White Paper WP525001EN

Effective March 2015

Achieving energy efficiency through

integrated lighting controls

Michael Lunn,

Senior Product

Manager,

North America,

Eaton’s Cooper

Lighting Division

Table of contents

Description

Page

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Know control: turn on to smarter, more versatile lighting control options . . . . . . . . . . . . . . . . . . . . . . . . . .

Code compliant construction: the new mandate for energy efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Great expectations: lighting power density and control requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discover COI (Control Over Investment): save energy and money with

integrated lighting control solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conclusion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Highlighted resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Eaton. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

2

2

4

4

5

5

6

6

Introduction

With reports from the U.S. Energy Information

Administration indicating that “21 percent of the

total energy used in commercial buildings and 38

percent of all electricity used in commercial buildings is used for artificial lighting” (Gelfo, 2013), it’s

no wonder that recent building codes have given

automated lighting controls the spotlight.

A 2013 Navigant Research Report suggests that

“worldwide revenue from networked lighting

controls will grow from $1.7 billion annually in

2013 to more than $5.3 billion by 2020.” Of this

figure, the forecast finds revenue from occupancy

sensors, photosensors and lighting network

control gear alone could reach nearly $2.7 billion.

Of the approximately 3,684 terawatt-hours (TWh)

of electricity produced in the United States

annually, about 18 percent (or 700 TWh) is

used for lighting. Up to 92 percent of lumens

(total light emitted) used are taken up by

non-residential settings.

“As falling prices for light emitting diodes (LEDs)

drive up adoption rates of LED lamps, the adoption

of lighting controls will also accelerate” (Navigant

Research, 2013). Increasingly, more stringent code

compliance requirements and a growing interest

in lighting design versatility are key factors driving

this demand.

Lighting affords one of the simplest means to both

conserving energy and reducing carbon dioxide

(CO2) emissions (Kay, 2012). With intelligent lighting control systems, we “can [further] reduce

the amount of energy waste[d] from lighting”

(Rubinstein, 2011). Today’s lighting control systems

can provide real-time information on energy

utilization or send alerts when events occur or

problems are detected. Significant resource gains,

cost savings, design flexibility and user benefits

are possible.

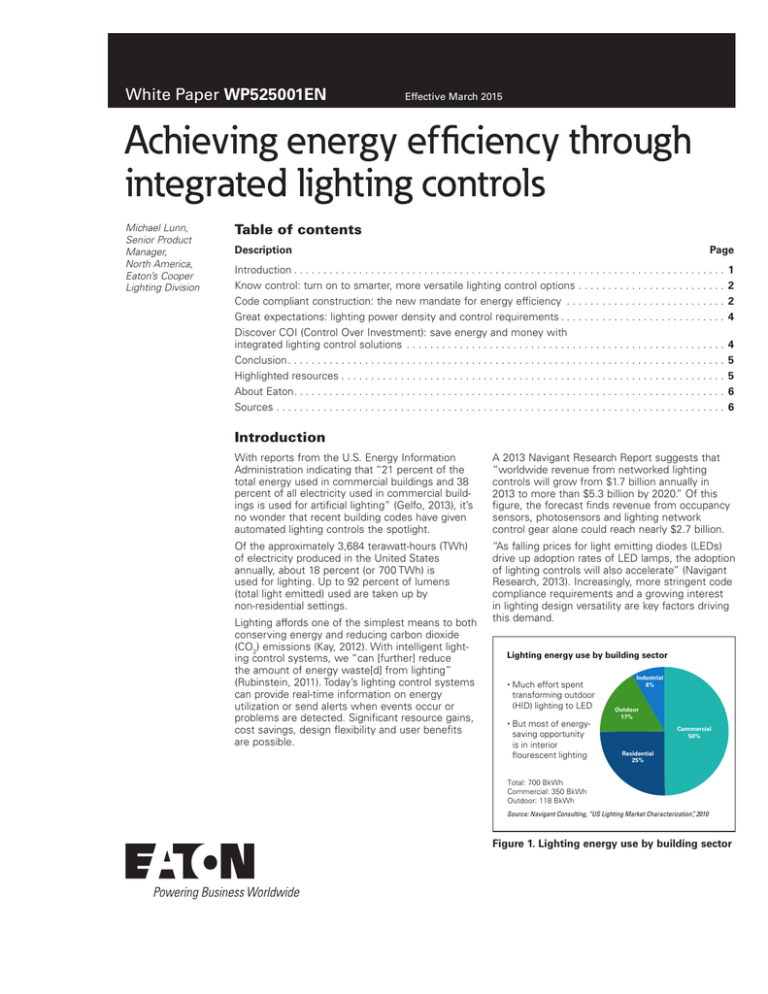

Lighting energy use by building sector

•

Much effort spent

transforming outdoor

(HID) lighting to LED

•

But most of energysaving opportunity

is in interior

flourescent lighting

Industrial

8%

Outdoor

17%

Commercial

50%

Residential

25%

Total: 700 BkWh

Commercial: 350 BkWh

Outdoor: 118 BkWh

Source: Navigant Consulting, “US Lighting Market Characterization”, 2010

Figure 1. Lighting energy use by building sector

White Paper WP525001EN

Achieving energy efficiency through

integrated lighting controls

Effective March 2015

Know control: turn on to smarter, more

versatile lighting control options

Almost everyone is familiar with the dimming switch. Early efforts

to control lighting allowed an individual user the ability to directly

control available light in a specific environment. Other basic controls

include manual, personal and room control.

A second set of options emerged with the introduction of sensors

to the space. Motion sensors detect whether or not a user is

present and illumination is needed. Programmable controls such

as occupancy sensing vacancy sensing and auto shutoff rely on

motion-based sensing to turn lights on or off as needed.

With the addition of integrated controls and tuning, lighting automation affords powerful energy savings and exciting design solutions.

With these controls, sensors are integrated directly within the fixture

or luminaire. This makes it possible to gauge energy and lumens

output with precision, while controlling specific fixtures individually.

Integrated controls also allow several different control strategies

to work in unison—for example, occupancy sensing, daylight

harvesting and personal dimming might all be employed at once

to achieve optimal efficiency.

In September 2012, the General Services Administration (GSA)

reported on the energy savings potential of occupancy response

control. The evaluation focused on three control strategies: personal

controls, occupancy sensing and institutional tuning and scheduling.

The study spanned seven locations across five buildings with

different occupancy and work style patterns. Results showed

energy savings that ranged from 27 to 63 percent with payback for

continually used spaces achievable in less than 7 years (GSA, 2012).

Spaces with long operating hours and varying occupancy patterns

benefited most.

Even more recently, the GSA released findings from a study of

Integrated Daylighting Systems (IDS). Daylight harvesting is the use

of daylight to help offset energy consumption from artificial lighting.

“IDS measures prevailing natural light against predetermined

lighting setpoints and signals electronic dimming ballasts to

minimize electric light output accordingly”(GSA, 2014). The study

estimates potential energy savings from IDS—where daylight

harvesting is one of several components in a well-integrated

lighting control system—to be as high as 60 percent.

A range of other lighting controls address more detailed aspects of

the holistic lighting infrastructure, including multi-building control

and monitoring, receptacle control, zoning and emergency controls.

Renowned lighting expert Francis Rubinstein provides a thorough

overview of the differences and nuances of available options in

Lighting Controls in Commercial Buildings.

Table 1. Potential energy savings from integrated lighting controls

Annual lighting cost savings

Occupancy

sensing

scenario

Percentage

U.S. dollars

Size

(sq ft)

LPD

(watt/sq ft) a

Lighting

hours

Commercial

electricity

cost

(cents/kWh) b

Restroom

60%

$101

300

0.98

5,600

Private office

45%

$27

150

1.1

Corridor

35%

$48

450

Warehouse

75%

$152

Standard classroom

40%

$170

Without

occupancy

sensors

With

occupancy

sensors

10.2

$168

$67

3,500

10.2

$59

$32

0.66

4,500

10.2

$136

$88

1,000

0.66

3,000

10.2

$202

$50

1,200

1.24

2,800

10.2

$425

$255

a These are the lighting power densities (LPD) allowed by space or whole building per ASHRAE 90.1-2010.

b This was the average kWh cost in the U.S. in 2011 as reported by the Energy Information Administration.

2

EATON www.eaton.com

Annual lighting cost

(U.S. dollars)

Achieving energy efficiency through

integrated lighting controls

Code compliant construction: the new

mandate for energy efficiency

Every builder should consider an integrated lighting controls strategy

early on in new construction or retrofit projects.

Each state within the United States currently requires some

version of the American Society of Heating, Refrigerating and

Air-Conditioning Engineers’ ASHRAE 90.1 building standard. An

October 2013 ruling by the Department of Energy (DOE) mandated

commercial compliance with the minimum requirements set forth in

ASHRAE 90.1-2010. All jurisdictions in the U.S. will soon be required

to comply with it or a superior state energy code. California’s Title 24

is perhaps the most stringent of all state codes; it went into effect

on July 1, 2014.

ASHRAE 90.1-2010 introduces the greatest leaps in lighting controls

requirements in some time. All new construction and retrofit projects

with greater than 10 percent of the connected lighting load modified

must comply with the new ASHRAE 90.1-2010 requirements or a

stricter code. This means that even small lighting upgrade projects

may need to meet code compliance. Significant changes include

stronger lighting control requirements tied to specific lighting control

applications and stricter lighting power density (LPD) values.

Automatic shutoff is prominent in the ASHRAE 90.1-2010 code and

requires methods to achieve automatic shutoff in most spaces.

Typically, shutoff must occur within 30 minutes of vacancy. “At least

one control device (e.g., light switch, dimmer, or occupancy sensor)

is required for each space enclosed by ceiling-height partitions to

control that space’s general lighting” (Schultz and Chow, 2011).

Prior to this code update, around half of the energy used by a lighting

system was consumed while portions of the facility were vacant.

Occupancy sensing and time scheduling systems eliminate wasted

energy by minimizing the operating hours of the lighting system

while accommodating the variable work hours and habits of the

building’s occupants.

Daylighting strategies are also given emphasis in the updated code.

Mandatory control provisions are set for spaces with primary and

secondary sidelighting (large windows) and/or toplighting (skylights).

Many of the code changes address specific control of task-oriented

spaces. A combination of auto shutoff and daylighting may be

required for employee lunch and break rooms; conference and

meeting rooms; classrooms, lecture halls and training rooms;

storage or supply rooms of 50 to 1,000 square feet; copy and print

rooms; office spaces up to 250 square feet; restrooms; and dressing, locker or fitting rooms. Additional requirements are defined for

parking lots and garages.

Commissioning is required by ASHRAE 90.1-2010, which ensures

correct installation, testing and maintained usage. It’s clear that

this requirement is a result of both the increasing capabilities

and complexity of lighting control options, as well as the higher

mandates for achieving energy efficiency in the commercial sector.

“If the controls [and their intent] are not well-understood or do not

function properly once a building is ‘turned over’ or the renovated

areas are occupied, there is little chance the projected energy

savings can be realized“ (Allen, 2014).

Rubinstein points out that luminaires that incorporate integrated

sensors avoid many of the potential commissioning issues faced

when using area-based sensors. Look for products that feature

factory-installed sensing systems such as the Metalux EncounterE

with integrated sensors from Eaton.

White Paper WP525001EN

Effective March 2015

Addressable control systems reduce the amount of line voltage

wiring on a project by 50–80 percent as compared to a relay-based

solution. This is because control shifts from circuit level (relays) to

individual devices (addressable) greatly simplifying the electrical

design and the wiring installation.

Digital addressable controls offer two distinct advantages:

1.) Each ballast/driver has a unique ID (address); and 2.) all of a

facility’s fixtures can be networked together. As a two-conductor

data wire-based solution, digital addressable control systems

enable a simple enterprise-level solution that a building manager

can program, manage and maintain for best-in-class energy

management capabilities.

Addressable controls may be either wired or wireless. Although

both can be used within a facility, addressable wireless controls

are especially common for outdoor applications.

Previously, addressable controls dealt only with large zones where

a relay might control 20 amps or 10 fixtures at once. With the new

digital addressable controls, however, the fixture itself is smart.

Controls can “address” a specific driver or even an individual fixture

for illumination or power adjustments, maintenance and reporting.

Software-based addressable control allows for fully personalized

lighting ergonomics. Multiple points of access allow end users

to interact with the lighting system in the most convenient way

possible: whether by wall stations, web-based software, VOIP

telephones or mobile devices. Addressable systems such as Eaton’s

Fifth Light System allow for intelligent lighting control via either a

mobile device or a centralized dashboard software solution.

Remote controls borrow the paradigm of anywhere, anytime control

using mobile devices and software. Today’s users are accustomed to

home security systems with remote control access via mobile apps;

the same functionality is expected in all aspects of the workplace.

With this approach, wall stations may not be needed at all; using a

combination of occupancy sensors and a mobile device, a user can

control the lights while approaching the building.

App-based controls also integrate easily with an iPadT or mini tablets

that can mount to the wall for in-room or complementary control

needs. This approach makes it easy for updates to be made to

the control interface at any time, significantly improving the user

experience on an ongoing basis.

For facility managers, a user-friendly, enterprise-wide view of all

the lighting, power and energy use in their building (or buildings)

is critical for effective operations. Many different software packages

are available with a range of automation features to support

maintenance, reporting and analytics.

By running automatic system checks and then delivering a detailed

status report, Eaton’s Fifth Light System keeps maintenance crews

in the loop via automatic email notifications. The monitoring system

can detect luminaire tube and ballast or driver failures and provide

detailed system diagnostic reports.

More importantly, the Fifth Light reporting software allows building

managers to view, track and chart the energy consumption of their

lighting system on a user-by-user, floor-by-floor and tenant-by-tenant

basis. All the lighting and power being used in the building—down to

control of a specific fixture or group of fixtures—can be monitored

and maintained quickly and easily from a single dashboard.

To achieve optimal energy efficiency while securing code compliance, consider lighting controls that integrate addressable systems

with software control available from multiple devices and touch

screens. For the commercial sector, this approach introduces basic

lighting intelligence and intuitive design elements that can result in

significant energy savings.

EATON www.eaton.com

3

White Paper WP525001EN

Achieving energy efficiency through

integrated lighting controls

Effective March 2015

Great expectations: lighting power density

and control requirements

ASHRAE 90.1-2010 has set new expectations for controls requirements in energy codes moving forward. For example, the code may

require controls for only turning lighting on to 50 percent power or

less by default within a designated space. In these scenarios, an

“occupant needs to manually flip the switch to energize the remaining

lights, thereby illuminating the space 100 percent” (Allen, 2014).

Prepackaged lighting control systems are a simple and easy way to

achieve the necessary offset in LPD required for code compliance.

In some states, tax credits are incentivizing the commercial sector

toward implementing controls for higher LPD offsets. There are

specific incentives for demand response under Title 24 (see details

in DiLouie, 2014). The federal Energy Policy Act of 2005 (EPAct05)

features similar incentives specific to lighting retrofits. Available

incentives on a state-by-state basis can be found by visiting

http://www.dsireusa.org (Chow, 2014).

Discover COI (Control Over Investment):

save energy and money with integrated

lighting control solutions

Recent implementations at the local, state and national levels

demonstrate increased savings, improved efficiency and faster

return on investment from new construction and retrofit projects

employing integrated LED-based lighting control systems.

“LED retrofits can save 40 percent or more energy when compared

with traditional light sources such as incandescent, halogen, and

high intensity discharge (HID)” (Chow, 2014). By adding integrated

controls to the LED lighting mix, it’s possible to gain smarter control

in each room along with maximum lighting flexibility for individual

tasks or specific user preferences. Each light fixture can be individually controlled so that two people sitting side by side can both have

their unique preferences met at the same time.

Integrated LED control solutions can also better address energy

use and lighting design aesthetics in spaces that were previously

extremely difficult to light efficiently. Large or awkward spaces

benefit from a mix of integrated controls, tuning and fixture grouping

schemes. Rubinstein offers an example of fixtures bundled into large

zones that can be programmed to operate in concert with occupancy

sensors and addressable wireless controls: “When any fixture in the

group senses occupants, all fixtures in the group turn on to a ‘background’ lumens level; the fixtures above specific occupants can then

manually or automatically brighten to a higher level” (Rubinstein,

2014). Areas where major energy efficiency gains can be seen from

this approach include high bay lighting; outdoor and site lighting; and

some specialty lighting applications such as patient lighting.

The Sustainability Club at the National Science Foundation (NSF)

Smart Lighting Engineering Research Center (ERC) demonstrated a

major luminaire replacement project on the campus of Rensselaer

Polytechnic Institute. More than 300 par 30 halogen luminaires

operating 24/7 were replaced with LED fixtures in the Great Hall and

Darrin Communication Center (DCC). The halogen lights consumed

an estimated 200,000 kilowatt-hours per year, costing the campus

about $13,000 in energy costs alone. With an estimated lifetime

of only 3,000 hours, these luminaires were constantly in need of

replacement, a time-consuming process that required a ladder and

two employees.

Initial energy savings projected at 80 percent allow for a return on

investment within just 18 months and significant energy savings

annually. The largely student-led project in the DCC alone will realize

an estimated $21,000 per year in energy and labor costs savings as

well as a reduction in Rensselaer’s annual carbon footprint by 123

metric tons of CO2.

4

EATON www.eaton.com

With many new construction and renovation projects ongoing or in

the planning stages, Washington State University (WSU) sought a

lighting control system capable of meeting both new building codes

and retrofit requirements across a diversity of space functions and

task-based applications. WSU’s campus comprises more than 630

buildings; the school’s example projects included interior and exterior

renovations of Martin Stadium, design of a new residence hall and

installations at recently completed research laboratory facilities such

as the Veterinary and Biomedical Research building.

WSU’s presiding concern was auto shutoff control to satisfy building codes and minimize energy waste. Eaton’s Greengate lighting

control system was chosen for its impressive customization capabilities and for its ability to support goals and requirements for LEEDT

certification.

As an energy management solution, Greengate accommodated the

specific needs of a wide variety of spaces requiring the same key

lighting control components—the Greengate lighting control panel,

occupancy sensor and photosensor. “We combine the timeclock

control from the lighting control panel and occupancy sensors to

execute the full sweep off, required by Washington building codes,

without leaving people in the dark,” said Brian Funke, construction

manager for WSU.

Measured lighting energy use at 12 demonstration sites

before and after installation of lighting controls

Annual lighting energy use intensity (kWh/square foot/year)

8

Pre-retrofit

6.50

Post-retrofit

6

4.71

National office average EUI (4.5 kWh/sf/yr)

3.74

4

2.23

2

2.36

2.52

2.52

2.72

2.75

2.92

1.80

2.52

2.17

1.70

1.31

1.66

1.34

1.47

LG2N

FI A

2.34

2.21

M3NW

R18

1.79

0.84

0

2.92

RD13N PB10W CW2NE RD14S RD8N

1.09

CH2SE LG5S

FI B

Lighting controls demonstration site

Figure 2. Energy savings from lighting controls at

12 demonstration sites (source: Rubinstein Lightfair

2014 presentation)

LEDs are a higher efficacy light source. By offering more lumens per

watt per square foot, LEDs reduce overall lighting power consumption

while vastly improving illumination design flexibility and aesthetics.

Chow (2014) outlines several other reasons why LEDs have become

attractive: low environmental impact from a combination of energy

savings, longevity and a lack of hazardous materials; no UV (ultraviolet) rays or IR (infrared) heat radiation; ideal for frequent on–off switch

cycling common in meeting requirements for occupancy sensors;

LEDs have instant full-on output such that no warm-up is required;

and they lower life cycle costs both in efficiency and longevity.

At the 2014 Lightfair, Rubinstein summarized preliminary results

from federal test sites exploring efficiency gains specific to

integrated LED lighting systems and controls. He concluded that

overall, “LED lighting is [now] easier and cheaper to control than

fluorescent lighting” (Rubinstein 2014).

The federal demonstration sites provided provocative data. Consider

the Goodfellow Building—a 6,100 square foot open office space. It

had a 58 percent savings in LPD with 2 kWh/square feet saved in

energy use. Surveys showed that occupants were generally more

satisfied with the LED lighting, answering positively to questions

about even distribution of light and pleasant brightness in workspaces.

White Paper WP525001EN

Achieving energy efficiency through

integrated lighting controls

Effective March 2015

Two additional test sites—Metcalfe and Summit—explored the

efficiency gains possible from solutions that integrate the sensor

directly with the luminaire. Preliminary findings are summarized in

Figure 3.

Preliminary results: energy savings

Calculated annual energy consumption

Baseline

4.50

Design

Retrofit

–58%

4.00

3.50

Annual EUI (kWh/sq ft/yr)

3.00

2.50

2.00

62% savings

(76% relative

to design)

1.50

1.00

41% savings

0.50

0.00

Metcalfe

Summit

Preliminary energy results: Metcalfe

Minute of day

Very low post-retrofit

energy consumption

Below average pre-retrofit

energy consumption

•

Measured baseline EUI: 2.57 kWh/ft /yr

•

Post-retrofit EUI: 0.98 kWh/ft2/yr

•

‘Design’ baseline EUI: 4.03 kWh/ft /yr

(with all flourescent lamps working)

•

62% savings, and 76% relative

to design

2

2

Figure 3. Preliminary energy consumption savings at

two demonstration sites (source: Rubinstein Lightfair

2014 presentation)

Integrated controls help organizations meet and exceed increasingly

more stringent energy code requirements from basic to complex

with a high level of visual and energy performance. Pre-packaged

solutions both simplify and optimize the code compliance process.

By selecting intelligent lighting control solutions carefully and with

the help of a qualified and trusted vendor, better lighting, improved

efficiency and the full range of benefits from human-centered design

and aesthetic versatility can all be had for a reasonable and quickly

recoverable cost.

Eaton’s Lighting Systems and Solutions business outlined key

considerations for reviewing, researching and planning compliance

under the more stringent standards in the application note:

Understand the differences between ASHRAE 90.1-2010 and

ASHRAE 90.1-2007 and how to ensure code compliance. With handy

pointers to the most relevant and up-to-date information sources,

Mark Gelfo’s article Energy Codes and Lighting Design is another

great place to start the code compliance assessment process.

1400

1200

800

1000

600

400

200

0.00

0

0.00

1400

0.20

1200

0.40

0.20

800

0.60

0.40

1000

0.80

0.60

600

1.00

0.80

400

1.20

1.00

0

1.40

1.20

200

Average weekday LPD (W/sq ft)

1.40

In conclusion, Rubinstein says it best when he notes that:

“Regardless of light source, all lighting should be intelligently

controlled” (Rubinstein 2011). With its increasing potential and

complexity, lighting design is quickly emerging as an art and a

science. At the same time, intelligent and intuitive lighting control

has become a key strategic investment for the commercial sector.

As LED prices continue to fall, there will be increasing interest in

the energy efficiency gains and control versatility options made

possible by integrated lighting control systems. The combined

use of intelligent controls with LED luminaires affords greater

usability and human-centered design—that is, lighting controls

that are more “resilient, efficient, and uplifting” (Rubinstein 2014).

Good lighting can have an incredible impact on human performance

and well-being in the forms of “increased productivity, safety,

security, personal comfort, sales, attendance, and profit” (Kay 2012),

to name just a few.

Highlighted resources

Open office after (installed)

Open office after (measured)

Open office before (installed)

Open office before (measured)

Open office before (design)

Conclusion

The Illuminating Engineering Society LEM-7 Guide to Energy-Saving

Lighting Controls was released in April 2014 in partnership with the

Lighting Controls Association. Written by Craig DiLouie, LC, this brief

guide outlines the latest energy-saving strategies, design considerations, equipment and communication protocols for indoor and

outdoor lighting control systems.

In late 2013, Navigant Research published a lengthy report entitled

Intelligent Lighting Controls for Commercial Buildings. This report

features market analysis through 2020 by region and commercial

building type with a technical focus on networked lighting controls.

Information is available on advances in sensors, ballasts, drivers,

switches, relays, controllers and communications technologies with

profiles of select industry players.

EATON www.eaton.com

5

White Paper WP525001EN

Achieving energy efficiency through

integrated lighting controls

Effective March 2015

About Eaton

Sources

Eaton delivers a broad range of innovative and reliable indoor

and outdoor lighting luminaires and controls solutions specifically

designed to maximize performance, energy efficiency and cost

savings. Offering one of the broadest selections of products in the

industry, we serve customers in the commercial, industrial, retail,

institutional, residential, utility and other markets.

•

Allen, P.S. (2014, January 16). “Lighting commissioning:

Highlighting code compliance.” Consulting Specifying Engineer

(CSE). Retrieved from:

http://www.csemag.com/single-article/lighting-commissioninghighlighting-code-compliance/745e92cf1b8edc76af4689526a0

4cb49.html

As lighting technologies have advanced, we have been at the

forefront of the industry in helping businesses and communities

leverage the latest technologies to improve efficiency, reduce costs,

enrich the quality of life and protect the environment.

•

Chow, M. (2014, May 15). “LED retrofit codes, standards.”

Consulting Specifying Engineer (CSE). Retrieved from:

http://www.csemag.com/single-article/led-retrofit-codes-standards/

cfe87a7208218655a0aa6e833ab5709f.html

Eaton is dedicated to ensuring that reliable, efficient and safe

power is available when it’s needed most. With unparalleled

knowledge of electrical power management across industries,

experts at Eaton deliver customized, integrated solutions to

solve our customers’ most critical challenges.

•

DiLouie, C. (2014, May 20). “Lighting Control and Demand

Response.” Lighting Controls Association. Retrieved from:

http://lightingcontrolsassociation.org/

lighting-control-and-demand-response/

•

Gelfo, M.A. (2013, April 15). “Energy codes and lighting design.”

Consulting Specifying Engineer (CSE). Retrieved from:

http://www.csemag.com/single-article/energy-codes-and-lightingdesign/98ccaa8ffff0b4e042d899698a7f6edd.html

•

Kay, G. (2012, April 13). “Specifying LEDs for commercial use.”

Consulting Specifying Engineer (CSE). Retrieved from:

http://www.csemag.com/single-article/specifying-leds-forcommercial-use/4b2d2563a7c97290287fc721525edcb3.html

•

Navigant Research (2013, December 20). “Sensors and network

control gear for intelligent lighting will reach $2.7 billion in

annual revenue by 2020.” Press release retrieved from: http://

www.navigantresearch.com/newsroom/sensors-and-networkcontrol-gear-for-intelligent-lighting-will-reach-2-7-billion-in-annualrevenue-by-2020

•

Navigant Research (2013, 3Q). “Intelligent lighting controls for

commercial buildings.” Report retrieved from:

http://www.navigantresearch.com/research/

intelligent-lighting-controls-for-commercial-buildings

•

Rubinstein, F. (2014, June 5). “Combining LED lighting and

intelligent controls: achieving a new synergy.” At Lightfair 2014,

Las Vegas, NV.

•

Rubinstein, F. (2011, February 25). “Why fluorescent lighting

isn’t dead.” i4 Energy Seminar Video. Retrieved from:

http://youtu.be/obkqIETtrv0

•

Schultz, J. & Chow, M. (2011, August 16). “Know the newest lighting code.” Consulting Specifying Engineer (CSE). Retrieved from:

http://www.csemag.com/search/search-single-display/know-thenewest-lighting-code/2568e3071a.html

•

National Science Foundation Engineering Research Centers’

Association (NSF-ERC). (2014, May). “Smart Lighting ERC

Achievements: Students’ inaugural bulb replacement effort saves

Rensselaer more than $21,000 annually.” Retrieved from: http://

erc-assoc.org/content/students%E2%80%99-inaugural-bulbreplacement-effort-saves-rensselaer-more-21000-annually

•

U.S. General Services Administration (GSA). (2014, July).

“FINDINGS #15, Integrated daylighting systems.” Report and

summary retrieved from: http://gsa.gov/portal/content/193339

•

U.S. General Services Administration (GSA). (2012, September).

“FINDINGS #2, Occupant responsive lighting.” Report and

summary retrieved from: http://gsa.gov/portal/content/164607

•

Williams, A., Atkinson, B., Garbesi, K., Page, E., & Rubinstein, F.

(2012, January). “Lighting controls in commercial buildings.”

Leukos Vol. 8 No. 3., pp. 161-180.

Our focus is on delivering the right solution for the application.

But, decision makers demand more than just innovative products.

They turn to Eaton for an unwavering commitment to personal

support that makes customer success a top priority. For more

information, visit www.eaton.com/electrical.

Eaton

1000 Eaton Boulevard

Cleveland, OH 44122

United States

Eaton .com

© 2015 Eaton

All Rights Reserved

Printed in USA

Publication No . WP525001EN / Z16243

March 2015

Eaton is a registered trademark.

All other trademarks are property

of their respective owners.