FS-6700-7 (11/99) U.S. Department of Agriculture 1. WORK PROJECT/ACTIVITY 2. LOCATION

advertisement

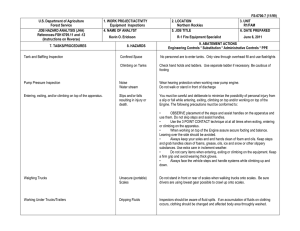

FS-6700-7 (11/99) U.S. Department of Agriculture Forest Service JOB HAZARD ANALYSIS (JHA) References-FSH 6709.11 and -12 (Instructions on Reverse) 1. WORK PROJECT/ACTIVITY 2. LOCATION Working on and around engine apperatus. 4. NAME OF ANALYST 7. TASKS/PROCEDURES Entering, exiting, and/or climbing on top of the apperatus. Madeline Levaggi, Thomas Fielden FEO, SFEO 8. HAZARDS Slips and/or falls resulting in injury or death. Exhaust pipe burns. Opening compartment doors. Unsecured items falling toward you. Oak Knoll 6. DATE PREPARED 04/28/2004 9. ABATEMENT ACTIONS Engineering Controls * Substitution * Administrative Controls * PPE You must be careful and deliberate to minimize the possibility of personal injury from a slip or fall while entering, exiting, climbing on top and/or working on top of the Engine. The following precautions must be conformed to: Sharp edges. Various 5. JOB TITLE 3. UNIT OBSERVE placement of the steps and assist handles on the apperatus and use them. Do not skip steps and assist handles. Use the 3 POINT CONTACT techniqueat at all times when exiting, entering or climbing on the apperatus. When working on top of the Engine assure secure footing and balance. Leaning over the side sould be avoided. Always keep your soles and and hands clean of foam and oils. Keep steps and assist handles clean of foams, grease, oils, ice and snow or other slippery substances. Use extra care in inclament wheather. Do not carry items when entering, exiting or climbing on the Engine. Keep a firm grip and avoid wearing thick gloves. Always face the vehicle steps and handle systems while climbing up and down. If climbing into cab or compartments use precautions to avoid sharp edges/coners of doors that may be open or are being opened. The exhaust pipe may be very HOT if the engine has been or is running. Do not climb up passenger and/or drivers side to get to the top of the engine if you have verticaly mouted exhaust systems. The only access to the top of the engine is located at thr rear of the engine uless vehicle has been modified. Secure all items in compartments to avoid this occurring. Make sure tools are secured with appropriate tie downs before closing tool compartments. All tools must have guards on them. When opening compartments be aware that items may have shifted and may fall toward you. Be prepared! Do not overstuff compartments and store small item in Compartment srtuts breaking Using safety restraints proprly. Not wearing seatbelts or not wearing them properly. Secure doors. Potential for ejection and injury. Moving engine. Injury or damage to equipment. Hearing damage or burns. Working around running engine or pump. Windows and mirrors. Obstructed vision. Exhaust Carbon monoxide poiseneng. Putting gear on/off the top of the engine Injury from strains or falling off the engine. containers. Compartment struts may give out or break causing an opened compartment door to unexpectedly drop down possibly causing head, neck or other injury. Do not trust the struts wholeheartedly. Inspect struts on a regular basis. Over stuffing the compartment can facillitate strut damage. Do not force a compartment closed, reorganize them or remove items so they can be easily closed. Make sure that you and your passengers wear their safetybelts properly. Be sure that lap belts fit snugly and as low on the hips as possible. Do not allow people to ride on top, on the bumper or the cargo area of the vehicle, even for a short distance. Never use a single belt for more than one person or across more than one seating position. Use the shoulder belt on the outside of the shoulder only. Never wear the shoulder belt under the shoulder. Remember if seatbelts are not used properly, the chances of you or your passenger being injured in a collision are graetly increased. Be sure to make sure all doors and compartment doors are closed and secure. Assure engine compartment is strapped down. Locking the doors may be a mitigation factor. Before moving the engine do a walk around to assure all compartments are secure and all personnel are accounted for. Wear earplugs. Keep hands/body parts away from hot engine parts. Don’t touch manifold on pumps or parts of a running engine. Inspect windows and mirrors daily for cleanliness and keep them clean. It is the drivers responsibility to assure propper adjustment of mirrors. Avoid moving the mirrors inadvertantly while working around a stationary vehicle. Notify the driver if you mistakenly move a mirror. Avoid breathing vehicle exhaust. If unavoidable cycle into fresh air as much as possible. It is preferable to use 2 people to load/unload items, on top and on the ground. When lowering brace your self and lower item to person on the ground, do not release until receiving person says “GOT IT”. If working alone , non-fragile items can be droped off the engine on to the ground. DO NOT attemt to carry item as you climb up or down if it compramises your minimum of your three point climbing method. If item exceeds your lifting capabilities get help. Performing inspections. Unsafe practices. Backing Engine. Unsafe practices. Parking Engine. Unsafe practices. 10. LINE OFFICER SIGNATURE Previous edition is obsolete DO NOT place hands or other body parts near the moving parts of the motor or pump. Diesel fuel injectors are under extreme pressure and may if disturbed cause great harm. The fan may come on without warning. Avoid burns from checking lubricants that may be hot. When PTO is enguaged DO NOT touch moving parts located under the Engine. Use backer whenever available. Backer will establish visual contact with the driver, in the mirror pre established with the driver. Backer needs to be in sight of the driver at all times and use clear hand signals. Backer needs to stand far enough behind the engine to see obstacles and so the driver can react if backer abruptly stops. Do not go behind engine until backup lights and backup warning are off. Park facing out toward your escape route. Always chock your vehicle when it is parked. 11. TITLE (over) 12. DATE JHA Instructions (References-FSH 6709.11 and .12) The JHA shall identify the location of the work project or activity, the name of employee(s) involved in the process, the date(s) of acknowledgment, and the name of the appropriate line officer approving the JHA. The line officer acknowledges that employees have read and understand the contents, have received the required training, and are qualified to perform the work project or activity. Blocks 1, 2, 3, 4, 5, and 6: Self-explanatory. Block 7: Identify all tasks and procedures associated with the work project or activity that have potential to cause injury or illness to personnel and damage to property or material. Include emergency evacuation procedures (EEP). Block 8: Identify all known or suspect hazards associated with each respective task/procedure listed in block 7. For example: a. Research past accidents/incidents. b. Research the Health and Safety Code, FSH 6709.11 or other appropriate literature. Emergency Evacuation Instructions (Reference FSH 6709.11) Work supervisors and crew members are responsible for developing and discussing field emergency evacuation procedures (EEP) and alternatives in the event a person(s) becomes seriously ill or injured at the worksite. Be prepared to provide the following information: a. Nature of the accident or injury (avoid using victim's name). b. Type of assistance needed, if any (ground, air, or water evacuation). c. Location of accident or injury, best access route into the worksite (road name/number), identifiable ground/air landmarks. d. Radio frequencies. e. Contact person. f. Local hazards to ground vehicles or aviation. g. Weather conditions (wind speed & direction, visibility, temperature). h. Topography. i. Number of individuals to be transported. j. Estimated weight of individuals for air/water evacuation. c. Discuss the work project/activity with participants. d. Observe the work project/activity. The items listed above serve only as guidelines for the development of emergency evacuation procedures. e. A combination of the above. Block 9: Identify appropriate actions to reduce or eliminate the hazards identified in block 8. Abatement measures listed below are in the order of the preferred abatement method: a. Engineering Controls (the most desirable method of abatement). For example, ergonomically designed tools, equipment, and furniture. JHA and Emergency Evacuation Procedures Acknowledgment We, the undersigned work leader and crew members, acknowledge participation in the development of this JHA (as applicable) and accompanying emergency evacuation procedures. We have thoroughly discussed and understand the provisions of each of these documents: SIGNATURE b. Substitution. For example, switching to high flash point, non-toxic solvents. Work Leader c. Administrative Controls. For example, limiting exposure by reducing the work schedule; establishing appropriate procedures and practices. d. PPE (least desirable method of abatement). For example, using hearing protection when working with or close to portable machines (chain saws, rock drills, and portable water pumps). e. A combination of the above. Block 10: The JHA must be reviewed and approved by a line officer. Attach a copy of the JHA as justification for purchase orders when procuring PPE. Blocks 11 and 12: Self-explanatory. DATE SIGNATURE DATE