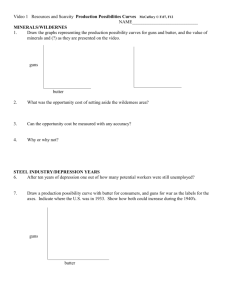

During Hay Feeding Season BUTTER MAKING "50-45-40" iWeihad

advertisement