To Main Battery

advertisement

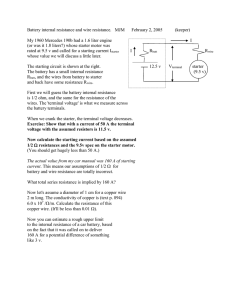

DISTRIBUTED BY: For Trailer mounted lift gate applications Model #11050C00 To Main Battery 75 * (refer to installation wire size table) 1. The Trail Charger should be mounted as close to the lift gate batteries as possible with the indicator light pointing out for easy visibility. Mount the Trail Charger in a dry, well ventilated area with no exposure to water spray, splash, runoff or immersion. Failure to do so may void warranty. Spray protective coating on terminals and connections. Glyptal 1202 red enamel insulating paint or similar recommended. Sure Power warranty does not cover corrosion related issues. If possible locate in battery box. Protect terminals from corrosion. 2. The power wires should be routed and supported following the manufacturers harness keeping all of the wiring protected. 3. Wire ties should be used to prevent wires from dangling. Keep slack to a minimum between wires exiting the trailer, wire channel and the Trail Charger mounting location. 4. Use grommets or dome nuts anywhere wires pass through holes cut in any type of material. Make sure wires are protected from abrasion. TractorTrailer Ignition Switch 75 amp fuse (Sure Part PN# 1595) Aux pin must be switched by tractor ignition switch To pin 7 of 7 way connector 75 Amp Fuse Trail Charger Connects to tractor battery 1 Main Battery 2 2 AWG or larger 3 4 Liftgate Switching Circuit Dual Pole Connector (refer to installation wire size table) TractorTrailer 180154B LITHO IN USA 02/09 Page 1 DISTRIBUTED BY: For Trailer mounted lift gate applications Model #11050C00 Indicator Light 75amp Fuse Installation Wire Size: (Proper installation requires a minimum run length of wire on the input terminal. Use no less than 10ft of 10AWG wire. Use 16 AWG for ignition wire and 2 AWG from output to liftgate battery. (Keep output wire length short) Input & Ground Wire Length 10 - 19 ft. 10 20 - 29 Ft. 30 - 39 Ft. 40 - 49 Ft. 50 - 59 Ft. ≥ 60 Ft. 8 6 4 Troubleshooting Standard size M8 Wire Gauge 1 2 3 1/4” quick connect terminal size 4 4 2 Indicator Light Term.1 Output Term.2 Input Term.3 GND Term.4 IGN To verify that the cables are all connected correctly and the unit is operating normally, we will make some voltage measurements. First on our list is the Input terminal relative to the ground terminal. With a commonly available voltmeter, connect the negative lead of the meter to terminal 3, the ground terminal. The negative lead will remain on terminal three throughout the remainder of the following tests. Now, connect the positive lead of the voltmeter to terminal 2. Observe the input voltage on the voltmeter and ensure it is reading greater than 11Vdc. Next is the Ignition, terminal 4. With the ignition switch on, verify the ignition terminal is reading positive battery potential, similar to what is seen on the Input terminal 2. Finally, we measure the output, terminal 1. The output voltage is normally higher than the input voltage. Typical output voltage at 25ºC is 14.2Vdc. Cold readings are typically higher and hot readings are typically lower. If the indicator light is on, that indicates current is now flowing through the output terminal. If the indicator is not on, that does not mean the unit is not functioning, it simply means no charge current is flowing on the output. If the load current on the liftgate battery is high, the LED may blink on and off periodically. This is normal. In any case, if the output, terminal 1 voltage is measured to be less than the input, terminal 2 voltage by greater than 0.1 Volts, it is normal to see this mode of operation, where the indicator blinks on and off. Whenever the ignition terminal is less than 7Vdc, you should expect the indicator to remain off. 180154B LITHO IN USA 02/09 Page 2