2.61 Internal Combustion Engines MIT OpenCourseWare Spring 2008 rms of Use, visit:

advertisement

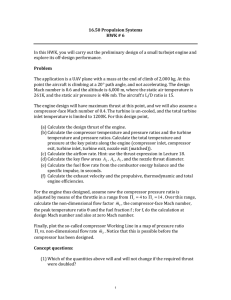

MIT OpenCourseWare http://ocw.mit.edu 2.61 Internal Combustion Engines Spring 2008 For information about citing these materials or our Terms of Use, visit: http://ocw.mit.edu/terms. Engine Turbo/Super Charging Super and Turbo-charging Why super/ turbo-charging? • Fuel burned per cycle in an IC engine is air limited – (F/A)stoich = 1/14.6 Torq = ηf m f QHV 2πnR Power = Torq ⋅ 2πN m f = F η V ρa,0 VD A ( ) ηf,ηv– fuel conversion and volumetric efficiencies mf – fuel mass per cycle QHV– fuel heating value nR – 1 for 2-stroke, 2 for 4-stroke engine N – revolution per second VD – engine displacement ρa,0 – air density Super/turbo-charging: increase air density Super- and Turbo- Charging Purpose: To increase the charge density • Supercharge: compressor powered by engine output – No turbo-lag – Does not impact exhaust treatment – Fuel consumption penalty • Turbo-charge: compressor powered by exhaust turbine – Uses ‘wasted’ exhaust energy – Turbo- lag problem – Affects exhaust treatment • Intercooler – Increase charge density (hence output power) by cooling the charge – Lowers NOx emissions Charge-air pressure regulation with wastegate on exhaust gas end. 1.Engine, 2. Exhaust-gas turbochager, 3. Wastegate Exhaust-gas turbocharger for trucks 1.Compressor housing, 2. Compressor impeller, 3. Turbine housing, 4. Rotor, 5. Bearing housing, 6. inflowing exhaust gas, 7. Out-flowing exhaust gas, 8. Atmospheric fresh air, 9. Pre-compressed fresh air, 10. Oil inlet, 11. Oil return Images removed due to copyright restrictions. Please see illustrations of "Charge-air Pressure Regulation with Wastegate on Exhaust Gas End", and "Exhaust-gas Turbocharger for Trucks." In the Bosch Automotive Handbook. London, England: John Wiley & Sons, 2004. From Bosch Automotive Handbook Compressor: basic thermodynamics Compressor efficiency ηc 2 W ideal ηc = W W m actual 1 ⎞ ⎛T ′ 2 ⎜ c p T1 Wideal = m − 1⎟ ⎟ ⎜ T1 ⎝ ⎠ T P2 Ideal process 2’ 1 2 γ−1 T2′ ⎛ P2 ⎞ γ = ⎜⎜ ⎟⎟ T1 ⎝ P1 ⎠ P1 Actual process s γ−1 ⎛ ⎞ ⎜ ⎟ γ ⎛ ⎞ P 1 2 c p T1⎜ ⎜ ⎟ W m − 1⎟ actual = ⎜ ⎟ ηc ⎜⎜ ⎝ P1 ⎠ ⎟⎟ ⎝ ⎠ W T2 = T1 + actual cp m Turbine: basic thermodynamics Turbine efficiency ηt 4 W ηt = actual W W 3 ideal ⎛ T ′⎞ ⎜1− 4 ⎟ W = m c T ideal p 3⎜ T3 ⎟ ⎝ ⎠ m T P3 γ−1 ⎛ P4 ⎞ γ ⎜ ⎟ T4′ =⎜ ⎟ T3 ⎝ P3 ⎠ Ideal process P4 3 4 4’ Actual process s γ−1 ⎞ ⎛ ⎜ ⎛P ⎞ γ ⎟ c p T3 ⎜1− ⎜ 4 ⎟ ⎟ Wactual = ηt m ⎜ ⎟ ⎟⎟ ⎜⎜ ⎝ P3 ⎠ ⎝ ⎠ W T4 = T3 − actual cp m Properties of Turbochargers • Power transfer between fluid and shaft ∝ RPM3 – Typically operate at ~ 60K to 120K RPM • RPM limited by centrifugal stress: usually tip velocity is approximately sonic • Flow devices, sensitive to boundary layer (BL) behavior – Compressor: BL under unfavorable gradient – Turbine: BL under favorable gradient Typical super/turbo-charged engine parameters • Peak compressor pressure ratio ≈ 3.5 • BMEP up to 22 bar • Limits: – compressor aerodynamics – cylinder peak pressure – NOx emissions Compressor/Turbine Characteristics • Delivered pressure P2 ,RT ,P ,N,D,μ, γ, geometric ratios) • P2 = f(m 1 1 • Dimensional analysis: – 7 dimensional variables → (7-3) = 4 dimensionless parameters (plus γ and geometric ratios) ⎛ P2 ⎞ N m ⎜⎜ ⎟⎟ = f( , ,Re, γ, geometric ratios) γRT1 / D ⎛ P1 ⎞ ⎝ P1 ⎠ ⎜⎜ ⎟⎟ RT1D 2 ⎝ RT1 ⎠ Velocity Density Velocity High Re number flow →weak Re dependence For fixed geometry machinery and gas properties T1 ⎞ ⎛ P2 ⎞ ⎛⎜ N m ⎟ ⎜⎜ ⎟⎟ = f , P1 ⎟ ⎝ P1 ⎠ ⎜ ⎝ T1 ⎠ Compressor Map 3.4 7250 3.2 6960 3.0 72% 70% 2.6 2.0 65% 60% it 2.4 2.2 6530 74% Su rg el im Pressure ratio 2.8 75% 6070 1.8 5550 1.6 4840 1.4 4025 N/ T1 1.2 1.0 2650 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 . "Corrected" Flow rate m T1/P1 Figure by MIT OpenCourseWare. Adapted from Haddad, Sam David, and Watson, N. Principles and Performance in Diesel Engineering. Chichester, England: Ellis Horwood, 1984. T1= inlet temperature (K); P1= inlet pressure (bar); N = rev. per min.; m = mass flow rate (kg/s) (From “Principles and Performance in Diesel Engineering,” Ed. by Haddad and Watson) Compressor stall and surge • Stall – Happens when incident flow angle is too large (large Vθ/Vx) – Stall causes flow blockage • Surge – Flow inertia/resistance, and compression system internal volume comprise a LRC resonance system – Oscillatory flow behave when flow blockage occurs because of compressor stall ¾ reverse flow and violent flow rate surges Turbine Map 2.8 2.6 π tTS = .70 2.4 2.0 1.8 .65 Pressure ratio 2.2 1.6 .6 0 4000 3000 2500 .40 1.2 1.0 3500 5 N T03 1500 500 0.5 1.0 .5 1.4 .50 1.5 2.0 . Flow rate m T03/P03 2.5 3.0 Figure by MIT OpenCourseWare. Adapted from Haddad, Sam David, and Watson, N. Principles and Performance in Diesel Engineering. Chichester, England: Ellis Horwood, 1984. T03=Turbine inlet temperature(K); P03 = Turbine inlet pressure(bar); P4= Turbine outlet pressure(bar); N = rev. per min.; m = mass flow rate (kg/s) (From “Principles and Performance in Diesel Engineering,” Ed. by Haddad and Watson) Compressor Turbine Matching Exercise • For simplicity, take away intercooler and wastegate • Given engine brake power ) and RPM, output (W E compressor map, turbine map, and engine map • Find operating point, i.e. air flow ( m a ), fuel flow rate ( m f ) turbo-shaft revolution per second (N), compressor and turbine pressure ratios (πc and πt) etc. 1 4 T C 2 m f 3 Engine W E Q L Compressor/ turbine/engine matching solution Procedure : 1. Guess πc ; can get engine inlet conditions : γ−1 ⎡ ⎤ γ ⎥ T1 ⎢ P2 = πc P1 T2 = − 1⎥ ⎢(πc ) ηc ⎢ ⎥ ⎢⎣ ⎥⎦ 2. Then engine volumetric efficiency calibration a that can be ' swallowed' will give the air flow m Compressor 3.4 7250 3.2 6960 3.0 72% 70% 2.6 6530 74% 2.4 it 65% 60% rg e lim 2.2 2.0 75% Su Pressure ratio 2.8 a and πc , the compressor speed N can be 3. From m 6070 1.8 5550 1.6 obtained from the compressor map f may be obtained from the 4. The fuel flow rate m 4840 1.4 4025 N/ T1 1.2 1.0 2650 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 . "Corrected" Flow rate m T1/P1 Figure by MIT OpenCourseWare. Adapted from Haddad, Sam David, and Watson, N. Principles and Performance in Diesel Engineering. Chichester, England: Ellis Horwood, 1984. 2.8 2.6 2.4 η tTS = .70 6. Guess π t , then get turbine speed Nt from turbine map 7. Determine turbine power from turbine efficiency on map ⎡ = η ⎢1− ⎛⎜ 1 W t t⎢ ⎜ ⎢ ⎝ πt ⎣ 2.0 .65 1.8 4000 .60 1.0 3000 1500 500 0.5 1.0 ⎟ ⎟ ⎠ ⎥ ⎥ ⎦ =W and N = N 8.Iterate on the values of πc and π t until W t c t c 3500 2500 1.2 γ−1 ⎤ ⎞ γ ⎥ .5 5 N T03 .4 0 Pressure ratio 2.2 1.4 5. Engine exhaust temperature T3 may be obtained from energy balance (with known engine mech. eff. ηM ) a +m f )c p T3 = m a c p T2 + m f LHV − WE − Q (m L ηM Turbine 1.6 engine map : =m ,A/F) f LHV ηf (RPM,W W E E .50 1.5 2.0 . Flow rate m T03/P03 2.5 3.0 Figure by MIT OpenCourseWare. Adapted from Haddad, Sam David, and Watson, N. Principles and Performance in Diesel Engineering. Chichester, England: Ellis Horwood, 1984. Compressor/ Engine/ Turbine Matching 0.65 3.0 0.67 2.5 0.60 0.70 0.55 ns ad Co nst ant Co t lo tan sp e ed it el im 2.0 Su rg Pp/P1 0.72 • Mass flows through compressor, engine, turbine and wastegate have to be consistent • Turbine inlet temperature consistent with fuel flow and engine power output • Turbine supplies compressor work • Turbine and compressor at same speed 1.5 T C 1.0 0 1 2 3 4 m T1 p1 Figure by MIT OpenCourseWare. Adapted from Haddad, Sam David, and Watson, N. Principles and Performance in Diesel Engineering. Chichester, England: Ellis Horwood, 1984. Compressor characteristics, with airflow requirements of a four-stroke truck engine superimposed. (From “Principles and Performance in Diesel Engineering,” Ed. by Haddad and Watson) Inter- Cooler Wastegate Engine Advanced turbocharger development Electric assisted turbo-charging • Concept – Put motor/ generator on turbo-charger – reduce wastegate function • Benefit InterCooler – increase air flow at low engine speed – auxiliary electrical output at part load Motor/ Generator T C Wastegate Engine Battery Advanced turbocharger development Electrical turbo-charger Battery • Concept – turbine drives generator; compressor driven by motor • Benefit – decoupling of turbine and compressor map, hence much more freedom in performance optimization – Auxiliary power output – do not need wastegate; no turbo-lag C Motor InterCooler Engine T Generator Advanced turbocharger development Challenges • Interaction of turbo-charging system with exhaust treatment and emissions – Especially severe in light-duty diesel market because of low exhaust temperature • Cost