Companion II 8.3kV, 17.2kV and 23kV 12K - 40K Backup Fuses CERTIFIED

advertisement

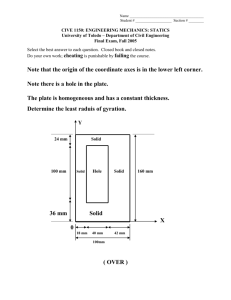

E No: None File Ref: 240-64 CP No.: CP9716 Rev. 02 Page: 1 of 9 CERTIFIED TEST REPORT Companion II 8.3kV, 17.2kV and 23kV 12K - 40K Backup Fuses Rev. 02 DATE: June 3, 2010 • ORIGINAL REPORT DATE: June 13, 1997 • © Cooper Power Systems, Inc. E No: None File Ref: 240-64 CP No.: CP9716 Rev. 02 Page: 2 of 9 Companion II 8.3kV, 17.2kV and 23kV 12K - 40K Backup Fuses CERTIFICATION Statements made and data shown, to the best of our knowledge and belief, are correct and within the usual limits of commercial testing practice. E No: None CP No.: CP9716 Rev. 02 File Ref: 240-64 Page: 3 of 9 Overview The Cooper Power Systems Companion II 12K through 40K fuses are designed to be applied as backup current limiting fuses. In this application, the Companion II fuse provides protection against high current faults and limits the peak current and the amount of let-through energy to the protected equipment. The CPS Companion II fuse is typically applied in series with an expulsion fuse. When applied in series with an expulsion or other type of low current interrupting device, the combination provides “full range” protection. Certification Tests as required by IEEE Std C37.41-2008 1. Interruption Tests at Line-to-Neutral Rated Voltage • Series 1 Rated Maximum Interrupting Current • Series 2 Critical Current • Series 3 Rated Minimum Interrupting Current 2. Temperature Rise Tests 3. Time Current Characteristic Tests 4. RIV Tests E No: None File Ref: 240-64 CP No.: CP9716 Rev. 02 Page: 4 of 9 INTERRUPTION TESTS Requirements Back-up current-limiting fuses are required to operate on high available fault currents and limit the fault current magnitude and energy. They must interrupt these fault currents so that the other pieces of connected equipment are isolated from the electrical distribution system. Objective The objective of these tests is to verify the interrupting performance of the Companion II fuse for applications at the respective voltage rating by testing according to the requirements specified in ANSI/IEEE C37.41-2008, clause 6.6 and C37.47-2000. Procedures These tests were run on production fuses which were assembled using standard methods and procedures. The testing was conducted at ambient temperature. Test Results The Companion II 12K – 40K fuses successfully interrupted each respective test current. The performance parameters are detailed in Table 1: Table 1: Interruption test results Test current Test Voltage close angle Part number A kV deg 8.3kV 12K 50600 8.3 8.3kV 12K 8.3kV 12K 50600 50600 2346 8.3kV 12K 8.3kV 12K Melt I²t Total I²t Total Energy Melt time Clear time Withstand X/R kA²sec kA²sec kJ msec msec (min) 40 35 5.30 9.56 22.0 0.360 --- 1 8.3 65 35 5.50 12.1 25.4 0.290 --- 1 8.3 8.4 65 7 35 12 5.85 4.31 11.7 9.32 24.2 61.0 0.290 3.283 ----- 1 10 2392 8.5 8 12 4.27 9.65 63.5 3.217 --- 10 8.3kV 12K 2360 8.4 9 12 4.33 9.08 60.1 3.320 --- 10 8.3kV 12K 489.8 8.35 --- 1.7 6.66 6.91 --- 27.800 29.800 10 8.3kV 12K 507.8 8.35 --- 1.7 6.82 7.12 --- 26.500 28.600 10 8.3kV 40K 50600 50600 8.4 8.4 20 55 30 30 59.2 60.0 124 160 116.0 149.0 0.900 0.670 ----- 1 8.3kV 40K 8.3kV 40K 50600 8.4 55 30 60.9 151 138.0 0.650 --- 8.3kV 40K 8280 8.3 7 12 58.3 140 243.9 --- --- 1 10 8.3kV 40K 8310 8.3 7 12 57.9 139 241.7 --- --- 10 8.3kV 40K 8.3kV 40K 8280 8.3 8 12 55.9 144 253.8 --- --- 10 1001 8.4 -97 2.1 261 267 20.4 262.040 268.880 10 1 8.3kV 40K 1002 8.4 43 2.1 250 255 20.3 246.850 253.930 10 17.2kV 12K 43500 17.3 40 35 5.40 10.0 50.4 0.370 --- 1 17.2kV 12K 43500 17.3 65 35 5.60 12.3 57.7 0.290 --- 1 E No: None File Ref: 240-64 CP No.: CP9716 Rev. 02 Page: 5 of 9 17.2kV 12K 43500 17.3 65 35 5.60 12.0 55.5 0.310 --- 17.2kV 12K 2380 17.6 11 12 4.43 10.7 143.8 3.129 --- 1 10 17.2kV 12K 2365 17.3 9 12 4.24 10.6 139.5 3.187 --- 10 17.2kV 12K 2373 17.4 11 12 4.16 10.7 141.3 3.078 --- 10 17.2kV 12K 510 18.0 -76 2.3 7.06 7.61 26.1 29.043 37.474 10 17.2kV 12K 502 17.9 -97 2.3 7.27 7.73 7.0 29.598 32.044 10 17.2kV 40K 43500 17.4 30 30 56.4 136 276.0 1.080 --- 1 17.2kV 40K 43500 17.4 55 30 57.1 164 341.0 0.890 --- 1 17.2kV 40K 43500 17.4 55 30 59.8 170 354.0 0.740 --- 17.2kV 40K 9390 17.2 4 11 56.0 144 475.7 3.215 --- 1 10 17.2kV 40K 9400 17.2 5 11 55.3 147 486.9 3.180 --- 10 17.2kV 40K 9390 17.2 7 11 54.7 152 499.6 3.085 --- 10 17.2kV 40K 1000 17.2 106 2.2 193 214 35.7 193.400 200.700 10 17.2kV 40K 1000 17.2 -91 2.2 225 232 64.4 205.700 217.100 10 23kV 12K 31000 23.1 40 35 5.10 9.24 70.2 0.460 --- 1 23kV 12K 31000 23.1 65 35 5.10 10.8 81.3 0.350 --- 1 23kV 12K 31000 23.1 65 35 5.40 10.8 78.2 0.370 --- 23kV 12K 2350 23.3 8 12 4.28 10.4 175.9 3.217 --- 1 10 23kV 12K 2360 23.4 8 12 4.12 10.2 177.2 3.169 --- 10 23kV 12K 2360 23.4 10 12 4.04 9.89 173.2 3.118 --- 10 23kV 12K 517 24.1 113 2.3 6.85 7.34 12.3 27.910 31.099 10 23kV 12K 500 23 -134 2.3 6.87 8.22 19.7 29.040 37.474 10 23kV 25K 31000 23 40 30 19.8 50.6 225.0 0.680 --- 1 23kV 25K 31000 23 55 30 21.4 56.1 250.0 0.630 --- 1 23kV 25K 31000 23 55 30 21.3 57.3 254.0 0.610 --- 23kV 25K 5470 23 16 12 17.2 45.7 316.8 2.809 --- 1 10 23kV 25K 5500 23 9 12 17.8 44.7 312.1 3.080 --- 10 23kV 25K 5470 23 10 12 17.0 45.8 323.3 3.075 --- 10 23kV 25K 514 23 -60 2.2 112 115 42.2 439.400 454.700 10 23kV 25K 508 23 137 2.2 84.3 86.9 33.7 314.800 326.700 10 E No: None File Ref: 240-64 CP No.: CP9716 Rev. 02 Page: 6 of 9 TEMPERATURE RISE TESTS Requirements Backup current limiting fuses are required to carry all normal system steady state currents without incurring temperature rises that would be detrimental to any of the fuse parts. Objective The objective of this test is to verify that the temperature rise does not exceed the values specified in ANSI C37.47 and ANSI C37.40. Procedures Production fuses were tested per requirements specified in ANSI/IEEE C37.41 (Clause, 10). Current was supplied by a regulated current source. Temperature levels of the various current carrying parts were recorded throughout the duration of the test. Note that the fuse itself does not have a continuous current rating – there is an implied rating – that the fuse must carry about 1.5 times the rating of the cutout link it is used in series with – i.e. 60 A for the 40K fuse. Test Results Temperature rises were below maximum temperature rise levels allowed by standard IEEE C37.40-2003 Table 1. Conclusion The Companion II 12K – 40K fuses met the temperature rise requirements of Table 2 in ANSI/IEEE C37.40. E No: None File Ref: 240-64 CP No.: CP9716 Rev. 02 Page: 7 of 9 TIME CURRENT CHARACTERISTICS TESTS Requirements Time current characteristic curves are primarily for application selections and system coordination studies. These curves, minimum melt and maximum clear, detail the performance data of a particular fuse design. Objective Establish time current characteristic curves for the 12K – 40K Companion II fuses per ANSI/IEEE C37.47-1981 (R-1992) requirements. Procedure Testing was performed on production fuses which were assembled using established methods and procedures. Minimum melt and maximum clear time current characteristic curves were developed using ANSI/IEEE C37.41-2008, Clause, 12 requirements as a guideline. The curves reflect the typical industry tolerances ± 10% of the average melting current. An allowance for arcing time is also added to the total clearing curve to determine the fuse’s total clearing characteristics. Testing was performed at ambient temperatures. Results and Conclusions The minimum melt and maximum clear TCC curves for the 12 – 40K Companion II backup current limiting fuses were developed using the procedure described above and are detailed in R240-91-165. E No: None File Ref: 240-64 CP No.: CP9716 Rev. 02 Page: 8 of 9 RIV Testing Requirements RIV performance data for the Companion II fuse family is necessary in order to ensure proper performance of the fuse for the manner in which it is mounted in the field. Objective Determine RIV performance levels of the highest voltage and K-rated Companion II fuses; 17.2kV 40K, 23kV 12K and 23kV 25K. The highest rated fuses were chosen to represent the worst case condition; therefore this would represent successful performance of the entire Companion II fuse family. Procedure Testing was performed as detailed in ANSI C37.41-2008, Clause 8. Testing was conducted by mounting the fuse on top of a 27kV Type L cutout and was performed at 1 MHz. The fuses were secured to the cutout connector in the same manner as is typical field practice. An Electro-Metric meter, model EM-7535 S/N 144, was used to record the data. Results and Conclusions Fuse Part number FAH17KV40K FAH23KV12K FAH23KV25K Applied rms Voltage (kV) 15.8 15.8 15.8 Meter Reading (µVolts) <10 <10 <10 Corrected Reading (µVolts) <10 <10 <10 Barometer = 760.5 mmHg Dry Bulb = 23.5°C Wet Bulb = 16.5°C All fuses were less than the permissible maximum value, 250 µVolts, specified by standards. A 10 µVolt reading is considered RIV inception. E No: None File Ref: 240-64 CP No.: CP9716 Rev. 02 Page: 9 of 9 REVISION HISTORY Revision no. Date of addition/Change 02 6/3/10 Addition/Change made to report Updated report with new interruption data and RIV results Quality from Cooper Industries P.O. Box 1640, Waukesha, WI 53187