A Remarkably Simple One-Step Procedure for the Preparation of

advertisement

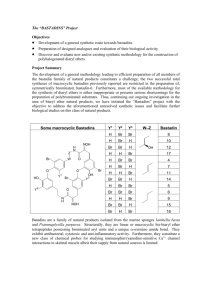

LETTER 2309 A Remarkably Simple One-Step Procedure for the Preparation of a-Bromo-a,b-Unsaturated Carbonyl Compounds a,b SimplePrepar tionofa-Bromo-a,b-UnsaturatedCarbonylCompounJyothi, Divya ds S. HariPrasad*a a Abstract: An easy and convenient one-step procedure for the conversion of a,b-unsaturated carbonyl compounds into their corresponding bromo-enones using NBS–Et3N·3HBr in the presence of potassium carbonate in dichloromethane at 0 °C to room temperature under very mild conditions in high yields and significantly shorter times, is reported. Key words: NBS–Et3N·3HBr, a-bromo-a,b-unsaturated carbonyl compounds, bromination, mild conditions a-Bromo-a,b-unsaturated carbonyl compounds form an important class of compounds in synthetic organic chemistry. Their versatility lies in both the synthesis of a-substituted enones1 and in their ability to serve as a-ketovinyl anion equivalents.2 These class of compounds are potential starting materials for the synthesis of natural products and some of the bromo-enones are themselves also obtained in nature.3 They are employed in the construction of a wide variety of biologically and medicinally important products,4 and there is a wealth of literature available to mark its importance in natural product chemistry. To name a few, this type of compound has been used in the synthesis of the carbon framework of the guanacastepene family of natural products,5 in the synthesis of taxane diterpenes,6a in dihydrojasmones,6b and in the synthesis of pentenomycins I-III.7 Although the preparation of these compounds is well documented in the literature, a simpler, milder and better alternative will always be advantageous to the synthetic chemist. a-Bromo-a,b-unsaturated carbonyl compounds can be prepared by various methods. The most common being one-pot bromination–dehydrobromination employing bases such as triethylamine,8 pyridine,9 or sodium bicarbonate.10 Other brominating agents used are: phenylselenium bromide,11 pyridinium bromide per bromide,12 sodium bromide–Oxone,13a dimethyldioxirane and metal halides/amberlyst 1513b or dimethylbromosulfonium bromide.14 Alternatively, conversion into the silylenol ethers and subsequently into 1,1-dibromo-2-silyloxycyclopropane followed by elimination to form halomethylsilane has been described.15 SYNLETT 2009, No. 14, pp 2309–2311xx. 209 Advanced online publication: 03.08.2009 DOI: 10.1055/s-0029-1217726; Art ID: D06409ST © Georg Thieme Verlag Stuttgart · New York The reported methods can entail low yields, difficulty in handling hazardous bromine as well as maintaining its stoichiometric ratio, expensive reagents, longer reaction times, multiple steps, cumbersome product isolation and environmental pollution. Moreover, the replacement of toxic organic reagents is one of the important goals in green chemistry.16 In a continuation of our studies on the synthesis and reactions of some novel cyclic vinyl silanes,17 we needed supplies of a-bromo-a,b-unsaturated carbonyl compounds, which could be used as starting materials for the preparation of olefinic organosilicon compounds. Direct access to a-bromo-methylcyclohexenone (2a) by the usual protocol of bromination–dehydrobromination was not feasible even under different conditions and solvents because of its marked tendency to aromatize even under the mildest alkaline conditions.18 In our efforts to identify an efficient approach, we found two useful methods involving the use of DMP19 and TBATB.20 However, the expensive reagents, availability, time duration, scalability and isolation methods were problematic. So designing a simple and efficient method for the preparation of the starting material was necessary. Among other brominating agents, N-bromosuccinimide (NBS) should be considered the reagent of first choice because of its ready availability and ease of handling. Heasley21 illustrated the effect of NBS on the bromination of a,b-unsaturated ketones, and isolated significantly lower amounts of the dibromides. This prompted us to choose a suitable brominating agent that can enhance the efficiency of the dibromide formation. Due to the potential of NBS–Et3N·HBr as a brominating agent, we expected to form a-bromo-a,b-unsaturated carbonyl compounds upon bromination of ketones with the above reagent. Thus, the procedure22 developed in this study involves the reaction of a,b-unsaturated ketones with NBS–Et3N·3HBr in anhydrous dichloromethane at 0 °C, followed by treatment with potassium carbonate and stirring at room temperature to give the bromo-ketones in very high yields. Surprisingly when we extended the same method to substrates 1g, 1h and 1i (Table 1), we could isolate the desired products in good yields after simple workup and chromatographic purification. In conclusion, we describe in this paper, a versatile, simple and environmentally friendly one-step procedure for the conversion of a,b-unsaturated ketones into their corre- This document was downloaded for personal use only. Unauthorized distribution is strictly prohibited. Department of Studies in Chemistry, Central College Campus, Bangalore University, Bangalore 560001, India E-mail: hariprasad@bub.ernet.in b Department of Organic Chemistry, Indian Institute of Science, Bangalore 560012, India Received 2 March 2009 LETTER D. Jyothi, S. HariPrasad sponding bromo-enones. The very mild method uses NBS–Et3N·3HBr in the presence of potassium carbonate in anhydrous dichloromethane at 0 °C to room temperature, and gives high yields in short reaction times. Table 1 a-Bromination of a,b-Unsaturated Carbonyl Compounds using NBS–Et3N·3HBr Entry Substrate Time (min) Producta O Yield (%)b O a Br 25 1a 88 2a O O b Br 22 1b 83 2b O O c 24 1c Br 86 Br 89 2c O O d 24 1d 2d O O Br e 32 1e 89 2e O O Br f 28 1f 81 2f O g O Br 30 O O 1g 2g O HN h O O N H O 76 N H O 2h O O i Br HN 35 1h Me 78 Me N 30 N O 76 N Me Me 1i Br N 2i a The products were characterized by melting points, IR, 1H NMR, and 13C NMR spectroscopy, and mass spectrometry. b Isolated yield. Synlett 2009, No. 14, 2309–2311 © Thieme Stuttgart · New York Acknowledgment We are thankful to the Organic Chemistry and NMR departments, Indian Institute of Science, Bangalore. Grateful thanks are due to the University Grants Commission and the Department of Science and Technology, New Delhi, India for finacial assistance. References and Notes (1) (a) Kabat, M.; Kiegiel, J.; Cohen, N.; Toth, K.; Wovkulich, P. M.; Uskokovic, M. R. Tetrahedron Lett. 1991, 32, 2343. (b) Smith III, A. B.; Branca, S. J.; Guaciaro, M. A.; Wovkulich, P. M.; Korn, A. Org. Synth. Coll. Vol. VII; Wiley: New York, 1990, 271. (c) Liebeskind, L. S.; Wang, J. Tetrahedron Lett. 1990, 31, 4293. (d) Atsuta, H.; Fugiwara, K.; Murai, A. Synlett 1997, 307. (e) Negishi, E. I.; Owezarczyk, Z. R.; Swanson, D. R. Tetrahedron Lett. 1991, 32, 4453. (2) (a) Finici, J.; Depezay, J. C. Tetrahedron Lett. 1969, 10, 4794. (b) Guaciaro, M. A.; Wovkulich, P. M.; Smith III, A. B. Tetrahedron Lett. 1978, 19, 4661. (c) Bachki, A.; Foubelo, F.; Yus, M. Tetrahedron Lett. 1997, 53, 4921. (3) Gribble, G. W. In Progress in the Chemistry of Organic Natural Products; Herz, W.; Kirby, G. W.; Moore, R. E.; Steglich, W.; Tam, C., Eds.; Springer-Verlag: Vienna, 1996, 17–22; and references cited therein. (4) Moser, W. H.; Feltes, L. A.; Sun, L.; Giese, M. W.; Farrell, R. W. J. Org. Chem. 2006, 71, 6542. (5) Shipe, W. D.; Sorensen, E. J. Org. Lett. 2002, 4, 2063. (6) (a) Paquette, L. A.; Suz Bailey, S.; Montgomery, F. J. J. Org. Chem. 1995, 60, 897. (b) Crombie, L. Chemistry of Pyrethrins, Pyrethrum Flowers: Production, Chemistry, Toxicology and Uses; Cardia, J. E.; Quistad, G. B., Eds.; Oxford University Press: Oxford, 1995. (7) Smith III, A. B.; Branca, S. J.; Pilla, N. N.; Guaciaro, M. A. J. Org. Chem. 1982, 47, 1855. (8) Dunn, G. L.; Dipasquo, V. J.; Hoover, J. R. E. J. Org. Chem. 1968, 33, 1454. (9) Shih, C.; Fritzen, E. L.; Swenton, J. S. J. Org. Chem. 1980, 45, 4462. (10) Janssen, C. G. M.; Simons, L. H. J. G.; Godefroi, E. F. Synthesis 1982, 389. (11) Ley, S. V.; Whittle, A. J. Tetrahedron Lett. 1981, 22, 3301. (12) Dauben, W. G.; Warshawsky, A. M. Synth. Commun. 1988, 18, 1323. (13) (a) Dieter, R. K.; Nice, L. E.; Velu, S. E. Tetrahedron Lett. 1996, 37, 2377. (b) Righi, G.; Boricelli, P.; Sperandio, A. Tetrahedron Lett. 1999, 40, 5889. (14) Bakker, B. H.; Chow, Y. L. Can. J. Chem. 1982, 60, 2268. (15) Amice, P.; Blanco, L.; Conia, J. M. Synthesis 1976, 196. (16) Anastas, P.; Williamson, T. Green Chemistry, Frontiers in Benign Chemical Synthesis and Procedures; Oxford Science Publications: Oxford, 1998, . (17) (a) HariPrasad, S.; Nagendrappa, G. Tetrahedron 1993, 49, 3387. (b) HariPrasad, S.; Nagendrappa, G. Indian J. Chem., Sect. B: Org. Chem. Incl. Med. Chem. 1997, 36, 691. (c) HariPrasad, S.; Nagendrappa, G. Indian J. Chem., Sect. B: Org. Chem. Incl. Med. Chem. 1997, 36, 1016. (d) Divya, J.; Hariprasad, S. Synth. Commun. 2009, 39, 875. (18) Belmont, S. T.; Paquette, L. A. J. Org. Chem. 1985, 50, 4102. (19) Ramanarayanan, G. V.; Vidyanand, G. S.; Akamanchi, K. G. Synlett 2002, 2059. (20) Bose, G.; Barua, B. P. M.; Chaudhuri, M. K.; Kalita, D.; Khan, A. T. Chem. Lett. 2001, 4, 290. (21) Heasley, V. L.; Louie, T. J.; Luttrull, D. K.; Millar, M. D.; Moore, H. B.; Nogales, D. F.; Sauerbrey, A. M.; Shevel, A. This document was downloaded for personal use only. Unauthorized distribution is strictly prohibited. 2310 Simple Preparation of a-Bromo-a,b-Unsaturated Carbonyl Compounds B.; Shibuya, T. Y.; Stanley, M. S.; Shellhamer, D. F.; Heasley, G. E. J. Org. Chem. 1988, 53, 2199. (22) Typical Procedure: To a stirred solution of 3-methylcyclohex-2-en-1-one (1a; 2.5 g, 13.23 mmol) in anhydrous CH2Cl2 (25 mL) were added NBS (14 mmol), Et3N·3HBr (23 mmol) and K2CO3 (40 mmol) at 0 °C. After 10 min the reaction mixture was slowly brought to r.t. and stirring was continued. The reaction was complete within 25 min as monitored by GC [SE-30 SS; 2m × 1/8¢¢ column on Shimadzu 14-B/Mayura 9800 gas chromatographs]. The residual solid was filtered off and the solid residue was washed with anhydrous CH2Cl2 (15 mL). The combined filtrate was concentrated under vacuum and the crude 2311 product was purified by chromatography (silica gel; EtOAc– hexane, 1:4) to afford, after concentration, the product 2a as light-yellow oil in 88% yield. IR (neat): 2920 (S), 1695 (S), 1605 (S), 1255 (S). 1H NMR (400 MHz, CDCl3): d = 2.59 (t, J = 6.7 Hz, 2 H), 2.52 (t, J = 6 Hz, 2 H), 2.18 (s, 3 H), 2.05– 1.97 (m, 2 H). 13C NMR (400 MHz, CDCl3): d = 190.9 (C=O), 160.3 (C), 122.7 (CH), 37.6 (CH2), 25.9 (CH3), 21.8 (CH2). GCMS (Shimadzu GC-17A coupled to Shimadzu GC-MS QP 5050 A with capillary column: BP 5, length: 30 m): m/z (%) = 190 (10), 188 (15), 162 (25), 160 (30), 132 (5), 127 (7), 190 (12), 93 (4), 83 (4), 81 (30), 79 (25), 76 (5), 66 (10), 52 (10), 67 (8), 63 (19), 56 (5), 55 (13), 53 (80), 51 (47), 50 (32), 43 (13), 42 (100), 41 (88), 40 (60). This document was downloaded for personal use only. Unauthorized distribution is strictly prohibited. LETTER Synlett 2009, No. 14, 2309–2311 © Thieme Stuttgart · New York