Reactor optimization of volatilized p-xylene metabolism by Barbara Christine Vaughn

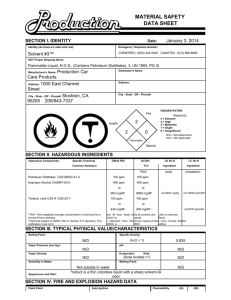

advertisement