Document 13698769

advertisement

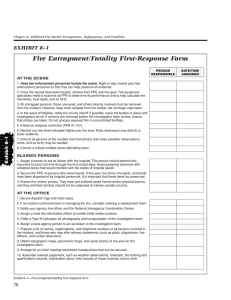

AMT – 111 Fire Protec/on Systems Chapter Fire Protec/on Systems • Fire is one of the most dangerous threats to an aircra= • Fire zones An area, or region, of an aircra= designed by the manufacturer to require fire detec/on and/or fire ex/nguishing equipment and a high degree of inherent fire resistance Loca/on – fixed or non-­‐fixed • Non-­‐fixed are serviced by hand held ex/nguishers • Examples: Fixed Fire Zones Engines and auxiliary power unit (APU) Cargo and baggage compartments Lavatories on transport aircra= Electronic bays Wheel wells Bleed air ducts • Serviced by fire detec/on and ex/nguisher systems Detec/on Systems • Most common: Overheat detectors Rate-­‐of-­‐temperature-­‐rise detectors Flame detectors Observa/on by crewmembers Detec/on Systems • Addi/onal op/ons: Radia/on sensing detectors Smoke detectors Overheat detectors Carbon monoxide detectors Combus/ble mixture detectors Op/cal detectors Classes of Fires • Class A -­‐ fires involving ordinary combus/ble materials, such as wood, cloth, paper, rubber, and plas/cs • Class B -­‐ fires involving flammable liquids, petroleum oils, greases, tars, oil-­‐based paints, lacquers, solvents, alcohols, and flammable gases Classes of Fires • Class Class C -­‐ Energized electrical equipment • Class D -­‐ fires involving combus/ble metals, such as magnesium, /tanium, zirconium, sodium, lithium, and potassium Detec/on & Protec/on Systems • Requirements: No false warnings under any flight or ground condi/on Rapid indica/on of a fire and accurate loca/on of the fire Accurate indica/on that a fire is out Indica/on that a fire has re-­‐ignited Con/nuous indica/on for dura/on of a fire Means for electrically tes/ng the detector system from the aircra= cockpit Detec/on & Protec/on Systems • Requirements: Resists damage from exposure to oil, water, vibra/on, extreme temperatures, or handling Light in weight and easily adaptable to any moun/ng posi/on Circuitry that operates directly from the aircra= power system without inverters Minimum electrical current requirements when not indica/ng a fire Cockpit light that illuminates, indica/ng the loca/on of the fire, and with an audible alarm system A separate detector system for each engine Fire/Overheat Detec/on Systems • Types: Thermal switch Thermocouple Con/nuous Loop Thermal Switch Thermal Switch Systems • Thermal switches are bimetallic switches • Thermal switches complete a circuit when they reach a cri/cal temperature • Mul/ple thermal switches are placed in parallel If any of the thermal switches reaches the cri/cal temperature, the alarm circuit is complete A failed switch will not take down the whole system • All the thermal switches are in series with the indicator light or circuit Thermocouple Systems Thermocouple Systems • Thermocouple system measure the rate of temperature rise A fast rise will indicate a fire Doesn’t use a cri/cal temperature • Thermocouple are polarized Hot junc/on Reference junc/on (cold temperature) • Thermocouples generate a small amount of current as they heat up Current must be amplified • Thermocouples are connected in series Con/nuous Loop Detec/on Systems • • • • Used in powerplant and wheel wells Superior detec/on and coverage Rugged Type: Thermistor • Kidde • Fenwal Pneuma/c • Lindberg Con/nuous Loop Detec/on Systems Fenwal System Fenwal System • Single wire system • Outer tube is conduc/ve • Tube filled with eutec/c salt Lowers resistance when tube gets hot Completes circuit between outer tube and internal wire Once the salt cools, the circuit is opened (reset) again • Can be connected in parallel for redundancy (protect against failures) Kidde System Kidde System • Similar to Fenwal but the electrical connec/ons are two internal wires (two d’s in Kidde) • Core is a thermistor core material More linear change to temperature changes than eutec/c salt Can double as a temperature sensor Can give separate indica/ons for overheat or fire condi/on Pneuma/c Con/nuous-­‐Loop Systems Pneuma/c Con/nuous-­‐Loop Systems • Lindberg Also called Systron-­‐Donner or Meggi^ Safety Systems • Heat causes the internal gases to expand and trip a pressure sensor Helium gas averages the temperature over the whole sensor Hydrogen gas is used to detect spot hea/ng When gases cool, the system resets Con/nuous-­‐Loop Systems • Physical damage to the tubes will damage them Dents, kinks, or crushed • Tubes come pre-­‐bent Don’t make your own bends • Damaged tubes can’t be repaired, they must be replaced • Class A zone Fire Zones Area of heavy airflow past regular arrangements of similarly shaped obstruc/ons. • Example: Power sec/on of a reciproca/ng engine • Class B zone Area of heavy airflow past aerodynamically clean obstruc/ons • Example: heat exchanger ducts & exhaust manifold shrouds • Areas where the inside of the enclosing cowling or other closure is smooth, free of pockets, and adequately drained so leaking flammables cannot puddle • Class C zone Fire Zones Area of low airflow past regular arrangements of similarly shaped obstruc/ons. • Example: Engine accessory compartment separated from the power sec/on • Class D zone Area of very li^le or no airflow • Examples: Wing compartments and wheel wells • Class X zone Area of heavy airflow and of unusual construc/on • Difficult to create uniform distribu/on of the ex/nguishing agent Smoke Detec/on Systems • Presence of smoke is an indica/on of fire • Used in lavatories plus cargo and baggage compartments Limited airflow Substan/al amount of smoke is generated before temperature changes are sufficient to actuate a heat detec/on system • Types (method of detec/on): Light Refrac/on Ioniza/on Smoke Detec/on Systems • Light Refrac/on Photoelectric cell that detects light refracted by smoke par/cles Uses a reference light source to “see smoke” • Ioniza/on Detects a change in ion density due to smoke in the cabin Carbon Monoxide Detectors • Colorless, odorless and tasteless gas Byproduct of incomplete combus/on Lighter than air The most common type of fatal air poisoning in many countries • Carbon monoxide detectors are used in areas with limited airflow such as cockpits or passenger compartments Carbon Monoxide Detectors • Chemical Detector Silica-­‐gel crystals that have been dyed with a yellow indicator dye Turns green when exposed to carbon monoxide Carbon Monoxide Detectors Carbon Monoxide Detectors • Chemical Detector Silica-­‐gel crystals that have been dyed with a yellow indicator dye Turns green when exposed to carbon monoxide Lasts 90 days and then must be replaced • Can also electrically detected and measure by: Biometric– A chemical reac/on that changes color like blood and measured electrically Electrochemical – reacts with sulfuric acid to generate electricity Sensors have limited life and must be replaced Ex/nguishers Ex/nguishers • Portable ex/nguishers Usually Halon or CO2 • Some/mes dry powder A commercial aircra= requires a least one portable ex/nguisher in the cockpit Aircra= carrying over 6 people will have a minimum portable ex/nguisher requirements Non-­‐metallic (plas/c horns) are required for an electrical fire FAA says dry-­‐powder ex/nguishers should be used on brake fires • Combus/ble metals are used in wheel and landing gears • Halon Ex/nguisher Agents Halogenated hydrocarbons Harms the earth’s ozone layer • Produc/on is banned Clean agent (no residue), electrically non-­‐conduc/ng and “rela/vely” low toxicity Halon 1301 – total flooding agent Halon 1211 – streaming agent • Halon Ex/nguisher Agents Other Halons too poisonous to use Should be recycled Being replaced with halocarbons HCFC Blend B, HFC-­‐227ea, HFC-­‐2 and HCL-­‐125 Used on Class A, B, & C fires • Not Class D – may react with burning metals Most common agent used in ex/nguishing systems (non-­‐portable) • CO2 Ex/nguisher Agents Carbon dioxide • Two oxygen atoms 1 ½ /mes heavier than air • Drops to the base of the fire and smothers the fire by displacing the oxygen Cools the fire Mildly toxic Used on Class A, B, & C fires Clean • Good for small engine fires • Water Ex/nguisher Agents Smothers and cools fire Prevents re-­‐igni/on Used on Class A fires • Dry Power Messy Class of fire varies with chemicals used in powder • Check label Specialized dry powder can be used on Class D powders Ex/nguishing Systems • Components: Agent Containers Discharge Valves Pressure Indicators Two-­‐way Check Vales Thermal Discharge Indicator (Red Disk) Yellow Disk Discharge Indicator Fire Switch (ac/va/on switches) Ex/nguishing System Agent Container Ex/nguishing Systems • Agent Containers Stores fire ex/nguishing agent Usually pressurized with nitrogen Has an over pressure release • Discharge Valves An explosive charge (squib) is electrically detonated The explosion breaks a frangible disc that releases the ex/nguishing agent • Pressure Indicators Indicates the status of the containers load Ex/nguishing Systems • Two-­‐Way Check Valves Directs agent to the correct loca/on • Thermal Discharge Indicator (Red Disk) Broken/missing red disk indicates the container has released agent due to overpressure Container must be serviced • Yellow Disk Discharge Indicator Missing yellow disk indicates the agent has been used Container must be serviced Ex/nguishing Systems • Fire Switch (ac/va/on switches) Releases the agent Ex/nguishing System Maintenance • Regular inspec/ons are required • Portable ex/nguishers are checked by weight or pressure check • Discharge valve squib must be handled with care Ground/short the terminals when working with the squib • Prevents accidental discharge Insure no voltage is present on squib trigger leads when installing squib Squib and valve may be a matched set and must be replaced as a set Ex/nguishing System Maintenance • Ex/nguishing systems are check by pressure Acceptable pressure range will vary by temperature Containers out of range must be serviced Ex/nguishing Pressure Chart Ex/nguishing Pressure Chart € Ex/nguisher Pressure Problem • FAA problem requires interpola/ng a chart • Perform the following equa/on for both the Minimum and Maximum column to determine the range Temp = SmallTemp + (L argeTemp − SmallTemp) X (Given Pr es − SmallPr es) (L argePr es − SmallPr es) Ex/nguishing System • Reminder: Aircra= plumbing that contains fire-­‐ ex/nguishing agents is color coded with a stripe of brown tape and a series of diamonds.