Starter Cable Upgrades

advertisement

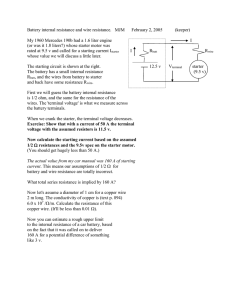

Product Issues Starter Cable Upgrades We previously touched on cable upgrades. l-Iere is a more comprehensive look at cables and other available upgrades. BY LPM STAFF nyone reading LPM for a while knows that we write a lot about electrical issues such as basic wiring, batteries, starters, alternators and the like. One big reason is that reader e-mail is constantly asking for advice on chronic failures of these parts, systems, and if there are any products available that may improve reliability and/or performance. Hint-there are. One cause of aircraft problems is that everything is done with an eye on minimal weight. This has resulted in marginal sized starting batteries and often low powered starter designs subject to relatively easy overheating or overuse. While the availability of lightweight starters has helped the weight issue, it has placed increasing demands on starter cables and components. With such expensive aircraft component costs we sometimes see owners waiting until a part fails before replacement. In some cases, owners are doing it with a cheaper, non-aviation qualified replacement part-a potentially dangerous idea. A failing part often dies gradually, which sometimes causes related system malfunctions, "intermittents" and general performance degradation while failing. Contributing to this is sometimes a lack of comprehensive, ongoing preventative maintenance or routine parts replacements, particularly in areas that may not be readily accessible for inspection. This is also related to some owner efforts at keeping maintenance costs to a bare minimum, an understandable but often futile goal for aircraft safety. This strategy frequently ends up costing much more than good preventative maintenance. Dealing with part failures is certainly more inconvenient than planned maintenance. A got these photos recently while a Piper Cherokee was in for an annual at a local shop. It was a fortuitous time as it illustrated several common problems, both with the battery box setup and with wiring practices. In our observations this plane needs additional repair of this system to pass the annual and to be safe and to start reliably. The owner was not available for an interview. (See photos.) What we have is a battery box of the old Piper style that had the stock undersized aluminum cables replaced between the starter motor attached to the engine and the battery relay beside the battery box. He also replaced the cables from the relay to the battery box with copper. Unfortunately, there are still existing problem issues with the stock setup on the positive terminal on the side of the battery box, as well as the alterations done to the negative terminal cable. The positive cable from the battery relay connects to a lug on the side of the battery box. In turn, this connects to the battery via the soldered braid to the battery terminal. This adds an unnecessary additional terminal connection at the outside of the battery box. It also tends to reduce starter current available to the starter motor by design if the connections are in anything but ultra pristine condition. Especially with high current applications you do not want to have any more terminals or connections than absolutely necessary. The original design was more complicated than it needed to be for reliability and adequate starting power between the battery and starter motor. Cable size was marginal. In this airplane there has been an attempt to add aftermarket cables made of copper-a good idea with not such good execution. We were not able to assess the cables between the starter motor and the battery relay so we will concentrate on the battery box wiring, and there is plenty to address here. The negative cable was pushed through a small hole cut in the side of the battery box. The hole is so small, it almost appears that the terminal was crimped on after the fact, but in any event the terminal was crimped with a lower quality, small cross section crimper, as opposed to being attached with a professional grade tool. This results in less optimal crimped surface area and greater potential for the infusion of corrosive agents into the terminal. Further promoting corrosion in an acidic environment is the lack of any heat shrink protective wrap on the terminal-tocable junction. The net result is reduced current capacity over what could have been possible and substantially increased exposure to corroOld-style Piper battery box originally had aluminum cables to starter. The factory later recommended upgrading to (opper, but specified undersized cables. There are two sets of cables involved. Those from the relay to the starter motor and a separate set from the relay to the battery box or battery. There are better options for reliable starting and safety. ASPECIFIC WMPlE Let's look at how one Piper owner has tried to solve his starting cable issues. We www.lightplane-maintenance.com APRIl2014 . . CABLE SPECIFICS Photo is reversed 180 degrees for a better visual appearance. Note messy braided cable inside box, which adds an extra connector. Replacement copper negative cable wire was run through the side of the ragged hole in side of box with no cable protection from chaffing. sian by-products further reducing current capacity. The circuit is no more reliable than the weakest link. More problems exist here as well. The wire was run through the side of the box with no protective grommet or any form of protection from chaffing on the side of the ragged hole in the box. Accepted shop practices require grommets!chaffing protection for all wiring. This suggests amateur, unapproved work. While it may be argued this is only a ground, as the chaffing progresses the increasing number of cut strands will re- duce the whole electrical system effectiveness. Eventually the plane will not start or other high current devices will not operate properly. The ground wire capacity needs to be the same as the positive wires for the system to work properly. Ifthe ground wire is chaffed and strands are cut, the system is compromised. Even more significant is this hole without a grommet will not keep acidic battery box air from infuSing into the fuselage. Notwithstanding the existence of a functional vent line, this is still a danger- Negative cable was crimped with so-so crimper. The entire terminal would greatly benefit in performance from pro-quality crimp of this critical, high current connection. There is no protective plastic shrink wrap to keep out the battery fumes that will accelerate corrosion into the terminal connection-read early failure. The un-grommeted hole in the box allows add fumes into the fuselage. The braided terminal is also showing signs of fraying as it is folded at an angle by design. . . APRIL2014 The aluminum found in most Piper aircraft (AL-l) was designed to max out at 180 amps. The 4-gauge copper cable Piper suggested as the replacement in 1986 in their S.B. 836 is rated at 135 amps. Though the same physical weight as AL-1, it does not have nearly enough current carrying capacity for the average system. Bogert's Low Loss Cables are rated at 211 amps. This means that Bogert's cables have 50 percent more capacity than 4-gauge copper and 25 percent more than the original AL-1. Agood way to check if you're getting adequate voltage to the starter is to use a voltmeter on the starter while cranking. (Watch that prop and set the meter up to do the check remotely with the "voltage hold" function.) Afully charged battery (12-volt system) that drops to less than 10 volts at the starter when cranking indicates that the starter(s) may not be getting enough voltage. Low voltage equals slow cranking speed. Slow cranking speed equals high current flow and heat buildup in the entire system. The high current draw at low voltage will reduce the battery and starter life, as well as increase the chances for a fire. As the voltage drops the current goes up to try to feed the high current needs of the starter motor, until the voltage drops to a point that either the relays will not operate or the starter motor will not tum. Unfortunately, since the starter is designed to operate down to 9.6 volts or so in a 12-volt system there is a built in ability for the starter system to overheat with prolonged cranking if the pilot is not aware of this potential. (Cranking time limits are given with starter motors and are based on adequate wiring and a good battery.) When the battery is low or the cables have more resistance than they should from age or corrosion or being undersized it aggravates an already serious safety problem. Aspecial note to pilots with lightweight starters: They can be very useful when carefully selected for the application. In our view, we would go for the high-end units for anything other than very occasional use, as there is a significant range of quality available. Lightweight starters are power hungry,and need high inrush voltage to operate correctly compared to a standard starter. Please make sure your battery is in top condition, or you may have problems. That means using wire that is large enough and in great condition. If you're . not willing to make the investment for the best cables, don't bother with a lightweight starter in our opinion-it won't live up to its potential. LIGHT PLANE MAINTENANCE ous practice. Note that flight control cables run near the box. AUTOMOTIVE ROOTS Some components simply do not hold up as well as hoped in the tasks they were asked to perform as they have been adopted from other industries (read cost savings) rather than purpose built Earlier switch gear was adopted from the automotive industry as were voltage regulators and generators/alternators. This same principle holds for other component classes. Early failures generated some part modifications by the aircraft manufacturers. Over the years there has been some evolution for greater ruggedness and reliability, but many electrical components still have their roots in automotive technology with attendant shorter life spans. Today these components, when qualified for aviation, are supposed to be quality controlled more rigidly and altered/improved to meet aeronautical! PMA quality standards for reliability under more demanding conditions. Some products seem to do pretty well without any mods. All they need is the extra quality control checks. Others need more substantial beefing up in addition to the individual quality checks. For example, while your modern aeronautical alternator looks virtually identical to an automotive version from the auto parts store, it often has been subtly modified for more severe duty and reliability. All the above said, there are many people who believe there is absolutely no difference between a Chrysler alternator from the auto parts store or from an aero parts retailer. We disagree. Legally the point is moot, since it's illegal to put a non-PMA part on a certified airplane. (Some small components are not offiCially stamped PMA but are expected to meet MIL or SAE or other civilian industrial standards of accepted quality such as nuts and bolts and terminals according to the FARs.) ALUMINUM WIRE FAILINGS Sometimes there is simply a bad choice made with good intentions to save weight and cut costs. An example is aluminum starter cables used in some older Piper aircraft. The aluminum may have looked OK on paper but just never properly did the job. www.lightplane-maintenance.com Because of the metal mismatch and 25 percent under-sizing for amp needs, there were accelerated corrosion issues and starting problems-even fires in some instances from overheating wires and battery box connections. There were subsequent Piper service bulletins recommending replacing the cables but there are aluminum starter cables or battery box terminals that still exist (see sidebar for problems even with copper cables recommended by the factory). Fortunately; there have been some independent companies who have made it their goal to dramatically improve some of these sub-performing components with a more robust and effective products. Bogert Aviation is one example of a company that developed improved copper starter and battery box connector cables, and over the years has developed other improved products over OEM deSigns that fill an important niche. They provide both electrical performance improvements as well as added safety with their electrical products. They are all STC'd or otherwise qualified for certified aircraft where required. Their available wiring products continue to expand since there is a growing demand, including for experimental aircraft. Contact them for custom wiring needs. Bogert Aircraft also has an eclectic mix of jacks and associated products as well as fuselage and wing restoration rotators. For a more complete set of products go to Upper left, old style Piper battery box terminal and Bogert replacement. left, Replacement Bogert battery box eliminates extra conne(tions. Above, top, dose up of Bogert STC battery box modification. Above, Bogert has a selection of custom (abies as well as a number of other electrically oriented and eclectic products. www.bogert-av.com.com. phone (800) 627-8088. OUR FAVORITE REPLACEMENT Our favorite Bogert STC'd products are the improved starting cables for Pipers that had the aluminum cables. The complementary product to the starter cables for the Piper is the battery box modification to replace the complicated, trouble prone, OEM design. They also have the short cables from the relay to the battery available in high capacity copper. This STC'd battery box mod makes for easier battery installation/removal and eliIninates the extra connection on the outside of the battery box. It also does away with the troublesome braided battery box strap, redUCing system complexity. (See photos.) This mod is less expensive than to replace the entire battery box. However, a complete STC'd Bogert battery box incorporating all the mods is also available. Note that aircraft using Concord CB35A and RG-35A batteries must install two PN 1-1-6 adapter plates to the battery posts before completing the Battery Box Modification. These adapter plates raise APRIl1014 . . (Continued from Previous Page) the battery post height to equal the post height of standard G-35 series batteries. Bogert also sells improved starting cables available for many other GA aircraft. The benefit is improved starting current flow from low loss cables and properly attached and protected terminals. Wire and terminals need periodic replaCing as age and heat and high current does take a toll. We've seen very old starter cables fall apart as we started to detach them. This can help improve starter and associated relay!contactor life by reducing heat and improve battery life by reducing incidents of severe battery drain to overcome higher resistance OEM cables. It can also help provide a start with a depleted or partially discharged battery where an OEM cable would not do it, all other things being equal. These cables make a great upgrade for any airplane, especially older Pipers. One last note, though-replacing a starting cable in an airplane can prove to be a real exercise in gymnastics and frustration. The wires can be very difficult to access and replace. Get a mechanic's supervision. A few of the aviation catalogs sell the Bogert products or go to their Web site at bogertaviation.com, ph (800) 627-8088. HEAVY CRIMPERS We might note that we have seen (and tested) several very marginal, low cost cable crimping devices for heavy gauge cable for sale in aero catalogs. Some crimpers are hit with a hammer; others use a small crimping surface. In our opinion, testing and experience, while these devices can be made to work, they will absolutely not give the full performance that your high current cable was designed to carry. They become the weakest link as well as the subject of much easier ingress of corrosion-even with a protective wrap. Aproper set of heavy duty cable crimpers have huge handles; some are hydraulically assisted, and will cost several hundred dollars. The advantage is they crimp most of the terminal surface to, in essence, form a cold weld. Have your cables properly fabricated by a professional shop. The result will be years of optimal use and your battery will be able to deliver the power your starter or other high current devices needs to work optimally.· . . APRIL2014 Tuned Exhausts Like any speed/pelformance mod) understanding benefitsand costs- is the best way to decide if it suits your needs. BY LPM STAFF hat are tuned exhausts? Many owners are probably familiar with the term "headers" with respect to the automotive world. Headers are commonly referred to as an aftermarket, owner purchased replacement part for the exhaust system that bolts directly to your engine exhaust ports. With due deference to possible oversimplification, the primary use for tuned headers is for increased engine power and efficiency. The idea is to optimize the pipe length, and diameter and to minimize restrictions in the exhaust header for performance increases over stock systems. Usually high rpm is where the most benefit is seen with tuned exhausts. The engineers at Power Flow describe a stock exhaust system operation as follows : ''As the spent fuel air mix ture leaves the cy linder, it is routed through a set of headers into a common collector area and pushed out the tail pipe by the remaining pressure. Like a garden hose with a kink in it, (referring to a stock system) pressure builds up throughout the exhaust system, making it more difficult for the spent gas mixture from the next cy cle to leave. So now, the exhaust isn't flowing as freely as it should, leaving some exhaust in the cylinder, taking up space better used for a clean fu el/air charge." "Our Power Flow Tun ed Exhaust System is totally different. When you break down our exhaust system, you have two "sets" of pipes; the primary (header!collector combination) and the secondary (pipe after the collector). The primary contains four independent tubes that all join at the ''4-1 Collector. " As each "exhaust puff" of spent fuel travels through the prima- W ries, it leaves a vacuum behind." "In our tuned exhaust system, we have adjusted the length of each tube so that the vacuum reaches the collector just in time to "suck out" the exhaust from the next cylinder. The exhaust gases are not only being pushed out by the cylinder, but "extracted" by the vacuum, so a bigger, fresher charge will enter the cylinder during the next cycle. A tuned exhaust system really promotes a smoother, cooler, and more powerful running engine. " At LPM we agree with this assessment; it's only the degree to which such a system is effective at lower rpm increases that may be debatable, considering the limited RPM range of an aircraft engine and space we are dealing with in an aircraft engine and the engine compartment. HOW WELL DO THEY WORK? If our airplane engines were higher revving beasts the effects of tuned headers would be more dramatic as they are in high revving auto race engines. As it is, there is still a measurable benefit. But these systems are not cheap, and if payback from fuel effiCiency is your goal it probably may never happen, since header wear and tear (as with any stock system) will take its toll long before the payback time is reached via fuel savings. What are the claims? Well, they vary from airplane to airplane, but a minimum of few hundred feet per minute and 2 knots or even more should be expected for a, say, a Cessna 172. (Power Flow claims up to 6.5 knots in fixed-pitch prop engines to correspond to the typical 30 to 130 RPM increase.) They also claim a 1.19 to 1.9 GPH or even better fuel improvement is possible. For some constant-speed props LIGHT PLANE MAINTENANCE