Journal of Computations & Modelling, vol.4, no.1, 2014, 39-51

ISSN: 1792-7625 (print), 1792-8850 (online)

Scienpress Ltd, 2014

Electric Machine Experimental Monitoring System

based on Labview Environment

Panayiotis Michalopoulos1, Christos Kalogrias2,

Fotis D. Kanellos3 and George J. Tsekouras4

Abstract.

It is widely accepted that contemporary scientific experimentation on electrical

machines requires extensive measurements and acquisition of various data. The

equipment used for this purpose is usually quite expensive and dedicated to a specific

application. In this paper the development of a programmable, versatile and

inexpensive system based on Labview environment is described. This is able to

perform an essentially limitless number of simultaneous measurements on any kind of

experimental or applied installation. Furthermore, the same system is able to perform

extensive signal conditioning and processing, in order to automatically produce

complex graphs and facilitate the drawing of conclusions. Finally, the same system

may actively control electrical equipment allowing for even more complex

experiments to be performed. In this case, an ac/ac converter supplies power to an

electric motor. Six differential voltages and six currents are measured and recorded in

real time, while power, total harmonic distortion etc are calculated, in order to

determine whether the use of the ac/ac converter is efficient or not.

Keywords: Data acquisition, LabView, measurement system, induction motor, power

electronics.

1

CDR (Eng) Hellenic Navy, Hellenic Naval Academy, Terma Hatzikiriaku, Piraeus, GR18539, Greece

E-mail:panos.michalo@gmail.com

2

LCDR (Eng) Hellenic Navy, Hellenic Naval Academy, Terma Hatzikiriaku, Piraeus, GR18539 Greece

E-mail:ckalogr@gmail.com

3

Lecturer, Production Engineering & Management Department, Technical University of

Crete, Chania, GR-73100, Greece

E-mail: fkanellos@dpem.tuc.gr

4

Lecturer, Hellenic Naval Academy, Terma Hatzikiriaku, Piraeus, GR-18539 Greece

E-mail: tsekouras@snd.edu.gr

40

Electric Machine Experimental Monitoring System

1. Introduction

The basis of any scientific experimentation is the ability to perform measurements.

The simplest phenomena on electrical machines are related to their steady-state

behavior. These can easily be studied with the use of common instruments like Vmeters, A-meters, oscilloscopes etc. However, when more complex phenomena need

to be studied like transient behavior, notches and harmonic distortion, then more

sophisticated equipment is required. Such instruments are multichannel oscilloscopes,

measurement recorders etc, which are very expensive and many times prove to be

inadequate.

The introduction of data acquisition devices solved all these problems by offering

accurate and high-speed equipment that can use regular PCs to store and process very

large amounts of measurements. Furthermore, they can provide interactive and smart

collection of data, accelerating and facilitating the work of the researcher.

2 What is a DAQ?

Today, commercial Data AcQuisition devices (DAQs) allow for the simultaneous

input of 16, 32 or more voltages at sampling speeds that range from a few kHz to

many GHz. Conversion from analog to digital is not a problem, because the resolution

provided can be quite high (24 bits or more). This data may be processed extensively

in a computer to provide real-time results with no effort.

Moreover, DAQ devices may also output several voltages to drive analog actuators.

This way, very complex experiments can be implemented. In addition to the above,

numerous digital inputs and outputs are also provided, allowing for multiple triggers,

switch activation etc.

Such multiple analog and digital input / output systems, with the processing power

provided by computers, can be networked together to form a cluster of virtually

infinite measuring potential.

There are several ways to program a DAQ device, using general purpose languages

like C++ or specific graphic environments like LabVIEW. The latter allows for the

creation of the so called “virtual instruments”, which can be fully customized. All

dataflow from measurement and data processing to data storage, results presentation

and signal output is programmed using graphic blocks, much like Matlab’s Simulink.

P. Michalopoulos, Ch. Kalogrias, F.D. Kanellos and G.J. Tsekouras

41

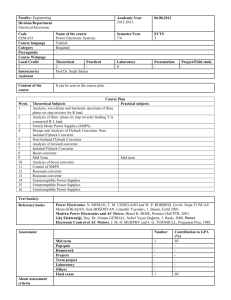

3 Developed DAQ System

3.1 The initial problem of energy efficiency study of topologies for

power converters & electrical motors

Modern warships are equipped with many induction motors of different nominal

powers ranging from a few hundred Watts up to several MW. Most of them are threephase squirrel type induction motors, with the exception of small one-phase motors

used in accommodation spaces and large multi-phase propulsion motors [1]. The

performance of the induction motor is quite satisfying when it is operating close to its

nominal power and speed [2].

However, its high starting current and low starting torque drastically reduce its

efficiency, especially if the motor repeatedly starts and stops only to run for short time

intervals. Electrical equipment manufacturers state that the use of power electronics is

the solution to achieve energy saving [3]. This is true because power electronics

significantly limit the starting current and its respective losses. They can also increase

the motor’s efficiency by supplying it with variable voltage and frequency, in order to

drive it on its optimum operating point for each load. This is calculated by a

specialized automatic control system.

On the other hand, power electronics cause power quality problems, like harmonic

injection. The existence of current and voltage harmonics in their output causes

additional power loss on the induction motor, because of magnetic hysteresis losses,

eddy currents on the core and of skin effect on copper windings. Also, the existence

of current harmonics in their input causes additional power loss on the cables and busbars, because of skin effect and operational problems in other electrical equipment.

Some of them are inaccurate operation of automatic control systems, flickering

phenomenon at fluorescent lamps etc.

3.2 The prototype data acquisition system

In previous work [4], an experimental setup was implemented to verify and

approximately quantify the efficiency of driving a motor with a power-electronics

converter. In this setup, a three-phase squirrel induction motor is driving an

electrodynamometer which represents the mechanical load (i.e. a pump, a fuel oil

42

Electric Machine Experimental Monitoring System

separator etc). This motor is powered by a regular three-phase power supply, either

directly or through an AC/DC/AC electronic converter. The basic topology and a

photo of the experimental setup are shown in Figures 1 and 2 respectively.

All six voltages are measured, in respect to the neutral, using differential voltage

probes with a transformation ratio of 1:200 (see Fig. 3). Also, all six line currents are

measured using current probes (clamps) with a transformation ratio of 1A:500 mV

(see Fig. 4). In order to amplify the weak current signal, each line is turned over the

clamp four times.

All these signals are collected and properly sampled by the heart of the system,

which is a data acquisition USB device (see Fig.5), with 16 multiplexed analog inputs

and a maximum combined sampling rate of 200 KS/s [5].

In this setup, 12 inputs are used and sampled at 13 kHz each. From these inputs,

measurements are acquired, processed, displayed and stored in bunches of 500

samples per input.

Public supply

400/230V, 50Hz

Power supply (inverter & stabilizer) 9 V d.c. for probes

prob

es

EMS8821-13

power

supply

MITSUBISHI

9V

d.c.

VVVA

FR-E540-0.4K~

EC

A

A

~

EMS8219-00

electrodynamom

eter

Lab-volt EMS882105 squirrel

induction motor

VVVA

9V

d.c. 6015

National Instr. DAQPad

A

EL

M~3

A

Figure 1. Detailed block diagram of the experimental setup

(the supply of the excitation winding of the electrodynamometer is omitted for simplicity).

P. Michalopoulos, Ch. Kalogrias, F.D. Kanellos and G.J. Tsekouras

43

Figure 3. HAMEG Instruments HZ-100

differential voltage probe.

Figure 4. Chauvin Arnoux E3N current probe.

Figure 2. Photo of the experimental

topology.

Figure 5. National Instruments DAQPad 6015

data acquisition device.

The inputs are multiplexed, meaning that they are not sampled simultaneously,

which could lead to erroneous results. However, since the time required to receive a

sample from every input is much smaller than the 0.02sec – that correspond to the

50Hz frequency of the mains – the measurements may be considered simultaneous.

All the above are adjusted and controlled by a PC connected to the DAQ device.

This PC is programmed using a block-diagram style environment called LabVIEW

(see Fig.6). With this one can create very versatile custom views of data

representation and control called Virtual Instruments (see Fig.7).

44

Electric Machine Experimental Monitoring System

Figure 6.

LabVIEW algorithm.

Figure 7.

Virtual Instrument showing instant voltages, currents and power per phase.

P. Michalopoulos, Ch. Kalogrias, F.D. Kanellos and G.J. Tsekouras

45

The algorithm created here performs the following:

Virtual presentation and data storage of instant line-to-neutral voltages vi(t), of

instant line currents ii(t) and of instant power pi(t) for the three phases i=a,b,c of the

converter input and the converter output with respect to time t (see Fig. 6). Taking

into consideration the transformation ratio of differential voltage probes AV, the

transformation ratio of current probes AI and the number of turns at the clamps

(turns), the instant power pi(t) is then calculated as:

A i t

pi t AV vi t I i i=a, b, c (1)

turns

Virtual presentation and data registration of root mean square (R.M.S.) line-toneutral voltages Vi , R.M.S. of line currents Ii and of active power Pin-i for the

three phases i=a,b,c of the converter input and the converter output with respect to

time (see Fig.8). The respective calculations for R.M.S. line-to-neutral voltages are

realized as:

Vi

t2

1

vi2 t dt

t2 t1 t1

T

k T t2 t1

NT k NT k NT

Vi

Vi

1 k NT 2

T

vi i

T i 1

k NT

1 NT 2

vi i

NT i 1

Where t2-t1=k∙T, k is an integer number and T is the period of the three-phase

supply voltage Va(t)- Vb(t)- Vc(t). Because of the multiplication factor AV of the

voltage probe, finally the respective values of R.M.S. voltages are equal to:

1 NT 2

Vi AV

vi i i=a, b, c (2)

NT i 1

46

Electric Machine Experimental Monitoring System

Figure 8. Virtual instrument showing root mean square values of line-to-neutral voltages,

line currents and active power per phase.

Similarly, the R.M.S. line currents are calculated taking into consideration the

transformation ratio of current probes AI and the number of turns at the clamps

turns:

t2

1

Ii

ii2 t dt

t2 t1 t1

T

k T t2 t1

NT k NT k NT

AI

1 NT 2

ii i i=a, b, c

… Ii

turns NT i 1

(3)

Respectively, the active powers per phase are calculated taking into consideration

the respective transformation factors of the probes:

Pi

t2

1

vi t ii t dt

t2 t1 t1

T

k T t2 t1

NT k N T k N T

… Pi

AV AI NT

vi i ii i

turns NT i 1

i=a, b, c (4)

The apparent power Stot and the active power Ptot are calculated using the following

equations:

P. Michalopoulos, Ch. Kalogrias, F.D. Kanellos and G.J. Tsekouras

Stot

Ptot

Vi Ii

(5)

Pini

(6)

i a ,b ,c

i a ,b,c

47

These calculations are used on the converter input and output measurements.

More parameters are then calculated. These are the power losses at the converter

Pconv_losses, the supply power factor cosφsupply (ignoring harmonic influences) etc:

Pconv _ losses Ptot _ in _ inverter Ptot _ out _ inverter (7)

cos supply

Ptot _ in _ inverter

Stot _ in _ inverter

(8)

3.3 Equipment of the experimental system

The experimental setup has been developed in the Electric Circuits Laboratory of

the Hellenic Naval Academy.

The parts used are the following:

a Lab-Volt EMS 8821-13 three-phase power supply with a variable output of 0 ÷

380V via auto-transformer, 3A/50Hz and a circuit breaker. This represents the

constant voltage supply of the motor.

a Lab-Volt EMS 8821-05 three-phase squirrel induction motor with 175W

mechanical power, 380V, 0.52A, 50Hz, 1360rpm.

a Lab-Volt EMS 8219-00 electrodynamometer with 0÷3N∙m torque and

0÷3000rpm rotational speed. The power supply of the excitation supply is:

220÷240V, 50Hz, 0.9A via a four-diode rectifier. It represents the mechanical load

of the motor.

a HIOKI 3404 digital rpm counter with a measurement range of 30 ÷ 99.990rpm.

a MITSUBISHI FR-E540-0.4K-EC AC/DC/AC converter, with 0.4kW active

power, 400V (380V÷480V) at 50/60Hz three-phase input voltage with permissible

AC voltage fluctuation 325 to 528V and frequency ±5%, rated output capacity

1.2kVA at 440V, three-phase output voltage 400V (380÷480V) at 50/60Hz [7].

48

Electric Machine Experimental Monitoring System

twelve isolated 12Vdc/1A power supplies electronically stabilized and protected

from overcurrent and overheat.

With this equipment another variable that can be calculated is the output load

power Pout , which is related to the torque Ts and the mechanical rotational speed a as

follows:

Pout Ts Ts [N m]

a [R.P.M.]

60

(9)

After that, the total system efficiency , which is the ratio between the output load

power Pout and the input power Pin can be estimated:

Pout

Ptot _ in _ inverter

(10)

Even more variables can be calculated such as power saving, spectrum analysis,

total harmonic distortion etc.

4 An indicative experiment

The steady state energy saving problem of a three-phase squirrel induction motor is

studied in three cases:

without power electronics converter (scenario 1),

with power electronics converter, but without any special frequency regulation

(output converter voltage frequency equals to 50 Hz) (scenario 2),

with power electronics converter, with voltage-frequency regulation with respect to

nominal output mechanical load (scenario 3).

The output mechanical load of electrodynamometer ranges between 0÷120W with

20W steps. The values of the 6 line-to-neutral voltages and 6 line currents of the three

phases are measured with the data acquisition (DAQ) system, the rotor speed of the

electrodynamometer with the HIOKI 3404 digital rpm counter and the torque with the

electrodynamometer’s indicator. The results are summarized in the following Figures

9 and 10.

P. Michalopoulos, Ch. Kalogrias, F.D. Kanellos and G.J. Tsekouras

49

60%

1800

1600

50%

1400

40%

1000

n [%]

a [R.P.M.]

1200

800

scenario 1

scenario 2

scenario 3

Poly. (scenario 1)

Poly. (scenario 2)

Linear (scenario 3)

600

400

200

30%

scenario 1

scenario 2

scenario 3

Poly. (scenario 1)

Poly. (scenario 2)

Poly. (scenario 3)

20%

10%

0%

0

0

20

40

60

80

Pout [W]

100

120

140

0

20

40

60

80

Pout [W]

100

120

Figure 2. Mechanical power load Pout vs Figure 3. Mechanical power load Pout total

motor speed a, for (1) without power motor efficiency , for (1) without power

power electronics

converter,

electronics converter without frequency electronics

converter

without

frequency

(3)

power

electronics

electronics

converter,

regulation, (3)

(2)

with power

with

electronics regulation,

converter and voltage-frequency regulation.

with

(2)

with

power

converter and voltage-frequency regulation.

From the results, it can be derived that the total system efficiency is worse when a

power converter is used without any frequency regulation. When voltage-frequency

regulation is used, the total system efficiency is better for small mechanical load. That

is because the losses of the converter harmonics are smaller than the power losses of

the motor operating at its nominal slip point.

5 Conclusions

DAQ devices are invaluable instruments for recording and utilization of large

amounts of measurements, when studying the transient and steady-state behavior of

electric equipment. Especially in the modern warships, which become more and more

all-electric, it is of particular interest to record simple parameters, like currents and

voltages. From them more values, like efficiency, can be calculated. This way,

equipment can be operated at low cost and its reliability can be increased.

140

50

Electric Machine Experimental Monitoring System

6 Future steps

In the future the following will be implemented:

The measurements of the mechanical load and the rotor speed will be added to the

data acquisition system. This way all necessary measurements will be recorded

simultaneously, increasing precision.

The measurements of the voltages and currents can be utilized for the study of the

supply’s and motor’s harmonic behavior.

The transient phenomena will also be studied in different scenarios and energy

saving results will be produced for different operating periods of the motor and

variable torque profiles.

The measurement process will be enhanced with emphasis to parameter calibration,

such as sampling rate etc.

The measurement system will be programmed to automatically be self-calibrated to

the bias values and the actual transformation rations of the voltages and the currents

probes.

7 Acknowledgements

The authors would like to thank Dr. I.K. Hatzilau, Emeritus Professor at the Hellenic

Naval Academy, for his overall contribution to the configuration of the Electric

Circuits Laboratory at the Hellenic Naval Academy.

Nomenclature

DAQ: Data AcQuisition system

References

[1] F. Terrien, S. Siala and P. Noy: Multiphase induction motor sensorless control

for electric ship propulsion, 2nd international conference on power Electronics,

machines and drives, PEMD-2004

P. Michalopoulos, Ch. Kalogrias, F.D. Kanellos and G.J. Tsekouras

51

[2] Th. Wildi: Electrical Machines, Drives, and Power Systems, 5th Edition,

Pearson Prentice Hall, New Jersey, 2002, p. 860

[3] St. Rudell: ABB Review special report motors and drives: Improving motor

efficiency, 1st edition, 2010.

[4] P. Michalopoulos, Ch. Kalogrias, F.D. Kanellos and G. J. Tsekouras:

Experimental investigation of energy saving using power electronics to

operate ship induction electric motors, 1st MARINELIVE Workshop on

Electric Machines & Power Converters, January 11-12, 2012, Athens, Greece

[5] National Instruments DAQPad 6015 user’s manual.

[6] MITSUBISHI Transistorised inverter, FR-E500 Instruction manual, 2000.