2.5.6

The Effect of Major Parameters on HFCVD

34

34

36

Diamond Coating on WC-Co

2.5.6.1

The Effect of Methane Concentration

2.5.6.2

The Effect of Reactor Pressure

2.5.6.3

The Effect of Substrate Temperature

37

37

38

38

2.5.6.4

The Effect of Co Binder

2.6

Pre-Treatment Methods in Order to Suppress the Negative

39

Effects of Cobalt

2.6.1

2.6.2

Heat Treatments

Etching of Cobalt Binder

41

42

42

2.6.3

Micro-Roughening of WC-Co Surface Morphology 43

2.6.4

Forming Stable Cobalt Compounds

2.6.5

Giving a Suitable Diffusion Barrier Layer

44

(Interlayer) on the Substrates

2.6.5.1

Critical Review of Suitable Diffusion

45

Barrier Layer on the WC-Co Substrate 45

RESEARCH METHODOLOGY

3.1 Introduction

3.2

Preparing the Substrate Material

3.2.1

Cutting Workpieces by Means of the Linear

Precision Saw (Precision Cutter Machine)

3.3

3.2.2

Measuring the Surface Roughness

3.2.3

Measuring the Weight of Substrate

Pre-Treatment of Substrates

3.4

Electroplating Technique

3.4.1

Electroplating Equipments

3.4.1.1

Tank

54

54

55

62

63

63

56

58

59

59

4 x

3.4.1.2

Heater

3.4.1.3

Rectifier

3.4.1.4

Filter Pump

3.4.2

Nickel Electroplating

3.4.2.1

Nickel Plating Compositions

3.4.2.2

The Nickel Solution

3.4.2.3

Application of Current During Loading

3.4.3

Chromium Electroplating

3.4.3.1

Chromium Plating Compositions

3.4.3.2

Preparation of the Chromium Solution

3.4.3.3

Characteristic of Anode Material in

Chromium Plating

3.4.4

Design of Experiment Technique

3.5

Mounting and Grinding the Substrate

3.6

Characterisation Technique (SEM)

RESULTS AND DISCUSSIONS

4.1 Introduction

4.2 Section One- Part One for Nickel Electroplating

4.2.1

Mathematical and Statistical Analysis

4.2.2

Response - Thickness of Deposition

4.2.2.1

ANOVA Analysis

4.2.2.2

Model Adequacy Checking

4.2.2.3

Normal Probability Plot

4.2.2.4

Main Effect and Interaction Analysis

4.3

Section One – Part Two for Nickel Electroplating

4.3.1

ANOVA Analysis for Deposited Thickness

Response

4.3.2

ANOVA Analysis for Adhesion-Test Time

Response

4.3.3

Results from Both ANOVA Analyses

4.4

Section One – Part Three for Nickel Electroplating

68

69

74

75

76

88

89

91

91

66

66

67

67

63

64

64

65

67

68

78

81

82

83

86

76

76

77

77

xi

4.4.1

Design Expert Output for Thickness of Coating

Response

4.4.1.1

ANOVA Analysis

4.4.1.2

Normal Probability Plot

4.4.1.3

Plot of Residuals versus Fitted Values

4.4.1.4

Surface and Contour Plots

4.4.2

Design Expert Output for Adhesion-Test Time

93

93

96

97

98

Response

4.4.2.1

ANOVA Analysis

99

99

4.4.2.2

Normal Probability Plot 103

4.4.2.3

Plot of Residuals versus Fitted Values 104

4.4.2.4

3D Surface and Contour Plot

4.4.3

Overlay the Contour Plots

4.4.4

Optimum Parameters Combination

4.4.5

Discussion

4.5

Section Two – Chromium Electroplating on

105

106

107

107

108 Nickel Coated Substrate

4.5.1

Design of Experiment for Chromium

Electroplating – Part 1

4.5.1.1

Discussion

4.5.2

Design of Experiment for Chromium

Electroplating – Part 2

4.5.3

Conclusion of Part 1 and Part 2

109

110

112

5 for Chromium Electroplating

CONCLUSIONS AND RECOMMENDATIONS

114

4.6

Final Results of Nickel and Nickel-Chromium Coating 114

4.6.1

SEM Results 115

122

5.1

5.2

Results and Conclusions

Recommendations

REFERENCES

Appendix A

122

125

126

132-134

xii

4.5

4.6

4.7

4.8

4.9

LIST OF TABLES

3.2

3.3

3.4

3.5

4.1

4.2

4.3

2.4

2.5

2.6

3.1

2.1

2.2

2.3

4.4

TABLE NO.

The ANOVA table for response thickness, R1

Factor and level interest for second part of nickel electroplating

Data for part two of nickel electroplating, (the second first-order model)

TITLE

Guidelines for designing an experiment

Materials and their suitable and unsuitable environments

Recommendations of nickel plating solution compositions

Recommendations of chromium plating solution compositions

Some of the outstanding properties of diamond

Typical conditions for diamond deposition in HFCVD

Compositions of nickel plating solution

Compositions of chromium plating solution

The initial factors and levels of interest for nickel electroplating

The second factors and levels of interest for nickel electroplating

Factors and levels of interest for chromium electroplating

Data for part one of nickel electroplating, the first-order model

ANOVA table for response thickness of deposition, R1

ANOVA table for adhesion-test time response, R2

Central composite design for part three of nickel electroplating

Computer output from design-expert for fitting a model to the deposited thickness response in third section of nickel electroplating experiment

Computer output from design-expert for fitting a model to the adhesion-test time response in third section of nickel electroplating experiment

PAGE

87

88

90

92

93

100

70

70

70

78

79

86

25

31

66

68

9

12

19

23

4.10

The optimum parameters combinations for thickness of coating and adhesion-test time responses for nickel electroplating on

WC-Co substrates

4.11

Factor and level interest for chromium electroplating

4.12

Initial data for chromium electroplating on nickel coated substrates

4.13

Plating time in minutes for chromium deposit of average thickness 1-3 micron for current density 12Amp/dm

2

according to the Canning Handbook

4.14

Final results for chromium electroplating on nickel coated substrates xiii

107

109

109

112

113

xiv

LIST OF FIGURES

2.1

2.2

2.3

FIGURE NO. TITLE

Schematic of nickel electroplating on tungsten carbide

Variation in cathode efficiency with current density

Schematic diagram of diamond nucleation and growth in CVD

2.4

2.5

2.6

process

Schematic of a hot filament assisted CVD diamond growth system

Schematic of the physical and chemical process occuring during diamond CVD

Conventional removing of Co from near surface regions of cemented carbides prior to deposition of diamond (left) and proposed method of Co deactivation (right)

2.7

2.8

2.9

Flank wear of diamond coated cutting tools after different pretreatment and coating procedures

Three-dimension profilometry images of wear tracks on WC-

Co, Cr-N-coated, and multilayer (Cr-N+ diamond) coated samples after 30 min dry sliding tests

Wear resistance of diamond coatings on boronized and aluminized insert tips in comparison to conventionally etched samples

2.10

Schematics of the phase transformation in the WCGC during the process of diamond deposition

2.11

Schematic of the surface engineering approach for fabrication of the nano-microcrystalline diamond film composite coating hard metal cutting tools

PAGE

16

22

30

32

33

44

47

48

49

51

53

2.12

Comparison of cutting performance for the microcrystalline and

Nano-micro composite diamond coated WC – 6 wt. % Co

3.1

3.2

3.3

3.4

3.5

inserts subjected to the surface

The outline of project

Row material of WC-Co (before cutting)

Sample of substrate (12×2 mm) (after cutting)

SOMET 4000 linear precision saw

Formtracer CS - 5000 (Roughness/Contour Measuring System) -

Mitutoyo

3.6

3.7

Balance - resolution-10 nanogram

BWT chamber for blasting

3.8

3.9

Harnisch + Rieth D-S 100A steam cleaner

Branson 2510 ultrasonic bath machine

3.10

The nickel and chromium electroplating equipments

3.11

Buehler automatic mounting machine

3.12

Scanning Electron Microscope (SEM) – Philips XL40

4.1

Normal probability plot of residuals 82

4.2

Half-normal probability plot of the effects for the response, R

4.3

The main effects plots for the thickness of coating response, R

4.4

The interaction plot for the thickness of coating response

4.5

Central composite designs for three factors

4.6

Normal probability plot of residuals for thickness of coating response, R1

4.7

The residuals versus the fitted values for the thickness of coating, R1

4.8

The contour plot for the thickness of coating response, R1

4.9

The three-dimensional response surface plot for the Thickness of coating response, R1

4.10

Normal probability plot of residuals for adhesion-test time response, R2

4.11

The residuals versus the fitted values for the adhesion-test time response, R2

4.12

Contour plot of adhesion-test time response, R2 xv

62

65

75

75

58

59

60

61

53

55

56

56

57

83

85

85

92

97

97

98

99

104

104

105

4.13

Three dimensional response surface plots for the adhesion-test time response, R2

4.14

Region of the optimum found by overlaying thickness of coating and adhesion-test time response surface for nickel electroplating on tungsten carbide substrate

4.15

Partial coating of chromium on nickel coated sample at current density 10Amp/dm

2

4.16

Tearing the nickel surface in high current density (20Amp/dm

2

) of chromium electroplating, (a) bath temperature = 40 ºC, (b) and (c) bath temperature = 50 ºC

4.17

Coating the chromium on all surfaces with a slight burning on the surface 15Amp/dm

2

4.18

Slight dull grey rough deposition of chromium in current density

= 12Amp/dm

2

, (a) bath temperature = 36 ºC and (b) bath temperature = 38 ºC

4.19

Bright deposition of chromium on all surfaces in current density

= 12Amp/dm

2

, (a) bath temperature = 40 ºC and (b) bath temperature = 42 ºC

4.20

Nickel coating on WC-Co substrate

4.21

Nickel and nickel-chromium coating on WC-Co substrate

4.22

The mounted cross-sectioned samples

4.23

SEM showing the cross-section and interface morphology and the thickness of nickel coated WC-Co when bath temperature =

70 ºC, current density = 24Amp/dm

2

, and plating time = 40 minutes

4.24

SEM showing the cross-section and interface morphology and the thickness of nickel coated WC-Co when bath temperature =

70 ºC, current density = 8Amp/dm

2

, and plating time = 60 minutes

4.25

SEM showing the cross-section and interface morphology and the thickness of nickel coated WC-Co when bath temperature =

60 ºC, current density = 6Amp/dm

2

, and plating time = 73.6 minutes xvi

105

106

110

111

111

113

114

114

115

116

117

117

118

4.26

SEM showing the cross-section and interface morphology and the thickness of nickel coated WC-Co when bath temperature =

60 ºC, current density = 6Amp/dm

2

, and plating time = 40 minutes

4.27

SEM showing the cross-section and interface morphology and the thickness of nickel coated WC-Co when bath temperature =

50 ºC, current density = 4Amp/dm

2

, and plating time = 60 minutes

4.28

SEM showing the cross-section and interface morphology and the thickness of nickel-chromium coated WC-Co when (for nickel; bath temperature = 58 ºC, current density = 4Amp/dm

2

, and plating time = 26.3 minutes) and (for chromium; bath temperature = 42 ºC, current density = 12Amp/dm

2

, and plating time = 15 minutes)

4.29

SEM showing the cross-section and interface morphology and the thickness of nickel-chromium coated WC-Co when (for nickel; bath temperature = 58 ºC, current density = 4Amp/dm

2

, and plating time = 26.3 minutes, thickness = 6.3µm) and (for chromium; bath temperature = 42 ºC, current density =

12Amp/dm

2

, and plating time = 15 minutes, thickness = 2.44

µm)

4.30

EDX analysis for nickel coating

4.31

EDX analysis for nickel-chromium coating xvii

118

119

119

120

120

121

xviii

LIST OF SYMBOLS

A - First factor or input variable investigated – bath temperature

(ºC)

Adeq. precision - Adequate precision

Adj. R

2

- Adjusted R-square

B - Second factor or input variable investigated – current density

(Amp/dm

2

)

C - Third factor or input variable investigated - plating time (min)

Cor. Total - Totals of all information corrected for the mean

CV

Prob > F

- Coefficient of variation d.f. - Degrees of freedom

Pred. R

2

- Predicted R-square

- Proportion of time or probability you would expect to get the stated F value

PRESS - Predicted residual error sum of squares

R1 - Coating thickness response (µm)

R2

R

2

S.D.

- Adhesion-test time response (second)

- Coefficient of determination

- Square root of the residual mean square

xix

LIST OF APPENDICES

APPENDIX TITLE PAGE

A Calculating the thickness of nickel and chromium coating on WC-Co 132